Aug . 14, 2024 13:02 Back to list

Effective Strategies for Ensuring Dust Sealing in Industrial Environments and Equipment Maintenance

Understanding Dust Sealing and Its Importance

In various industries and applications, the control of dust is paramount to ensure the longevity and reliability of equipment, the safety of workers, and the overall efficiency of operations. Dust sealing plays a crucial role in achieving these goals by providing effective barriers against the infiltration of particulates into sensitive environments. This article will explore the significance of dust sealing, its applications, and the technologies used to enhance dust protection.

The Importance of Dust Sealing

Dust is more than just a nuisance; it can significantly impact the performance and durability of machinery and electronics. For instance, in manufacturing facilities, the presence of dust can lead to equipment malfunctions, increased wear on moving parts, and even catastrophic failures. In environments such as clean rooms, dust contamination can compromise product quality and safety, making effective dust sealing essential.

Employing proper dust sealing techniques helps reduce maintenance costs, minimizes downtime, and ensures compliance with health and safety regulations. Additionally, in industries like food and pharmaceuticals, where cleanliness is critical, maintaining a dust-free environment is not just about operational efficiency; it is also about meeting stringent quality standards.

Applications of Dust Sealing

Dust sealing is utilized across numerous sectors

. In the construction industry, for instance, dust control measures are implemented to protect equipment and provide a safe working environment. Similarly, in mining operations, dust sealing technologies are employed to safeguard machinery from abrasive dust generated during drilling and transportation processes.dust sealing

In the electronics sector, dust sealing is imperative for devices such as computers, smartphones, and industrial sensors. Enclosures designed with dust-sealing features help maintain functionality and prolong the life of electronic components by preventing dust ingress. Even in the automotive industry, effective dust sealing contributes to improved vehicle performance and longevity, enhancing the overall driving experience.

Technologies and Innovations in Dust Sealing

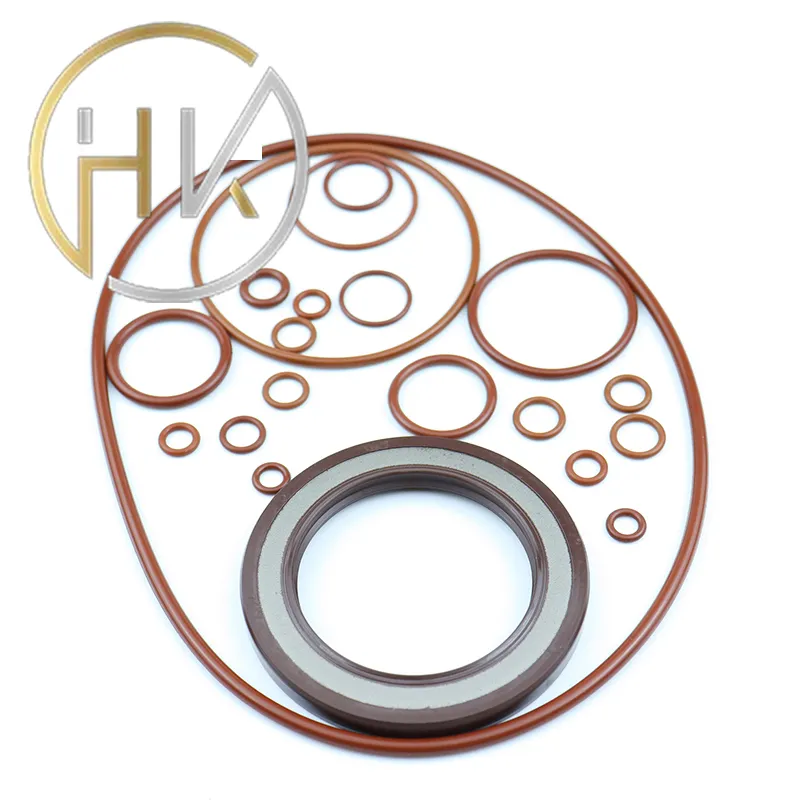

The technology behind dust sealing has evolved significantly, incorporating various materials and design innovations. For example, rubber gaskets and seals are commonly used to create tight barriers against dust. These materials can be engineered to withstand extreme conditions, including temperature fluctuations and chemical exposure.

Advanced sealing technologies, such as labyrinth seals and brush seals, offer enhanced dust protection. Labyrinth seals employ a complex series of grooves and channels that force dust particles to navigate a longer path, greatly reducing the likelihood of ingress. Brush seals, on the other hand, use flexible bristles that can adapt to irregular surfaces, providing a tight seal against dust while allowing for some movement or vibration.

Furthermore, the integration of smart technologies into dust sealing solutions is on the rise. Sensors can now be embedded within sealing systems to monitor the integrity of seals in real-time. This proactive approach allows for timely maintenance and repairs, reducing the risk of dust infiltration before it becomes a significant problem.

Conclusion

Dust sealing is a critical component in maintaining operational efficiency, protecting valuable equipment, and ensuring the safety and quality of products across various industries. As technology continues to advance, the importance of effective dust sealing will only increase. Businesses must prioritize dust control strategies to safeguard their operations, protect their assets, and comply with industry regulations. By investing in innovative sealing technologies, organizations can achieve a cleaner, safer, and more productive working environment, ultimately leading to enhanced performance and profitability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories