12-р сар . 18, 2024 00:05 Back to list

Hydraulic Oil Seal Cost and Market Trends Analysis

Understanding the Price of Hydraulic Oil Seals

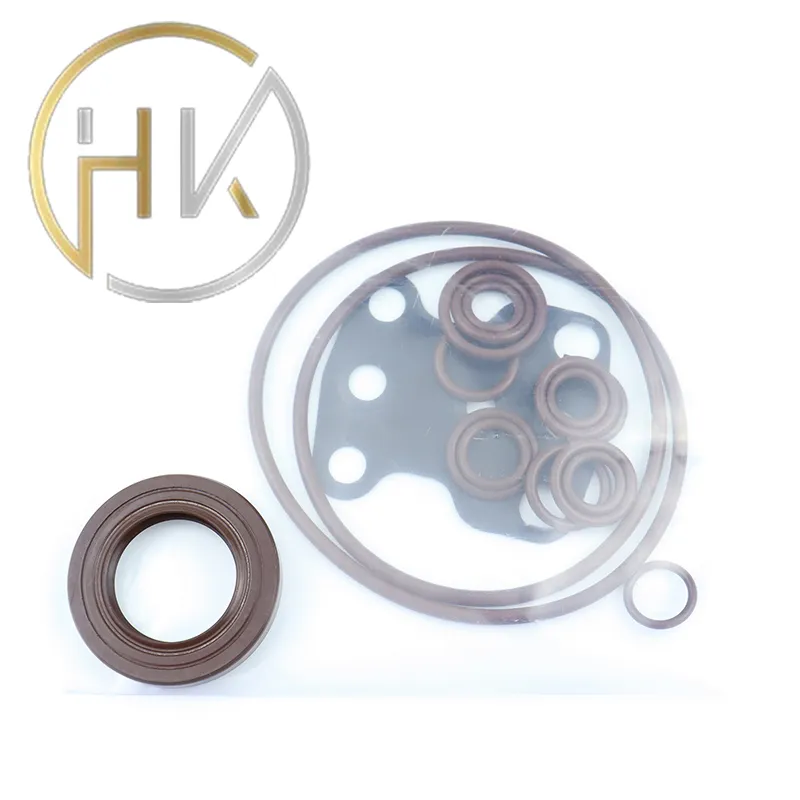

Hydraulic oil seals play a crucial role in the functioning of hydraulic systems, providing essential leakage control and enabling the smooth operation of machinery and equipment. These components make up a vital part of hydraulic cylinders, pumps, and motors, where they prevent the escape of hydraulic fluid and protect against contaminants. As industries increasingly rely on hydraulic systems for their operations, understanding the pricing of hydraulic oil seals becomes essential for businesses aiming to manage their costs and ensure effective operation.

Factors Affecting the Price

1. Material Composition Hydraulic oil seals are manufactured from various materials, including rubber, polyurethane, and thermoplastics. The choice of material significantly impacts the price, with more durable and temperature-resistant materials often commanding a higher cost. For instance, seals made from fluorocarbon rubber (FKM) are generally more expensive than those made from standard nitrile rubber (NBR) due to their enhanced chemical resistance and higher temperature tolerance.

2. Design and Specifications The design of the oil seal—such as its shape, size, and specific tolerances—also influences its price. Custom-designed seals tailored for particular applications or operating conditions tend to be more costly than standardized products. Furthermore, seals designed for high-performance applications, where the risk of failure must be minimized, will often require more advanced engineering, thus adding to their overall price.

3. Supply and Demand Dynamics Like any commodity, the price of hydraulic oil seals is subject to the laws of supply and demand. During periods of high industrial activity, the demand for hydraulic components, including oil seals, often rises sharply, potentially driving up prices. Conversely, economic downturns may see a reduction in hydraulic oil seal prices due to diminished demand.

4. Manufacturing Processes The method used in the production of hydraulic oil seals—from compression molding to injection molding—can also impact cost. Techniques that require more sophisticated equipment or more labor-intensive processes tend to generate higher prices. Additionally, automation in manufacturing can lead to cost savings, potentially reflecting in lower prices for the end consumer.

hydraulic oil seal price

5. Brand and Quality Assurance Established brands with a reputation for quality often charge a premium for their products. These manufacturers typically provide guarantees, certifications, and reliability testing, which can justify a higher price point. Investing in a higher-quality seal may result in lower overall costs through reduced maintenance and improved system reliability.

Market Trends

As industries innovate and evolve, so do the designs and materials used in hydraulic oil seals. Companies are increasingly investing in research and development to produce seals that offer greater longevity and performance. Advancements in material science are leading to the emergence of new seal compounds that can withstand extreme operating conditions, thus enhancing their practicality.

Additionally, sustainability is becoming a significant consideration in manufacturing processes. Consumer preferences for eco-friendly products may influence manufacturers to adopt more sustainable materials and processes, potentially affecting pricing structures.

Conclusion

In conclusion, the price of hydraulic oil seals is influenced by a multitude of factors, including material composition, design specifications, supply and demand, manufacturing processes, and brand reputation. Businesses must consider these aspects when purchasing hydraulic oil seals to ensure they select products that balance performance, cost, and reliability. As the market continues to innovate, staying informed about trends and advancements will aid companies in making well-informed decisions regarding their hydraulic system needs. Investing in high-quality hydraulic oil seals can lead to long-term savings through enhanced performance and durability, making it a critical consideration for any business reliant on hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories