2 сар . 10, 2025 10:41 Back to list

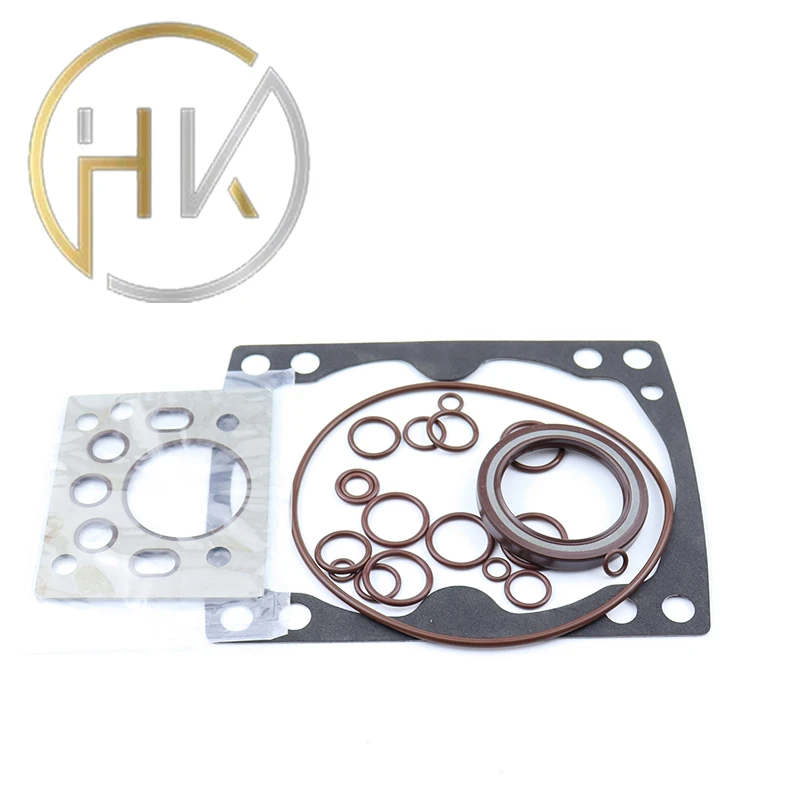

cross cylinder seal kit

Best practices suggest routine inspections and replacements of seal kits to preemptively manage wear and tear. Neglecting this can lead to catastrophic system failures, resulting in costly downtime and potential safety hazards. Maintenance schedules should be adhered to strictly, and any signs of wear, such as cracking or sustained deformation, should prompt immediate replacement of the seals. Real-world experiences emphasize the importance of a methodical approach to maintenance. In sectors like offshore drilling, where equipment failure can lead to environmental disasters, the emphasis on high-quality seal kits cannot be understated. Professionals in these industries often share their experiences, underscoring the prudence of investing in superior quality kits. While the initial cost may be higher, the long-term benefits of reduced failures and extended equipment lifespan are evident. This not only ensures uninterrupted operations but also enhances overall productivity. Choosing the right cross cylinder seal kit is a strategic decision that impacts the entire operational framework of hydraulic systems. By prioritizing quality, expertise, and reliability, operators can safeguard their equipment while optimizing performance. This informed approach not only demonstrates expertise but also fosters trust in the seamless function of essential industrial systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories