2 сар . 14, 2025 12:38 Back to list

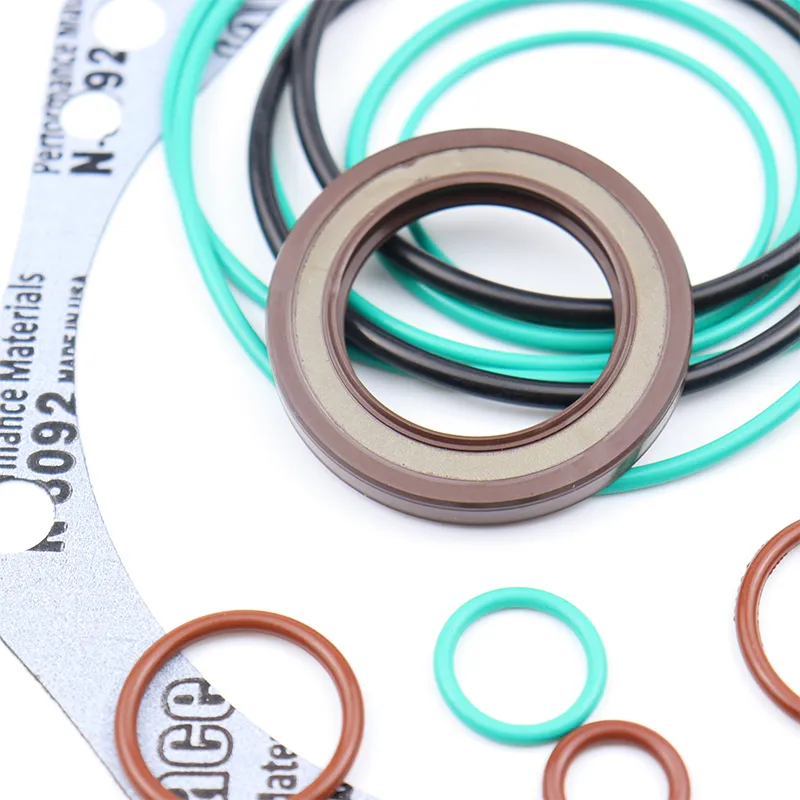

55 80 10 oil seal

Experience in the field shows recurring success in extending machinery life and minimizing unplanned downtime, thanks to the consistent performance of the 55 80 10 oil seal. Experts frequently attest to the reduction in maintenance costs when this seal is implemented, highlighting its role in sustaining operational efficiency. By preventing oil leaks and contamination, it ensures machinery components remain lubricated and free from debris, ultimately promoting equipment longevity. A frequent observation by industry veterans is that the precision with which these seals are manufactured is crucial to their effectiveness. The dimensions of the 55 80 10 oil seal must be exact to create the perfect seal, underscoring the importance of sourcing these components from reputable suppliers. Dependable manufacturers provide not only products vetted for quality and durability but also compliance with industry standards, bolstering trustworthiness. In a modern industrial landscape where sustainability and efficiency are paramount, the 55 80 10 oil seal aligns perfectly with the goals of reducing waste and conserving resources. Its contribution to preventing leaks and conserving lubricants adds an environmental advantage, appealing to companies aiming to minimize their carbon footprint. Ultimately, choosing the correct oil seal affects not only machinery effectiveness but also safety and economic performance. The 55 80 10 oil seal is a testament to engineering excellence, with its proven track record in demanding environments making it a trusted choice for industries seeking high-performing and reliable sealing solutions. In conclusion, the 55 80 10 oil seal may appear to be a small component, but its impact on machinery efficiency, reliability, and operational cost cannot be overstated. Its integration into industrial systems represents a commitment to embracing technology that maximizes functionality and minimizes risk. For professionals in the industry, prioritizing such premium components embodies strategic foresight that protects both machinery investments and the integrity of operational processes.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories