നവം . 22, 2024 18:51 Back to list

rubber wiper seal

Understanding Rubber Wiper Seals Importance and Applications

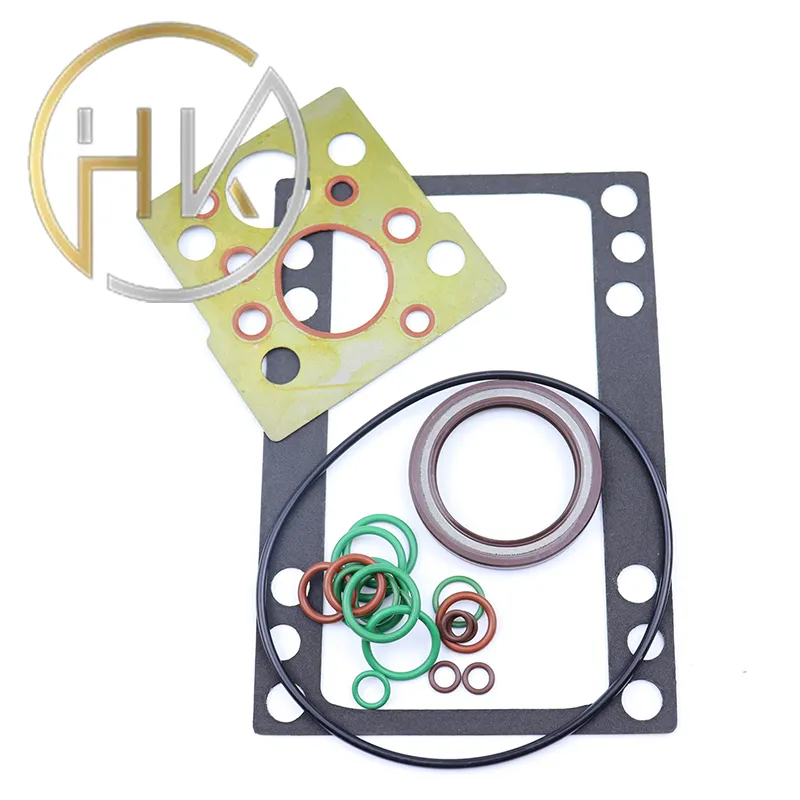

Rubber wiper seals are essential components in various mechanical systems, providing crucial sealing functions that help maintain the integrity and efficiency of machinery. These seals are primarily designed to prevent the ingress of dirt, dust, and moisture while retaining internal lubricants and fluids. They play a vital role in numerous applications, including automotive, industrial machinery, and household appliances.

One of the main advantages of rubber wiper seals is their flexibility. Made from high-quality rubber compounds, these seals can accommodate dynamic movements and varying temperatures, ensuring a reliable seal even under challenging conditions. Typically, the seals feature a lip that wipes away contaminants as the moving parts come into contact, which effectively reduces wear and tear.

In automotive applications, rubber wiper seals are commonly found in components like windshield wipers and engine systems. For example, windshield wipers utilize these seals to ensure that water and debris are effectively removed from the glass surface, providing clear visibility for drivers. In engines, rubber wiper seals help prevent leaks in components like crankshafts and camshafts, safeguarding against potential damage caused by oil loss.

rubber wiper seal

In industrial settings, rubber wiper seals are essential for machinery operating in harsh environments

. They often protect hydraulic cylinders and pneumatic systems, ensuring that dirt and moisture do not compromise the fluid systems. This protection is crucial for the longevity and effective performance of machinery, as contaminants can lead to significant operational failures or costly repairs.Another significant aspect of rubber wiper seals is their customization. Manufacturers can produce seals in various shapes, sizes, and rubber compounds to meet specific requirements for different applications. For instance, seals made from EPDM (ethylene propylene diene monomer) rubber are particularly effective in outdoor applications due to their excellent resistance to UV rays and ozone. On the other hand, Nitrile rubber seals are favored in environments where they will be exposed to oils and fuels.

The maintenance and replacement of rubber wiper seals are also vital for optimal performance. Regular inspections can help identify signs of wear or damage, allowing for timely replacements that prevent more extensive issues. Neglecting these components can lead to increased friction, higher energy consumption, and ultimately, system failures.

In conclusion, rubber wiper seals are critical in various industries, serving as a barrier against contaminants and preserving the functionality of mechanical systems. Their flexibility, durability, and ability to be tailored for specific applications make them indispensable in both consumer products and heavy machinery. Investing in quality rubber wiper seals and ensuring their proper maintenance is crucial for the longevity and efficiency of the systems they protect. Whether in automobiles, industrial machines, or household appliances, these seals play a pivotal role in enhancing performance and operational reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories