ജനു . 22, 2025 03:31 Back to list

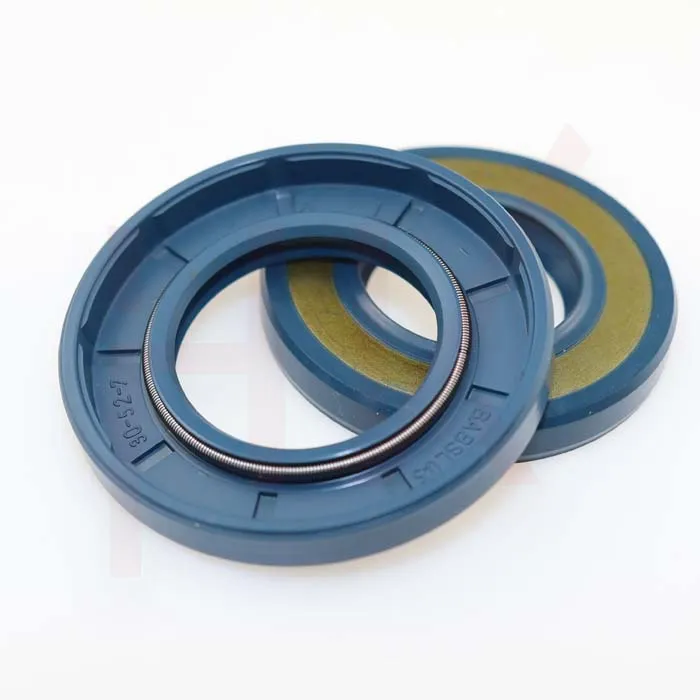

wiper seals

From an engineering perspective, the expertise required to select the appropriate PU wiper seal cannot be overstated. Decisions hinge not only on the seal’s material properties but also on factors such as operating temperature, pressure conditions, and the type of hydraulic fluid used. Engaging with a knowledgeable supplier ensures the deployment of a seal that harmonizes perfectly with operational parameters, preventing potential failures stemming from misfits or material degradation. In terms of authority and trustworthiness, PU wiper seals have gained acknowledgment within industry standards. Reputable manufacturers subject these seals to rigorous testing and quality assurance processes, certifying that every seal meets stringent performance criteria. Such standards are instrumental in fostering trust among end-users, guaranteeing that the seal’s performance will align with the promises made by manufacturers. End-users sharing their experiences reiterate the crucial impact of PU wiper seals on system effectiveness. Testimonials often cite the prolonged service intervals and significant cost savings achieved by incorporating these seals into their equipment. These firsthand accounts provide invaluable insights, reinforcing the critical role PU wiper seals play in promoting efficient and sustainable operations. Ultimately, the adoption of PU wiper seals transcends a mere component addition; it represents a strategic enhancement of operational integrity. For industries that hinge on the flawless performance of hydraulic and pneumatic systems, such a decision echoes profound implications reduced maintenance costs, minimized downtime, and a heightened return on investment. These seals, while perhaps understated in their presence, emerge as pivotal elements that drive the operational excellence of today's industrial machinery.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories