സെപ് . 01, 2024 15:59 Back to list

pu wiper seal

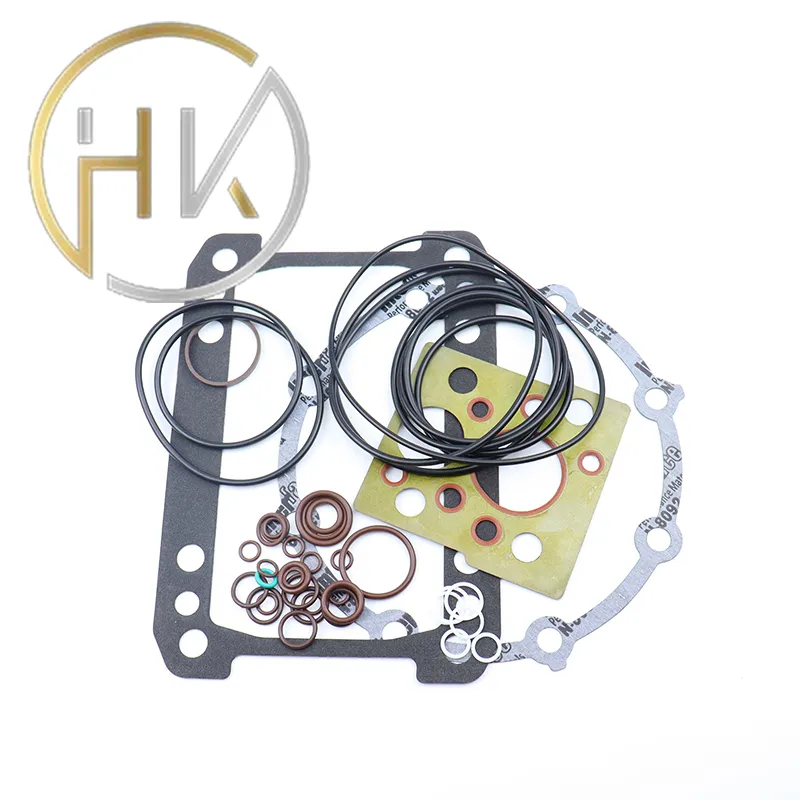

Understanding PU Wiper Seals A Comprehensive Overview

In today's industrial landscape, the demand for efficient sealing solutions has grown exponentially. One component that has gained significant traction in various applications is the PU wiper seal. These seals, made from polyurethane (PU), are designed to provide effective sealing solutions in a wide range of environments, including hydraulic systems, pneumatic equipment, and automotive applications. This article delves into the characteristics, advantages, applications, and maintenance of PU wiper seals.

Characteristics of PU Wiper Seals

PU wiper seals are characterized by their unique composition and structure. Polyurethane is a versatile polymer renowned for its excellent wear resistance, durability, and flexibility. These seals typically feature a robust design that allows them to withstand high pressures and dynamic movements, making them ideal for environments where traditional elastomer seals may fail.

The design of PU wiper seals often includes a specially shaped lip that effectively removes contaminants and debris from the rod or shaft's surface as it moves. This ensures that the internal components of hydraulic or pneumatic systems remain clean, thereby extending their lifespan and maintaining optimal performance. The seals are engineered to fit snugly, creating a barrier that prevents external contaminants from entering while allowing fluids to flow freely.

Advantages of PU Wiper Seals

One of the primary advantages of PU wiper seals is their outstanding resistance to abrasion and extrusion. This makes them particularly well-suited for applications involving movement and frequent contact with other surfaces. Additionally, PU seals exhibit excellent chemical resistance, allowing them to maintain integrity even when exposed to oils, fluids, and various industrial chemicals.

Another significant benefit is their temperature tolerance. PU wiper seals can typically operate in a wide temperature range, making them suitable for both cold and hot environments. This versatility enables their use in diverse applications, from agricultural machinery to aerospace components.

pu wiper seal

Furthermore, PU wiper seals are cost-effective solutions. While the initial investment may be slightly higher than that of conventional rubber seals, their durability and longevity lead to lower maintenance costs and reduced downtime, ultimately resulting in better overall value.

Applications of PU Wiper Seals

The versatility of PU wiper seals allows for a broad range of applications across various industries. In the automotive sector, they are commonly used in hydraulic cylinders, shock absorbers, and steering mechanisms. In industrial settings, they can be found in forklifts, construction equipment, and manufacturing machinery.

Additionally, PU wiper seals play a crucial role in the field of aerospace, where precision and reliability are paramount. They are utilized in landing gear systems and hydraulic control systems, where they effectively minimize the risk of fluid leaks and contamination.

Maintenance and Considerations

To maximize the lifespan and effectiveness of PU wiper seals, proper maintenance is essential. Regular inspections should be conducted to identify any signs of wear or damage. Ensuring that the installation is performed correctly is also vital, as improper fitting can lead to premature failure.

In conclusion, PU wiper seals are an integral component in many mechanical processes, offering durability, versatility, and efficiency. As technology continues to evolve, the development and application of these seals will likely expand, further enhancing their importance in various industries. By understanding their characteristics and advantages, engineers and maintenance professionals can make informed decisions to enhance equipment reliability and performance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories