ഫെബ്രു . 14, 2025 17:00 Back to list

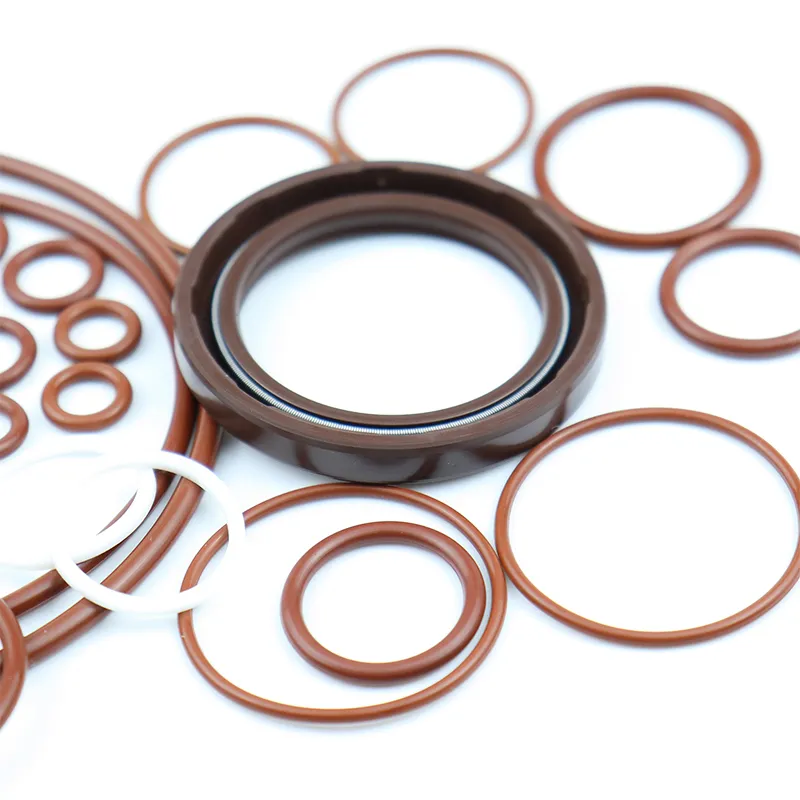

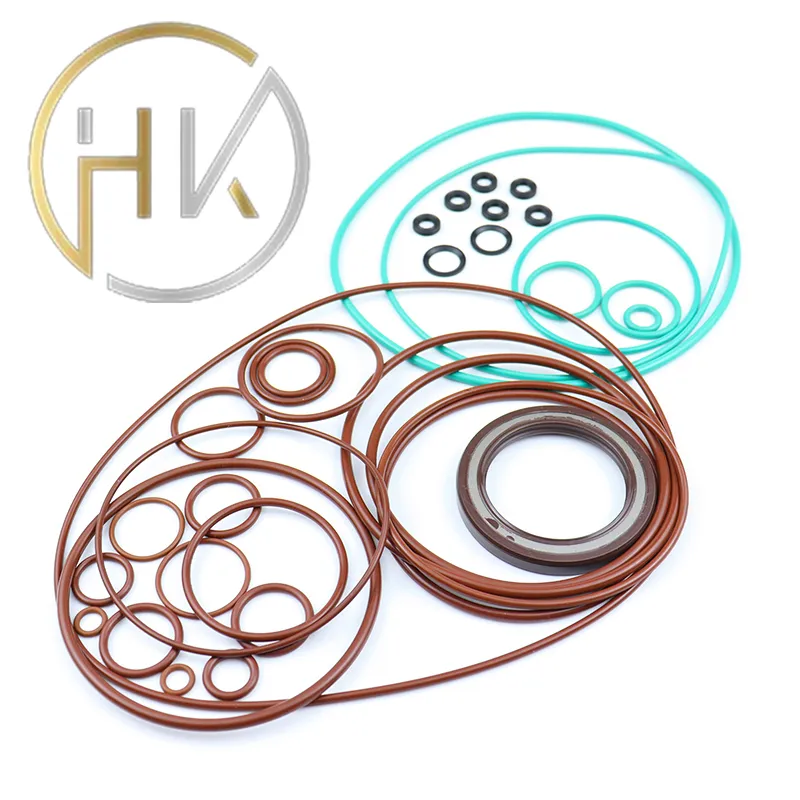

oil seals

Authoritative insights into oil seal application highlight the profound impact of selecting the right seal on operational efficiency and maintenance costs. Historically, instances of seal failure have led to costly downtimes, production losses, and, frequently, machinery damage. Thus, industry reports and case studies consistently emphasize rigorous testing and dynamic performance evaluation to adhere to safety standards and regulatory compliances. Companies that have pioneered advancements in seal technology invest heavily in research and development, thereby upholding their status as leaders in engineering innovation and operational excellence. Trust in industrial oil seals is built through consistent performance and proven durability across demanding environments. The track record of top-performing seals is established through extensive field testing and feedback from end-users. This empirical evidence of reliability ensures that manufacturers and end-users alike can have confidence in their operational machinery. The selection process for these seals is often guided by both independent assessments and endorsements from established industry bodies, further enhancing their credibility and acceptance. In conclusion, industrial oil seals may appear to be simple components within complex machinery, yet their role is profoundly transformative. As unsung heroes of industrial efficacy, they provide essential sealing solutions that protect and enhance machine performance. A comprehensive understanding of their construction, capabilities, and relevance not only reinforces their importance but assures their continued evolution in tandem with industrial innovation. As industries progress, the demand for reliable, customized, and high-performance seals will inevitably drive further developments, ensuring that they remain at the heart of mechanical resilience and efficiency.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories