ഫെബ്രു . 11, 2025 05:21 Back to list

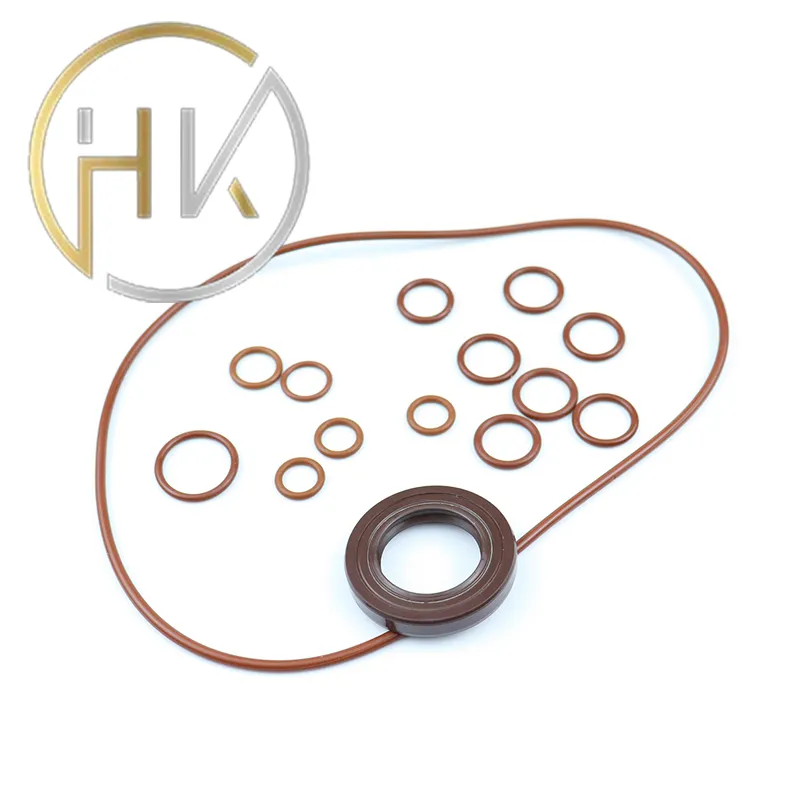

wiper seals

Furthermore, collaborating with trusted providers for hydraulic wiper parts adds another layer of reliability to maintaining hydraulic systems. These providers, often with decades of manufacturing experience, bring an unparalleled level of trustworthiness to their products. They offer detailed guidance on choosing the appropriate wiper based on specific system requirements, environmental conditions, and other factors, ensuring that each choice aligns perfectly with operational demands. In the rapidly advancing field of hydraulic technology, innovations in wiper design continue to emerge. Research and development efforts focus on enhancing the sealing capabilities, material strength, and environmental adaptability of hydraulic wipers. The future promises even more robust solutions that will further streamline maintenance processes and extend the life of hydraulic systems. Engaging with updates and innovations in this field positions businesses to remain at the forefront of industrial advancements, seizing competitive advantages through enhanced efficiency and reduced costs. For anyone involved in the manufacturing, maintenance, or operation of hydraulic systems, understanding and valuing the role of hydraulic wipers is synonymous with expertise in the field. The knowledge shared by industry leaders and the practical insights gained through years of experience converge to emphasize a simple truth hydraulic wipers are indispensable in protecting investments in hydraulic technology. In conclusion, hydraulic wipers, though a small component, wield significant influence over the performance and durability of hydraulic systems. Their role in combating contamination is crucial for optimizing performance and reducing maintenance costs. By prioritizing the selection and upkeep of high-quality wipers, businesses safeguard their operations, ensuring longevity and efficiency across their hydraulic infrastructures.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories