ഫെബ്രു . 05, 2025 04:22 Back to list

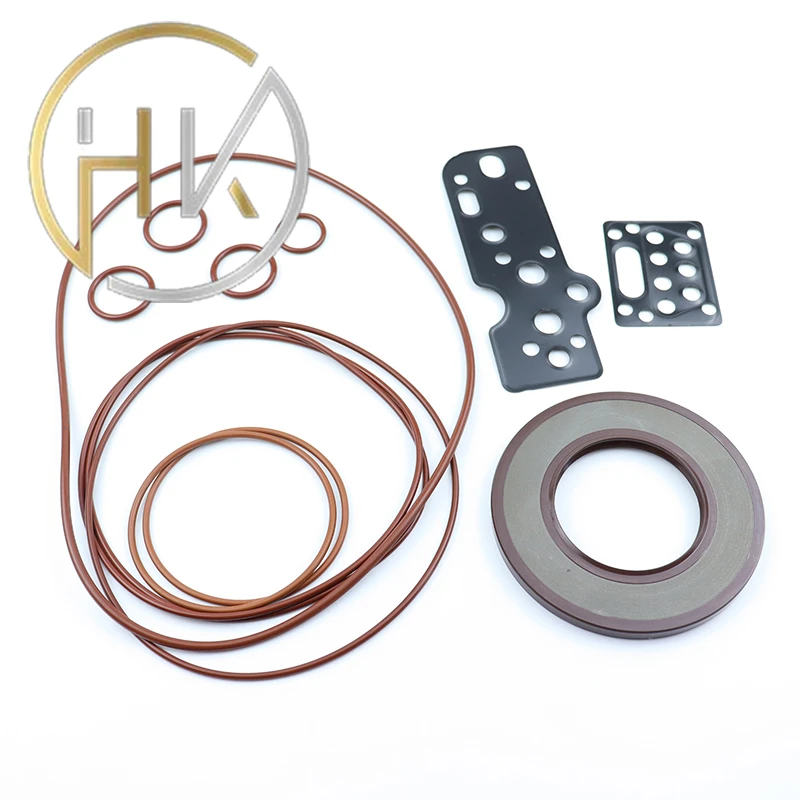

dkb seal

From an expertise standpoint, it's essential to address the critical aspects of proper installation and maintenance of hydraulic dust seals. Installation should be carried out by trained professionals who understand the specific requirements of the machinery in question. Incorrect installation can compromise the seal's effectiveness, leading to potential system vulnerabilities. It is advisable that routine inspections be incorporated into maintenance schedules to check for signs of wear, hardening, or cracks in the seals, which can inform proactive replacement before they fail. Authoritative voices in the industry often highlight the advancements in seal technologies that have introduced innovative designs such as dual-lip configurations, which offer superior sealing capabilities compared to traditional single-lip designs. The dual-lip design provides an additional layer of protection, ensuring that even if one lip fails, the second maintains the seal, thereby enhancing reliability. Staying informed about such advancements can be advantageous for industry stakeholders aiming to maintain a competitive edge. Trustworthiness in any component used in industrial applications is built upon proven track performance. Hydraulic dust seals from reputable manufacturers undergo rigorous testing and quality assurance processes to ensure they meet industry standards. It is crucial for procurement specialists to source seals from manufacturers with a track record of quality, backed by relevant certifications. Opting for such suppliers not only guarantees product performance but also reinforces trust in the machinery's overall reliability. In conclusion, hydraulic dust seals may seem like a minor component in the grand scheme of industrial machinery; however, their impact is significant. They represent a critical line of defense against contamination, directly influencing the efficiency, maintenance cost, and lifespan of hydraulic systems. By leveraging the expertise and innovations available in dust seal technologies, industries can achieve substantial operational benefits and secure their investment in high-value equipment. Whether you're in procurement, engineering, or maintenance, recognizing the importance of high-quality hydraulic dust seals can provide a decisive advantage in achieving system reliability and operational excellence.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories