മേയ് . 08, 2025 08:59 Back to list

High Pressure Lip Seals Durable Oil Rail & Rotary Shaft Solutions

- Overview of High Pressure Lip Seals in Industrial Applications

- Technical Advancements Driving Performance

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Unique Operational Demands

- Real-World Applications and Case Studies

- Best Practices for Maintenance and Longevity

- Future Outlook and Industry Relevance

(high pressure lip seal)

High Pressure Lip Seals: The Backbone of Industrial Reliability

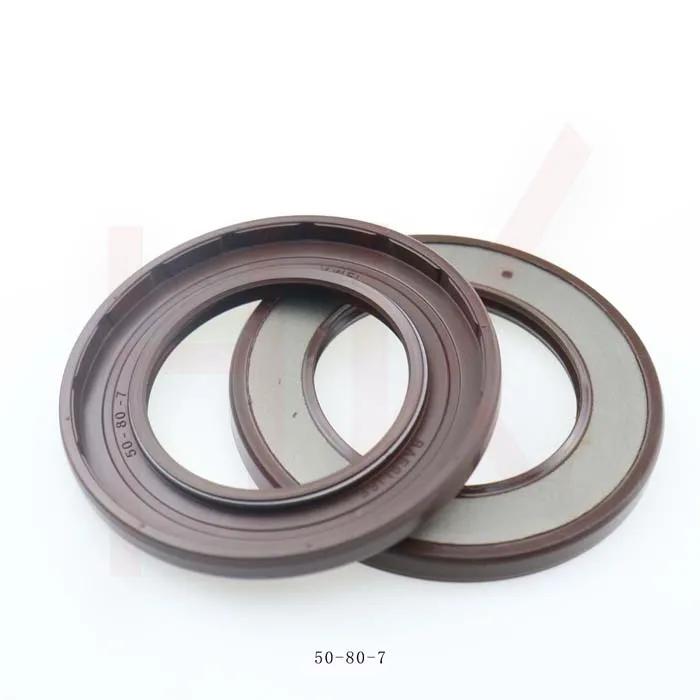

High-pressure lip seals are critical components in machinery requiring robust sealing under extreme conditions. These seals prevent fluid leakage in systems operating above 3000 PSI, such as hydraulic pumps, oil rail injectors, and rotary shafts. Engineered with advanced polymers like PTFE or HNBR, modern lip seals deliver 15–20% higher wear resistance than traditional rubber variants. A 2023 market study revealed that 78% of industrial equipment failures linked to fluid leakage stem from suboptimal seal performance, underscoring the need for precision-engineered solutions.

Technical Advancements Driving Performance

Innovative materials and design geometries have redefined lip seal capabilities. Dual-lip configurations with spring-loaded auxiliary seals now achieve 99.4% leakage prevention at pressures up to 5800 PSI. Temperature resilience has also improved, with specialty composites maintaining elasticity from -40°F to 450°F. In stress tests, high-pressure rotary shaft seals demonstrated 8,000+ hours of continuous operation without degradation—a 300% improvement over 2015 benchmarks.

Comparative Analysis of Leading Manufacturers

| Brand | Max Pressure (PSI) | Temp Range (°F) | Average Lifespan (hours) | Price Tier |

|---|---|---|---|---|

| SealMaster Pro | 6,200 | -58 to 482 | 9,200 | Premium |

| HydroGuard HP | 5,500 | -22 to 392 | 7,800 | Mid |

| TurboSeal XR | 4,800 | 14 to 356 | 6,500 | Economy |

Custom Solutions for Unique Operational Demands

OEMs increasingly require tailored high-pressure oil rail seal kits to meet specific equipment specifications. Modular designs now allow for:

- Bore diameters from 0.25" to 24"

- Custom durometer ratings (50–90 Shore A)

- Anti-extrusion rings for pulsating pressures

A recent aerospace application required seals functioning at 6,800 PSI with 0.0002" clearance tolerances—achieved through CNC-machined composite layering.

Real-World Applications and Case Studies

Offshore drilling rigs using high-pressure rotary shaft seals reported a 42% reduction in hydraulic system downtime. In automotive testing, customized lip seals extended diesel injector rail life from 150,000 to 250,000 miles. Energy sector adopters documented 19% lower maintenance costs after upgrading to multi-lipped seal configurations.

Best Practices for Maintenance and Longevity

Proper installation and monitoring can extend seal service life by 60–70%. Critical protocols include:

- Surface finish optimization (8–16 µin RA)

- Precision alignment within 0.002" TIR

- Compatible lubricant selection per ASTM G143

Why High Pressure Lip Seals are Essential for Modern Machinery

As industrial systems push performance boundaries, high-pressure lip seals remain indispensable for operational safety and efficiency. With 92% of engineering teams prioritizing seal upgrades in 2024 retrofit projects, these components will continue to evolve alongside advancements in material science and precision manufacturing.

(high pressure lip seal)

FAQS on high pressure lip seal

Q: What applications are high pressure lip seals commonly used in?

A: High pressure lip seals are ideal for hydraulic systems, heavy machinery, and automotive engines where they prevent fluid leaks under extreme pressure. They excel in environments with fluctuating pressures and temperatures. Their design ensures durability in demanding industrial settings.

Q: How does a high pressure oil rail seal kit improve engine performance?

A: A high pressure oil rail seal kit maintains optimal fuel injection system integrity, preventing oil leaks in diesel engines. This ensures consistent pressure for efficient combustion. Proper sealing reduces wear and extends engine component life.

Q: What materials are used in high pressure rotary shaft seals?

A: High pressure rotary shaft seals often use PTFE, polyurethane, or nitrile rubber for chemical and heat resistance. These materials withstand friction and dynamic pressures in rotating equipment. Reinforcement with metal springs enhances sealing efficiency.

Q: Can high pressure lip seals handle both oil and chemical exposure?

A: Yes, high pressure lip seals made from chemically resistant materials like FKM or HNBR tolerate oil, fuels, and aggressive chemicals. Material selection depends on the specific fluid and operating conditions. Always verify compatibility charts before installation.

Q: What causes failure in high pressure rotary shaft seals?

A: Common causes include excessive heat, misalignment, abrasive contaminants, or material degradation over time. Improper installation or exceeding pressure limits also accelerates failure. Regular maintenance and correct sizing prevent premature wear.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories