നവം . 06, 2024 22:03 Back to list

gear box seal kit

Understanding Gearbox Seal Kits Importance and Maintenance

A gearbox is a crucial component in many machines and vehicles, playing a vital role in transmitting power and torque. To ensure its optimal operation, one of the essential elements is the gearbox seal kit. This kit guarantees that the gearbox functions efficiently while preventing the leakage of lubricants, which can lead to significant damage if not addressed properly.

What is a Gearbox Seal Kit?

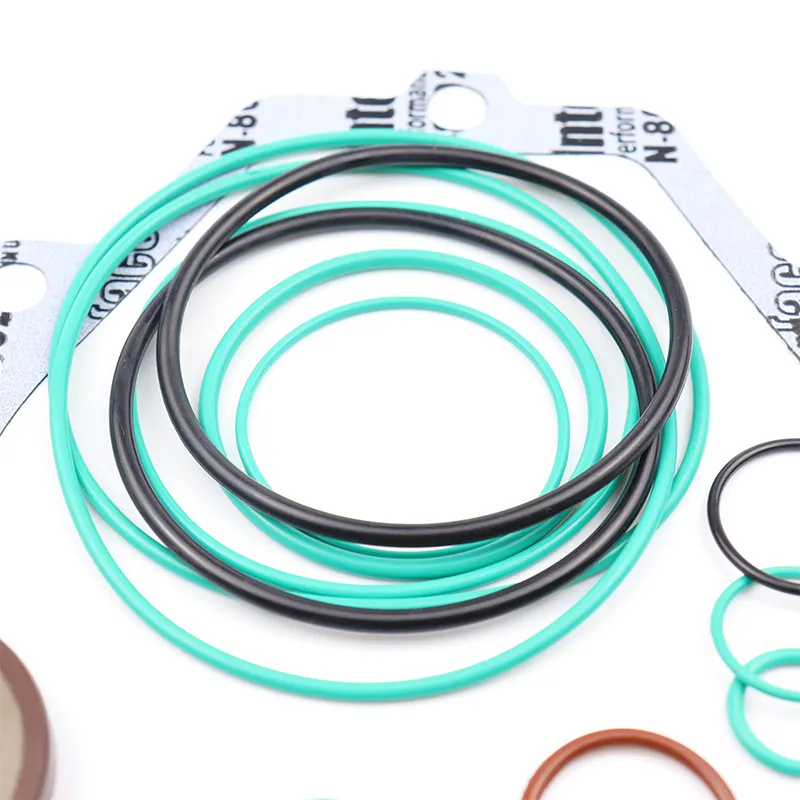

A gearbox seal kit typically contains various types of seals and gaskets designed to fit specific gearbox models. These components are responsible for creating a tight barrier that keeps lubricant in the gearbox and contaminants out. The primary seals in the kit include lip seals, O-rings, and various gasket styles, each serving its unique function based on the design of the gearbox.

Importance of Gearbox Seal Kits

1. Prevention of Leaks One of the key functions of the seals is to prevent oil leaks. A leak can lead to inadequate lubrication, resulting in overheating and potential component failure. By using a seal kit, you can ensure that your gearbox retains its lubricants, extending its lifespan.

2. Protection Against Contaminants In addition to keeping lubricants in, seals also protect the internal components from dirt, dust, and moisture. This protective feature is crucial as contaminants can cause wear and tear, leading to more frequent repairs and increased operational costs.

3. Enhanced Performance Seals play a critical role in maintaining the efficiency of the gearbox. Proper sealing can optimize the pressure within the gearbox, ensuring that it operates smoothly under various conditions. This enhancement in performance translates to better power delivery and overall efficiency of the machine or vehicle.

gear box seal kit

Maintenance Tips

To ensure that your gearbox and its seal kit function effectively, regular maintenance is essential. Here are some useful tips

- Regular Inspections Periodically check the seals for wear and tear. Look for signs of leaking fluid or cracks in the seal material, which could indicate that replacement is necessary.

- Use Quality Products When replacing seals, always opt for high-quality parts that are compatible with your gearbox model. Using substandard products may lead to premature failure and increased maintenance costs.

- Follow Manufacturer Guidelines Adhere to the manufacturer's recommendations regarding maintenance schedules and fluid types. This practice ensures that the gearbox operates under optimal conditions and that the seals remain effective.

- Installation Matters Proper installation of seal kits is crucial. Misalignment or incorrect installation can lead to premature failure. Take your time during the installation process, and don’t hesitate to consult a professional if necessary.

Conclusion

In summary, a gearbox seal kit is an indispensable part of any machinery containing a gearbox. By ensuring proper sealing, you not only safeguard the internal components from damage but also enhance the overall performance of the gearbox. Regular maintenance and timely replacement of seals can prevent costly repairs and extend the life of your equipment. Investing in a quality gearbox seal kit is a step towards ensuring the longevity and efficiency of your machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories