ഡിസം . 17, 2024 09:28 Back to list

Excavator Boom Cylinder Seal Change Guide for Optimal Performance and Longevity

Excavator Boom Cylinder Seal Replacement A Comprehensive Guide

Excavators are crucial workhorses in construction, mining, and other heavy-duty industries. One of the key components of an excavator's hydraulic system is the boom cylinder, which is responsible for lifting and lowering the boom. To ensure optimal function and longevity, regular maintenance is essential, including timely seal replacement. This article will walk you through the process of replacing the seals in an excavator boom cylinder, covering the tools needed, the steps involved, and important tips to keep in mind.

Importance of Seal Replacement

The seals in the boom cylinder play a critical role in maintaining hydraulic pressure. Over time, seals can wear out due to friction, exposure to fluids, and environmental factors. A worn seal can lead to hydraulic fluid leaks, decreased efficiency, and potential damage to other components of the excavator. Replacing seals on a regular basis not only improves performance but also extends the lifespan of the boom cylinder and the excavator overall.

Tools and Materials Needed

Before you embark on the seal replacement process, make sure you have the following tools and materials

1. Basic Hand Tools Wrenches, screwdrivers, and pliers. 2. Hydraulic Jack To safely lift the excavator for access to the boom cylinder. 3. Seal Kit Specific to the model of your excavator, including new seals and O-rings. 4. Clean Cloths For cleanup and to avoid contamination. 5. Hydraulic Fluid To top off the system after replacement. 6. Retaining Ring Pliers If applicable, for removing retaining rings.

Step-by-Step Process

1. Safety First Before you begin any maintenance work on your excavator, ensure the machine is on stable ground and turned off. Use safety glasses and gloves to protect yourself from hydraulic fluid and debris.

2. Lift the Excavator Use a hydraulic jack to lift the excavator safely. Ensure that it is secure and stable before proceeding.

excavator boom cylinder seal replacement

3. Remove the Boom Cylinder Disconnect the hydraulic lines from the boom cylinder. Use wrenches to loosen the fittings, and be prepared for some hydraulic fluid to leak out. Once the lines are disconnected, remove the cylinder from the boom assembly.

4. Disassemble the Cylinder On a clean surface, carefully disassemble the cylinder. Remove the end caps or retaining rings using the appropriate tools. Take note of the order in which parts are removed, as you will need to reassemble them in the same order.

5. Inspect the Components Once the cylinder is disassembled, inspect the internal components for signs of wear or damage. Check the cylinder walls for scratches and the pistons for any noticeable damage.

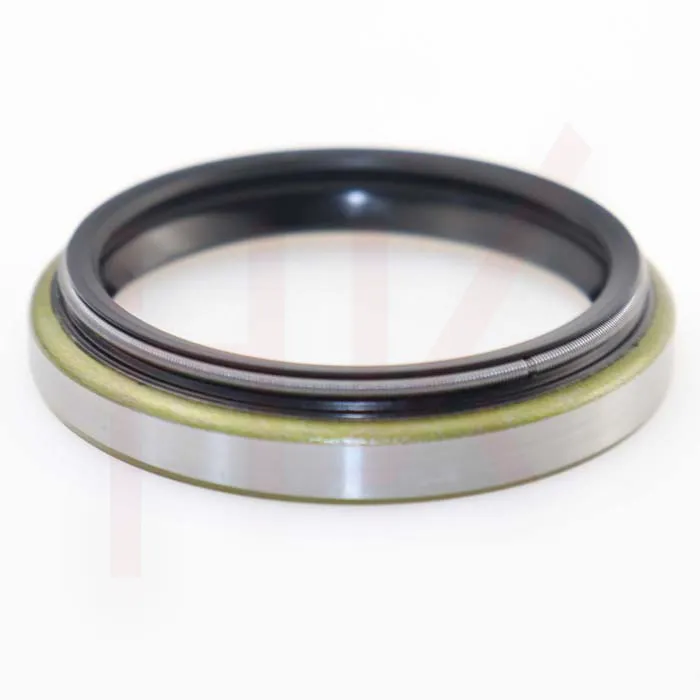

6. Replace the Seals Remove the old seals from the cylinder. Clean the grooves thoroughly to ensure a proper fit for the new seals. Install the new seals from the seal kit, ensuring they sit correctly and are aligned evenly.

7. Reassemble the Cylinder Carefully reassemble the boom cylinder in the reverse order of disassembly. Make sure all components are secure and properly aligned.

8. Reinstall the Cylinder Once the boom cylinder is reassembled, reinstall it on the excavator. Reconnect the hydraulic lines, ensuring there are no leaks at the fittings.

9. Refill Hydraulic Fluid Check the hydraulic fluid levels and top off if necessary. This step is crucial for ensuring smooth operation.

10. Test the Boom Start the excavator and test the boom's operation. Check for any leaks around the newly replaced seals and observe for any irregularities in movement.

Conclusion

Replacing the seals in an excavator's boom cylinder is a critical maintenance task that can greatly enhance the machine's performance and longevity. By following this comprehensive guide and adhering to safety protocols, you can successfully perform seal replacement and ensure your excavator remains a reliable asset on the job site. Regular maintenance, including timely seal checks and replacements, is essential in preventing costly repairs and downtime, ultimately contributing to the productivity and efficiency of your operations.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories