ഡിസം . 02, 2024 07:36 Back to list

Strategies for Effective Dust Seal Implementation in Industrial Environments and Equipment

Understanding Dust Seals Importance and Applications

Dust seals, an essential component of various mechanical systems, play a crucial role in protecting equipment and extending the lifespan of machinery. Their primary function is to prevent dust, dirt, and other contaminants from entering critical areas of machines and equipment, thereby maintaining operational efficiency and reliability. This article explores the importance of dust seals, their applications, and key considerations for their selection and maintenance.

The Importance of Dust Seals

Dust seals provide a protective barrier that keeps harmful particles at bay. In many industrial environments, equipment is exposed to dust and debris, which can lead to premature wear and tear if not adequately controlled. Contaminants can infiltrate bearings, gears, and hydraulic systems, causing malfunctions, decreased efficiency, and ultimately higher maintenance costs. By employing dust seals, companies can mitigate these risks, ensuring smoother operations and reducing the frequency of repairs.

Furthermore, in applications where machinery operates in extreme conditions, such as construction sites or mining operations, the importance of dust seals becomes even more pronounced. The robust design of these seals is tailored to withstand harsh environments, promoting the smooth functioning of machines even under challenging circumstances. This durability not only preserves the integrity of the machinery but also enhances safety for operators and workers on-site.

Applications of Dust Seals

Dust seals are utilized across various industries, including automotive, aerospace, construction, and manufacturing. In the automotive sector, for example, dust seals are commonly found in wheel bearings, shock absorbers, and drive axles. They prevent dirt and moisture from entering critical components, which can significantly affect vehicle performance and safety.

In the manufacturing industry, dust seals are essential in machinery like conveyor systems, hydraulic systems, and packaging equipment. They ensure that moving parts are free from contaminants, thus maintaining product quality and operational efficiency. In aerospace applications, the reliability of dust seals is paramount, as contaminants can compromise safety and performance in flight systems.

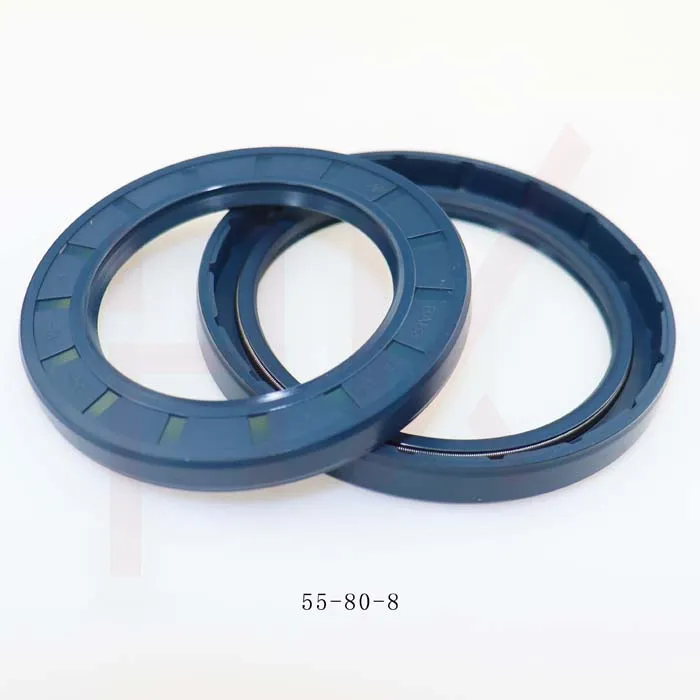

dust seal

Moreover, dust seals are not limited to heavy machinery or industrial applications. They are also found in everyday products such as household appliances, electronics, and fitness equipment. For instance, fitness machines often utilize dust seals to protect sensitive electronics from dust exposure, enhancing durability and performance.

Key Considerations for Selecting Dust Seals

When choosing dust seals for specific applications, several factors must be considered. First, the environmental conditions in which the equipment operates play a critical role in seal selection. Factors such as temperature extremes, exposure to chemicals, and the presence of abrasive materials will influence the type of seal material and design.

Second, the type of motion involved in the application—whether it be rotary or linear—dictates the design and functionality of the dust seal. Manufacturers must ensure that the selected seal can accommodate the specific motion while providing a secure barrier against contaminants.

Lastly, regular maintenance and inspection of dust seals are essential to ensure their effectiveness. Over time, seals can wear out or become damaged, leading to compromised protection. Implementing a routine maintenance schedule helps identify potential issues early, facilitating timely replacements and minimizing equipment downtimes.

Conclusion

In summary, dust seals are vital components that provide protection against dirt, dust, and other contaminants in various mechanical systems. Their role in enhancing efficiency, safety, and longevity of machinery cannot be overstated. With applications spanning several industries, the proper selection and maintenance of dust seals are crucial for optimizing equipment performance. By prioritizing these protective elements, businesses can ensure their machinery operates smoothly, ultimately leading to reduced costs and increased productivity. As technology continues to advance, the development of even more effective dust seals will likely become a focal point for engineers and manufacturers aiming to meet the demands of increasingly challenging environments.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories