നവം . 26, 2024 05:34 Back to list

Similar for Oil Seal Specifications and Applications in Industry

Understanding the Importance of the 20% 35% 7% Oil Seal in Industrial Applications

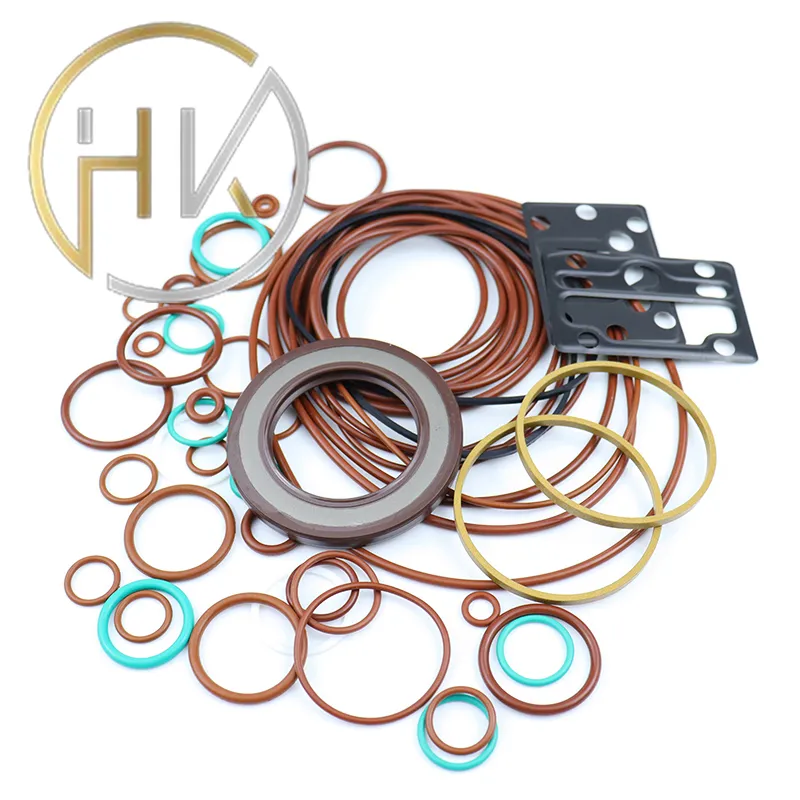

In the realm of engineering and manufacturing, the oil seal plays a pivotal role in preventing leaks and maintaining the integrity of machinery. Among various specifications and models of oil seals, the 20% 35% 7% oil seal stands out due to its unique characteristics and application benefits. This article explores the significance of this oil seal, its structure, and its relevance in industrial settings.

What is an Oil Seal?

An oil seal is a mechanical component designed to retain the lubrication oil in a system while simultaneously preventing the ingress of contaminants such as dirt and moisture. It usually consists of a rubber seal encased in a metal housing, providing a secure fit around rotating shafts. Oil seals are critical in numerous applications, especially in engines, transmissions, and hydraulic systems.

The 20% 35% 7% Specification

The 20% 35% 7% designation pertains to specific parameters that define this oil seal's dimensions and material composition. These percentages can refer to the hardness and thickness of the seal material, as well as the gap this seal can cover. Understanding these parameters is essential for engineers and technicians when selecting the right oil seal for a particular application.

1. Material Composition The material of the oil seal significantly impacts its performance. In many cases, seals are made from elastomers like nitrile rubber or fluorocarbon, which provide excellent resistance to oil and high temperatures. The 20% in the designation might imply a specific blend of these materials that enhance durability and functionality.

2. Hardness and Flexibility The 35% in this context could refer to the durometer hardness of the seal material. A hardness rating of 35 Shore A indicates that the seal is relatively soft, allowing it to conform better to uneven surfaces. This flexibility ensures a tighter seal, reducing the chances of leakage.

3. Thickness and Gap Coverage The 7% could indicate the thickness of the oil seal or the range it can accommodate in terms of shaft dimensions. A seal with an appropriate thickness is necessary to withstand operational pressures while ensuring minimal friction during rotation.

20 35 7 oil seal

Applications of the 20% 35% 7% Oil Seal

The 20% 35% 7% oil seal is employed across various industries, including automotive, aerospace, and manufacturing. In automotive engines, for instance, oil seals prevent oil from leaking out of the crankshaft and camshaft areas, which is critical for maintaining lubrication and preventing engine wear. In aerospace applications, where reliability is paramount, these seals are essential in turbine engines, ensuring that lubricants do not escape under high-speed conditions.

Benefits of Using the 20% 35% 7% Oil Seal

1. Leak Prevention By creating a robust barrier against fluid escape, these oil seals enhance the longevity and efficiency of machinery. 2. Reduced Maintenance Implementing quality oil seals reduces the frequency of maintenance checks and repairs, leading to cost savings over time.

3. Improved Performance By keeping contaminants out and ensuring the lubricant stays where it is needed, the overall performance and efficiency of machinery increase significantly.

4. Versatility The design of the 20% 35% 7% oil seal allows it to be used in a variety of applications, making it a versatile choice for many industrial settings.

Conclusion

The 20% 35% 7% oil seal exemplifies the meticulous engineering required in industrial applications. Through its specific material composition, hardness, and thickness, it provides essential benefits that enhance machine performance and reliability. Understanding and implementing the right oil seal is crucial for anyone involved in maintenance and manufacturing, ensuring that systems run smoothly and efficiently over time. Whether in automotive engines or complex manufacturing machinery, the significance of such a seemingly simple component cannot be overstated.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories