Ное . 14, 2024 03:44 Back to list

gear pump seal kit

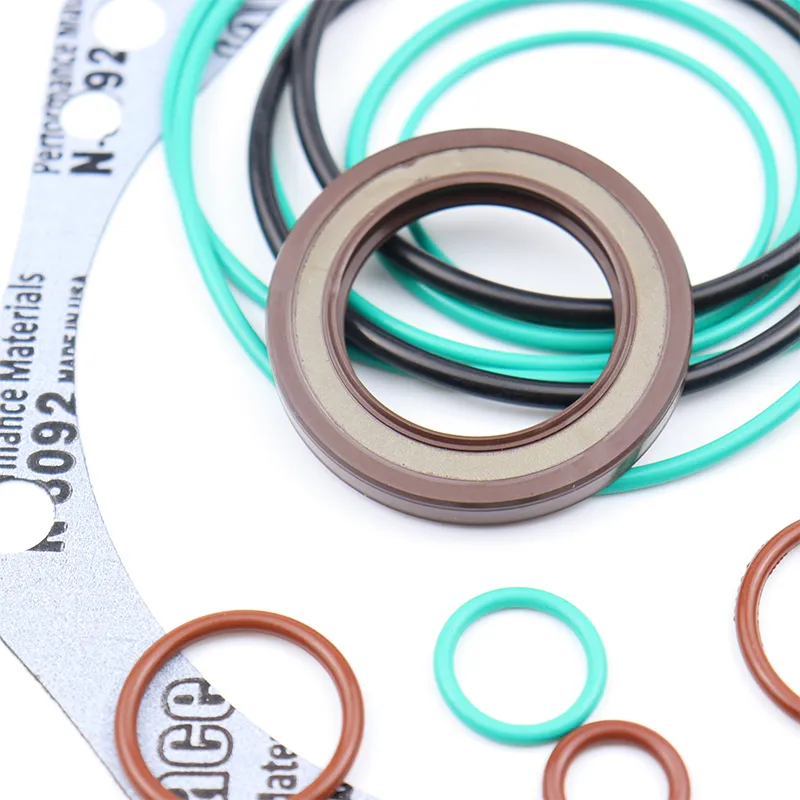

Understanding Gear Pump Seal Kits Essential Components for Efficient Pump Operation

Gear pumps are widely used in various industrial applications due to their reliability, efficiency, and ability to handle a wide range of viscosities. However, like all mechanical systems, gear pumps require regular maintenance and replacement of parts to ensure optimal performance. One critical component that often requires attention is the seal, and this is where gear pump seal kits become essential.

What is a Gear Pump Seal Kit?

A gear pump seal kit is a collection of components designed to replace the seals in a gear pump. These kits typically include multiple types of seals made from various materials suitable for different applications, such as rubber, PTFE, or other elastomers. The primary function of these seals is to prevent leaks of the fluid being pumped, maintain pressure within the system, and protect the internal components from contamination.

Why are Gear Pump Seals Important?

1. Leak Prevention One of the main functions of seals in gear pumps is to keep the pumped fluids contained within the pump body. If the seals fail, the fluid can leak out, leading to loss of product, environmental hazards, and potential safety issues.

2. Maintaining Pressure Seals help maintain the required pressure within the pump. A pressure drop can lead to inefficient performance and may even cause the pump to operate outside of its optimal range, resulting in damage or failure over time.

3. Protection against Contaminants Seals also act as barriers against dirt, dust, and other contaminants from entering the pump’s internal workings. This is critical for maintaining the pump's performance and longevity.

When to Replace Gear Pump Seals

Regular inspections of gear pumps are essential to determine the condition of seals

. Signs that seals may need replacement include- Visual leaks around the pump casing - A drop in pressure readings - Unusual noises during operation - Increased fluid consumption

gear pump seal kit

Replacing the seal kit at the first signs of wear can prevent more extensive damage to the gear pump and is generally more cost-effective than dealing with extensive repairs later.

Selecting the Right Seal Kit

When selecting a gear pump seal kit, it's essential to consider several factors

1. Compatibility The seal kit must be compatible with the specific model of the gear pump. Manufacturers usually provide specifications for the required seal kits, which can be found in the user manual or through direct inquiry.

2. Material Quality The material of the seals is crucial depending on the type of fluid being pumped (e.g., oil, chemicals). For high-temperature or corrosive fluids, special materials like PTFE may be necessary for durability.

3. Application Type Different applications might require different types of seals. For instance, a hydraulic system would demand seals that can withstand high pressure, while a system handling oils may need seals designed to resist lubrication properties.

Installation of Seal Kits

Installing a gear pump seal kit is a task that can typically be performed by maintenance personnel with basic mechanical skills. Following the manufacturer’s instructions is vital for proper installation. The process generally involves

1. Disassembling the pump casing. 2. Removing old seals carefully to avoid damaging the pump housing. 3. Cleaning the sealing surfaces to ensure a proper fit for the new seals. 4. Installing the new seals as per the specific configuration required. 5. Reassembling the pump and testing it for leaks before returning it to service.

Conclusion

In summary, gear pump seal kits are indispensable for maintaining the efficiency and reliability of gear pumps. Regular maintenance, including the timely replacement of seals, can significantly extend the life of the pump and ensure consistent performance. By understanding the importance of seals and the specific qualities of different seal kits, operators can make informed decisions that lead to better equipment management and reduced operating costs. Investing in quality seal kits not only protects the pump but also ultimately contributes to the smooth operation of industrial processes.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories