Ное . 26, 2024 21:28 Back to list

Cylinder Wiper Maintenance and Performance Optimization Tips

Understanding the Importance of Cylinder Wipers in Hydraulic Systems

Hydraulic systems are integral to various industrial applications, ranging from construction equipment to manufacturing machinery. One of the critical components that ensure the reliability and efficiency of these systems is the cylinder wiper. The cylinder wiper, often referred to as a rod seal or wiper seal, plays a vital role in maintaining the performance and longevity of hydraulic cylinders. This article will explore the function, design, and significance of cylinder wipers in hydraulic systems.

What are Cylinder Wipers?

Cylinder wipers are sealing components that help to keep the hydraulic cylinder clean and free from contaminants. These seals are positioned at the end of the cylinder, where the piston rod exits. Their primary function is to wipe away dirt, dust, and other foreign particles that may cling to the piston rod as it extends and retracts. By preventing these contaminants from entering the hydraulic system, cylinder wipers significantly reduce the risk of damage to the hydraulic seals and other internal components.

Why are Cylinder Wipers Essential?

1. Contamination Prevention Hydraulic systems are sensitive to contaminants, which can lead to various issues, including system wear, fluid degradation, and even catastrophic failures. Cylinder wipers act as the first line of defense against these contaminants, ensuring that only clean rod surfaces enter the hydraulic cylinder. This prevents the ingress of particles that could otherwise compromise the system's integrity.

2. Extended Component Lifespan The presence of dirt and debris can lead to abrasion on the seals and other components within the hydraulic cylinder. By effectively wiping away any contaminants, cylinder wipers help extend the lifespan of not only the rod seals but also the entire hydraulic system. This results in reduced maintenance costs and minimizes downtime due to repairs.

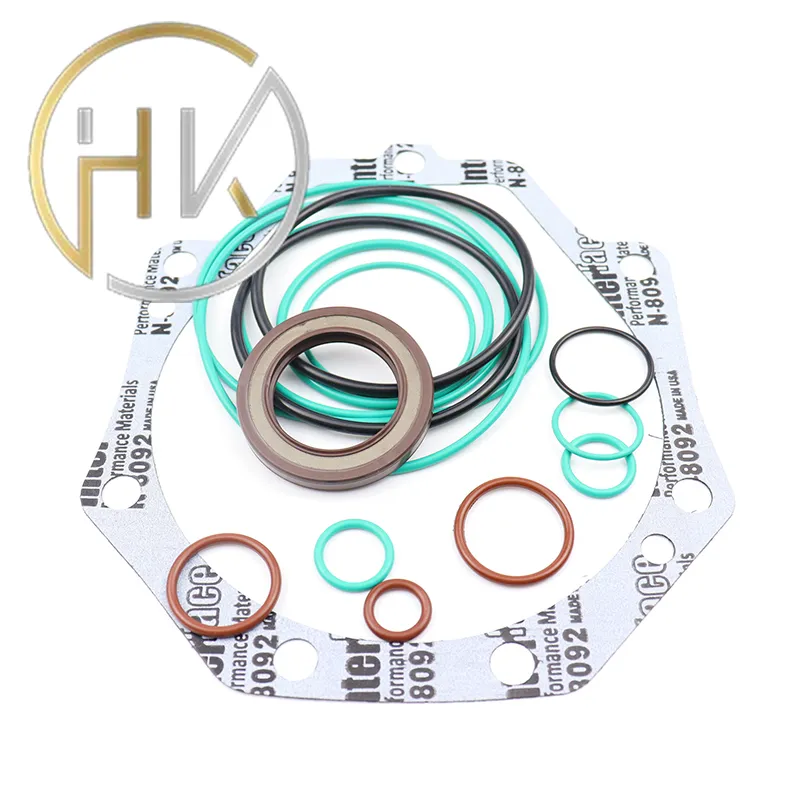

cylinder wiper

3. Improved Performance A clean hydraulic system operates more efficiently. Contaminants can cause friction and impede the smooth movement of the piston, resulting in decreased performance and increased energy consumption. Cylinder wipers ensure that the rod moves freely within the cylinder, optimizing the system's performance and responsiveness.

4. Leak Prevention Hydraulic leaks can be costly and dangerous, leading to loss of fluid and potential environmental hazards. By keeping the piston rod clean, cylinder wipers help maintain the integrity of the sealing surfaces, which reduces the likelihood of leaks occurring. This is particularly important in applications where hydraulic fluid leaks could pose safety risks or lead to regulatory violations.

Design Considerations for Cylinder Wipers

The design of cylinder wipers can vary based on specific application requirements. Factors such as operating pressure, temperature, and the type of hydraulic fluid being used must all be taken into account when selecting a wiper seal. Common materials for cylinder wipers include polyurethane, nitrile rubber, and silicone, each offering distinct properties suited to different environments.

Furthermore, the shape and profile of the wiper seal can influence its wiping performance. Some designs feature a lip that contacts the rod surface more effectively, while others may include features that enhance the seal's ability to repel contaminants. Proper design optimization ensures that cylinder wipers perform efficiently while providing longevity and reliability.

Conclusion

In conclusion, cylinder wipers are a crucial element of hydraulic systems that should not be overlooked. Their ability to prevent contamination, enhance the lifespan of components, improve system performance, and prevent leaks underscores their importance in industrial applications. When selecting and maintaining hydraulic systems, understanding the role of cylinder wipers can lead to more efficient operations and significant cost savings. As technology continues to evolve, the designs and materials used for cylinder wipers are likely to improve, further enhancing the reliability of hydraulic systems across various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories