Окт . 16, 2024 13:07 Back to list

40x52x7 Oil Seal Specifications and Applications for Efficient Machinery Performance

Understanding the 40x52x7 Oil Seal Application and Importance

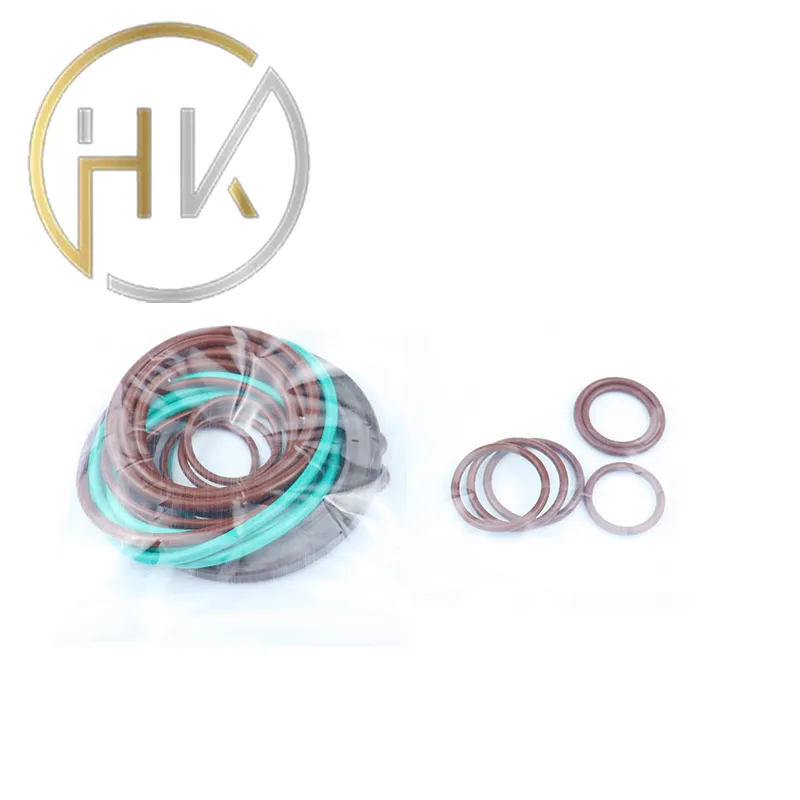

Oil seals play a crucial role in various machinery, ensuring efficient operation by preventing the leakage of lubricants and fluids. Among the different sizes and types of oil seals available in the market, the 40x52x7 oil seal often stands out due to its unique dimensions and efficient sealing capabilities. In this article, we will delve into the specifications, applications, and significance of the 40x52x7 oil seal in various industries.

Specifications

The designation “40x52x7” refers to the dimensions of the oil seal. The first number, 40, indicates the inner diameter in millimeters, while the second number, 52, represents the outer diameter. The last number, 7, denotes the thickness of the oil seal. This specific size is designed to fit a variety of machinery components, providing optimal sealing performance. The material composition of the oil seal typically includes rubber or elastomer, which is flexible and resilient under pressure and temperature variations. The choice of material is crucial, as it must withstand the specific conditions under which the seal operates, such as exposure to chemicals, extreme temperatures, and high pressures.

Applications

The versatility of the 40x52x7 oil seal makes it suitable for numerous applications across different sectors. In the automotive industry, these seals are commonly used in engines, gearboxes, and differential assemblies to prevent oil leakage and protect internal components from dirt and contaminants. Similarly, in industrial machinery, they are used in hydraulic systems, compressors, and pumps, ensuring that lubricants remain contained, thus enhancing the longevity and efficiency of the equipment.

40x52x7 oil seal

Moreover, the 40x52x7 oil seal also finds its place in household appliances, such as washing machines and refrigerators

. Here, the seal plays an integral role in ensuring that the lubricating oil remains within bearings and other moving parts, reducing wear and tear and minimizing the need for maintenance. Its widespread applicability emphasizes the essential role that oil seals play in both industrial and domestic settings.Importance of Proper Maintenance

While the 40x52x7 oil seal is designed for durability, proper maintenance is key to ensuring its effectiveness and longevity. Regular inspections should be conducted to check for signs of wear, deterioration, or leakage. Factors such as excessive heat, contamination from external elements, and improper installation can compromise the performance of the oil seal. If any issues are detected, timely replacement is crucial to prevent further damage to the machinery and costly repairs.

Conclusion

In summary, the 40x52x7 oil seal is a critical component in many mechanical systems, providing reliable sealing solutions that contribute to the efficiency and longevity of various equipment. Its specific dimensions and robust material properties make it an ideal choice for a wide range of applications, from automotive to industrial use. Understanding the importance of this oil seal, along with adopting proper maintenance practices, can lead to enhanced performance and reduced downtime in operations. As technology continues to advance, the role of oil seals like the 40x52x7 will remain significant in ensuring smooth and reliable machinery performance across various domains.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories