Мар . 06, 2025 16:41 Back to list

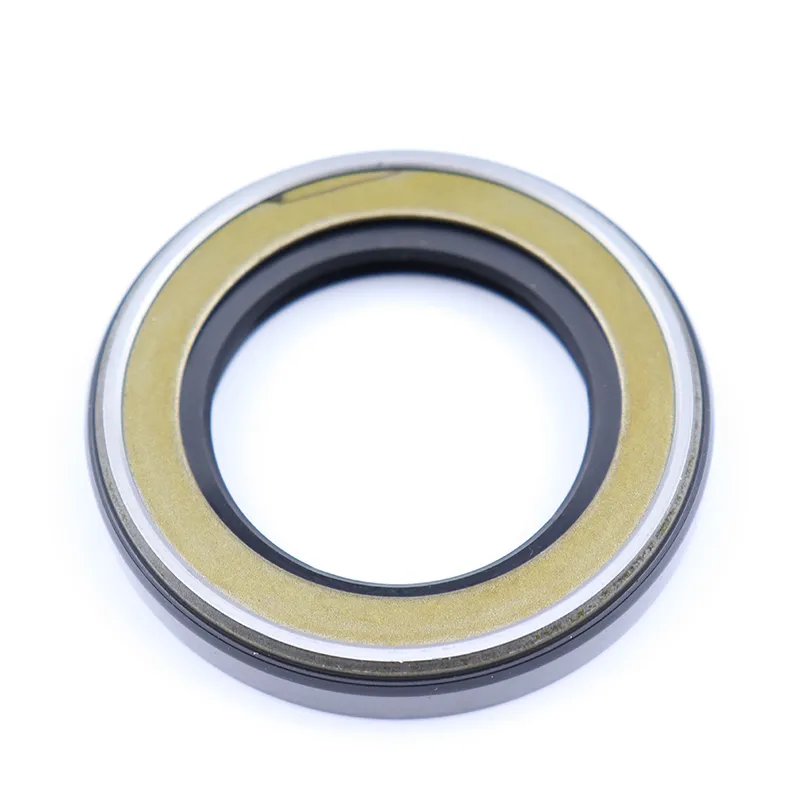

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Moreover, users with extensive experience highlight the importance of precision during installation. A misaligned oil seal, even one as well-crafted as the 32 47 7, can lead to leakage and increased wear and tear on machine parts. Ensuring a snug fit and correct positioning during installation is crucial, and the clear dimension markings of this seal aid professionals in achieving that exactness. Trustworthiness in oil seal performance is underscored by its design features. The double-lip design of the 32 47 7 oil seal ensures dual protection by providing an initial barrier that prevents contaminants and a secondary barrier that keeps the lubricant intact. This duality in design is a testament to the seal's capacity to handle high-pressure environments and rotational speeds, thus assuring seamless operation. In an industry where longevity, efficiency, and reliability are paramount, the 32 47 7 oil seal distinguishes itself by consistently meeting these expectations. Its widespread acclaim among professionals who value durable solutions for complex challenges speaks volumes about its reputation in the market. Finally, a seal's credibility is significantly enhanced when it conforms to industry standards and regulations. The 32 47 7 oil seal not only meets these stringent benchmarks but often exceeds them, providing users with unparalleled confidence in their selection. Incorporating such a reliable component into machinery thus represents an investment in quality and performance, reflecting the core values of expertise, authoritativeness, and trustworthiness in mechanical engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories