Dec . 04, 2024 09:35 Back to list

rod wiper seal

Understanding Rod Wiper Seals Essential Components for Hydraulic Systems

In the realm of hydraulic systems, components function together to ensure efficiency and reliability. Among these, rod wiper seals play a crucial role, yet they often do not receive the recognition they deserve. A rod wiper seal, sometimes simply referred to as a wiper seal, is designed to remove contaminants from the surface of the rod as it enters or exits the cylinder. This article explores the importance, types, functions, and applications of rod wiper seals in hydraulic systems.

Importance of Rod Wiper Seals

Rod wiper seals are vital in extending the life of hydraulic systems. Contaminants such as dirt, dust, and water can cause significant wear and tear on hydraulic components. When these particles enter the hydraulic cylinder, they can damage the shaft and lead to oil leakage, reduced efficiency, and ultimately, system failure. Rod wiper seals act as the first line of defense, preventing these harmful substances from reaching critical parts, thus ensuring smoother operation and prolonging the lifespan of hydraulic equipment.

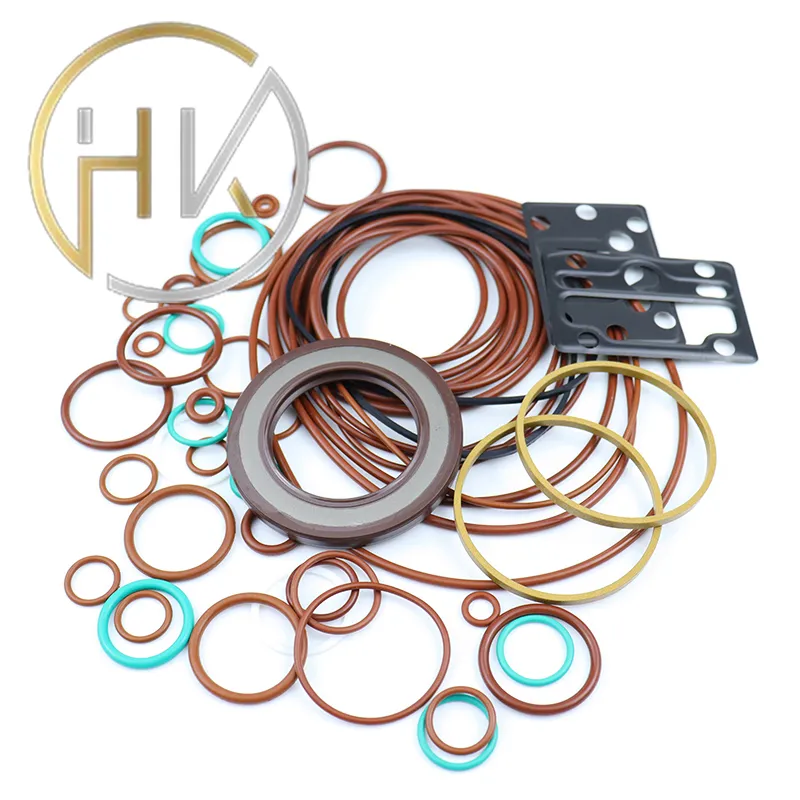

Types of Rod Wiper Seals

Rod wiper seals come in various types and materials, each designed for specific applications. The most common types include

1. Polyurethane Wipers Known for their excellent abrasion resistance and fatigue endurance, polyurethane wipers are suitable for a wide range of environments. They provide a tight seal that can handle high pressure and temperature fluctuations.

2. Nitrile (Buna-N) Wipers Nitrile wipers are popular in applications involving petroleum-based fluids. They offer good resistance to wear and are cost-effective for general use.

3. Fluoroelastomer (FKM) Wipers For harsh chemical environments, fluoroelastomer wipers are ideal due to their exceptional resistance to chemicals and thermal degradation.

4. PTFE Wipers Polytetrafluoroethylene wipers excel in extreme temperature conditions. While they may have lower wear resistance compared to other materials, their low friction properties make them a choice for specific applications.

Functions of Rod Wiper Seals

The primary function of rod wiper seals is to prevent contaminants from entering the cylinder

. However, they serve several additional purposesrod wiper seal

- Fluid Retention While their main role is to keep dirt out, wiper seals also help retain hydraulic fluid, ensuring optimal performance of the hydraulic system.

- Pressure Control Proper sealing ensures that the pressure within the hydraulic system is maintained, leading to consistent performance across various operations.

- Minimizing Leakage Rod wiper seals play a critical role in minimizing any unwanted leakage, further protecting the environment and increasing efficiency.

Applications of Rod Wiper Seals

Rod wiper seals are widely used across various industries, showcasing their versatility. Common applications include

- Construction Equipment Hydraulic excavators, loaders, and backhoes rely on wiper seals to protect hydraulic cylinders from dust and debris on job sites.

- Agricultural Machinery Tractors and harvesters utilize rod wiper seals to ensure that hydraulic systems function optimally, particularly in muddy or dusty conditions.

- Manufacturing Equipment In factories, hydraulic presses and assembly line machinery benefit from rod wiper seals, maintaining performance and minimizing downtime.

- Automotive Applications In vehicles, hydraulic systems such as braking and steering mechanisms incorporate wiper seals to ensure safety and functionality.

Conclusion

Rod wiper seals may be small components, but their impact on hydraulic systems is substantial. By preventing contaminants from entering the system, these seals contribute to efficiency, safety, and longevity of hydraulic equipment. Understanding the types, functions, and applications of rod wiper seals can help engineers and technicians make informed decisions, ensuring systems operate at their best. Whether in construction, agriculture, manufacturing, or automotive industries, the importance of rod wiper seals cannot be overstated—they are integral to the smooth operation of hydraulic systems everywhere.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories