Oct . 13, 2024 00:46 Back to list

Understanding the Functionality of Wiper Rings in Piston Mechanisms

Understanding the Wiper Ring Piston Importance and Functionality

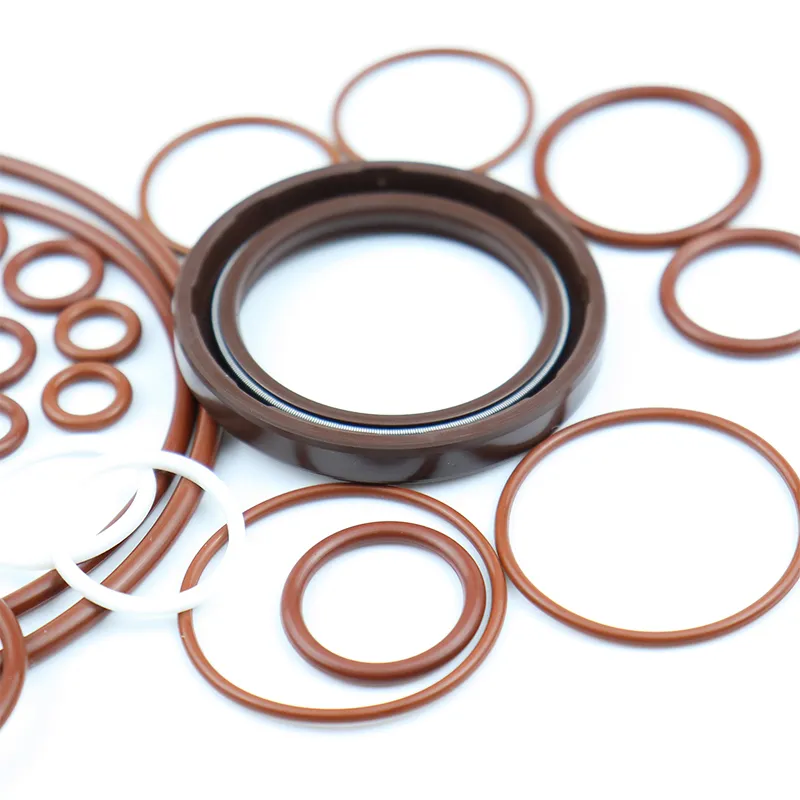

In the domain of mechanical engineering and design, various components play crucial roles in ensuring the efficient operation of machinery. Among these are wiper ring pistons, an essential component in hydraulic and pneumatic systems. The wiper ring, often referred to as a piston wiper, serves a pivotal function in sealing applications, contributing to the integrity and longevity of machinery. This article delves into the wiper ring piston, exploring its design, functionality, and applications in various industries.

What is a Wiper Ring Piston?

A wiper ring piston is a sealing device strategically positioned in hydraulic or pneumatic cylinders. Its primary function is to prevent contaminants, such as dirt and dust, from entering the system while simultaneously retaining the hydraulic or pneumatic fluid within the cylinder. This dual role not only ensures optimal performance but also enhances the longevity of the machinery involved.

Wiper rings are typically made from elastomers or thermoplastics, chosen for their resilience and ability to withstand a variety of operating conditions. The material's properties determine its effectiveness in sealing, wear resistance, temperature range, and compatibility with different fluids.

Design Features

The design of wiper rings can vary depending on the specific application and the type of fluid they are meant to seal. Common characteristics include a flat or slightly conical shape, which aids in the efficient scraping of contaminants from the piston rod as it reciprocates. The edges of the wiper ring are designed to create a tight seal against the surface of the piston rod, ensuring that no debris can pass while allowing for smooth movement.

Additionally, wiper rings often feature grooves or channels that facilitate the collection and drainage of any trapped contaminants. This design not only helps maintain a clean working environment inside the cylinder but also reduces wear and tear on the sealing surfaces, extending the overall life of the system.

wiper ring piston

Functionality in Hydraulic and Pneumatic Systems

In hydraulic systems, maintaining fluid integrity is paramount for efficient operation. The wiper ring piston plays an integral role in achieving this by preventing external contaminants from penetrating the hydraulic fluid. If contaminants were to enter, they could cause significant damage to the system components, leading to reduced efficiency and potential system failure.

In pneumatic systems, which often operate under lower pressures than hydraulic systems, the wiper ring piston likewise helps in maintaining a clean environment. The ingress of moisture or particulate matter can lead to malfunction or compromised performance. Thus, wiper rings are critical for ensuring the reliability of pneumatic operations, especially in high-speed applications where even minor contaminants can result in malfunctions.

Applications Across Industries

The applications of wiper ring pistons are vast and varied. Industries such as automotive, aerospace, manufacturing, and heavy machinery rely heavily on these components. In the automotive sector, wiper rings are commonly found in shock absorbers and general hydraulic systems. For aerospace applications, they are vital in landing gear and hydraulic control systems, where precision and reliability are essential.

In manufacturing, various machines that utilize hydraulic presses or pneumatic systems incorporate wiper ring pistons to preserve the integrity of their operations. Heavy machinery used in construction and mining also employs these wiper rings to ensure optimal performance, even in the most challenging environments.

Conclusion

The wiper ring piston, though often overlooked, is a fundamental component in the world of hydraulics and pneumatics. Its ability to protect systems from contaminants and preserve fluid integrity is critical for ensuring the longevity and efficiency of machinery across numerous industries. As technology continues to evolve, the materials and designs used in wiper ring pistons will likely advance, further enhancing their performance and application potential. Understanding their importance helps engineers and designers appreciate the intricate balance between functionality and reliability in mechanical systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories