Nov . 16, 2024 05:05 Back to list

ross hydraulic motor seal kit

Understanding the Ross Hydraulic Motor Seal Kit

Hydraulic motors are integral components in various industrial applications, providing reliable motion and force through pressurized fluid. Among the essential aspects that influence the performance and longevity of hydraulic motors are their seals. The Ross Hydraulic Motor Seal Kit is designed to address the wear and tear that these seals endure over time, ensuring optimal functioning of hydraulic systems. In this article, we'll explore the significance of hydraulic motor seal kits, the details of the Ross seal kit, and tips for maintenance and installation.

Importance of Hydraulic Motor Seals

Seals in hydraulic motors serve the critical function of preventing fluid leaks. They ensure that hydraulic fluid remains contained within the circuit, allowing the system to maintain pressure and operate efficiently. With time and usage, these seals can degrade due to various factors, including temperature fluctuations, fluid composition, and mechanical wear. When seals fail, it can lead to decreased efficiency, increased operational costs, and potential damage to other components of the hydraulic system.

Overview of the Ross Hydraulic Motor Seal Kit

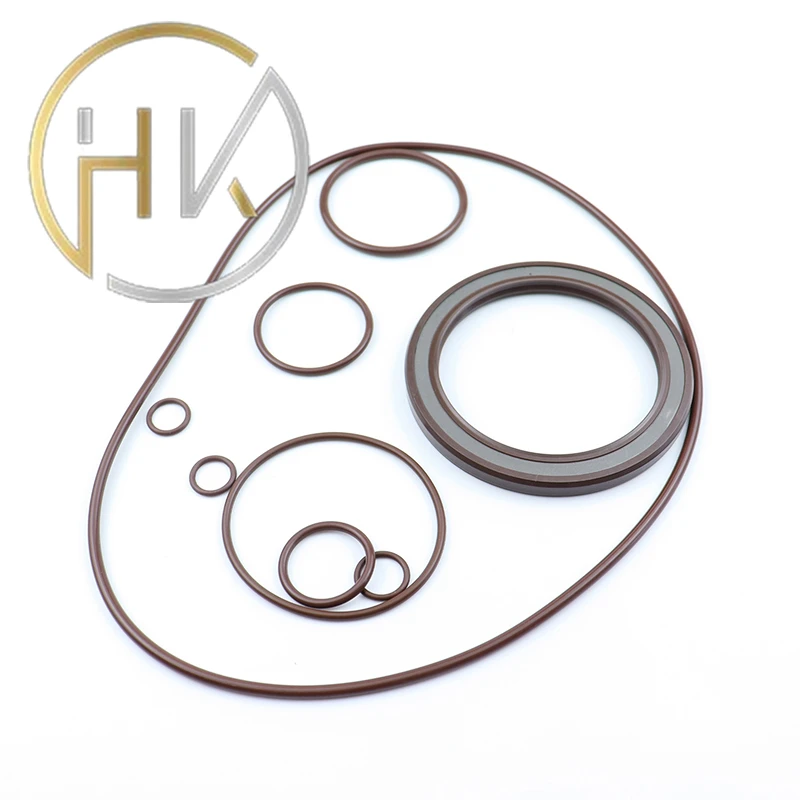

The Ross Hydraulic Motor Seal Kit is designed specifically for Ross hydraulic motors. This quality kit typically contains various components, including O-rings, backup rings, and lip seals. Each component is made from durable materials, engineered to withstand high pressure and abrasive conditions typical in hydraulic applications. The kit is essential for maintenance and repair, allowing technicians to replace worn or damaged seals promptly and effectively.

1. High-Quality Materials The seals in the Ross kit are made from advanced materials that offer resistance to wear, temperature extremes, and fluid degradation. This ensures that the seals will operate effectively in various environments and extend the life of your motor.

2. Comprehensive Kit The kit usually contains all the necessary seals for a complete overhaul of your hydraulic motor, making it easy to address all potential leakage or performance issues in one go. This reduces the need for multiple purchases and simplifies the repair process.

3. Cost-Effective Solution Using a seal kit is a cost-effective approach for maintaining hydraulic motors. Regular replacement of seals can prevent more significant issues that could lead to costly repairs or system failures.

ross hydraulic motor seal kit

Installation Tips for the Ross Seal Kit

To ensure the optimal performance of the Ross Hydraulic Motor Seal Kit, proper installation is crucial. Here are some essential tips for the installation process

1. Clean the Work Area Before beginning the installation, ensure that your work environment is clean. Debris or dirt can contaminate the hydraulic system, leading to premature seal failure.

2. Inspect Components Before installing the new seals, inspect all related components of the hydraulic motor. Look for signs of wear or damage on items such as the housing and bearing surfaces. Any imperfections may need to be addressed before sealing.

3. Use Proper Tools Utilize appropriate tools for the installation process to avoid damaging the seals. A seal installation tool can help ensure that the seals are seated correctly without causing any cuts or tears.

4. Lubricate Seals Lightly lubricate the seals with hydraulic fluid before installation. This ensures easy placement and helps in creating a better seal once the motor is back in operation.

5. Follow Manufacturer Guidelines Always refer to the manufacturer’s installation instructions. This will help you avoid common mistakes and ensure that the seals are installed adequately for the specific model of the Ross hydraulic motor you are working with.

Conclusion

The Ross Hydraulic Motor Seal Kit offers a comprehensive solution for maintaining the efficiency and longevity of hydraulic motors. Seals are vital for preventing leaks and maintaining pressure, and regular replacement can prevent costly repairs down the line. By understanding the importance of these seal kits, familiarizing yourself with the components, and following proper installation and maintenance protocols, you can ensure that your hydraulic system operates smoothly and efficiently. Investing in the right hydraulic motor seal kit is not just about immediate repair; it’s about safeguarding the entire hydraulic system for the long term. Whether you are a maintenance technician or a DIY enthusiast, the Ross Hydraulic Motor Seal Kit is a critical part of your hydraulic maintenance toolkit.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories