Dec . 07, 2024 09:58 Back to list

gearbox seals

Understanding Gearbox Seals Importance, Types, and Maintenance

Gearbox seals play a critical role in the overall functionality and longevity of machinery that utilizes gear systems. These seals are vital components designed to prevent the leakage of lubricants while keeping contaminants out of the gearbox. By ensuring a proper seal, they contribute significantly to the efficiency and performance of gearboxes used in various applications, from automotive transmissions to industrial machinery.

Importance of Gearbox Seals

One of the primary functions of gearbox seals is to maintain the integrity of lubricants within the gearbox. Lubricants are essential for reducing friction between moving parts, thus preventing wear and overheating. If a seal fails, not only can valuable lubricant leak out, but dirt, dust, and other contaminants can enter the gearbox, leading to increased wear and potential failure of internal components. This can result in costly repairs and significant downtime for industrial and automotive systems alike.

Moreover, the correct functioning of gearbox seals enhances energy efficiency. Leaks can cause a drastic drop in system performance, requiring additional power consumption to maintain operational levels. In industrial contexts, this translates to higher operational costs, which can significantly impact the overall profitability of a venture. By ensuring that seals are well-maintained and functioning correctly, businesses can save money and contribute to more sustainable operations.

Types of Gearbox Seals

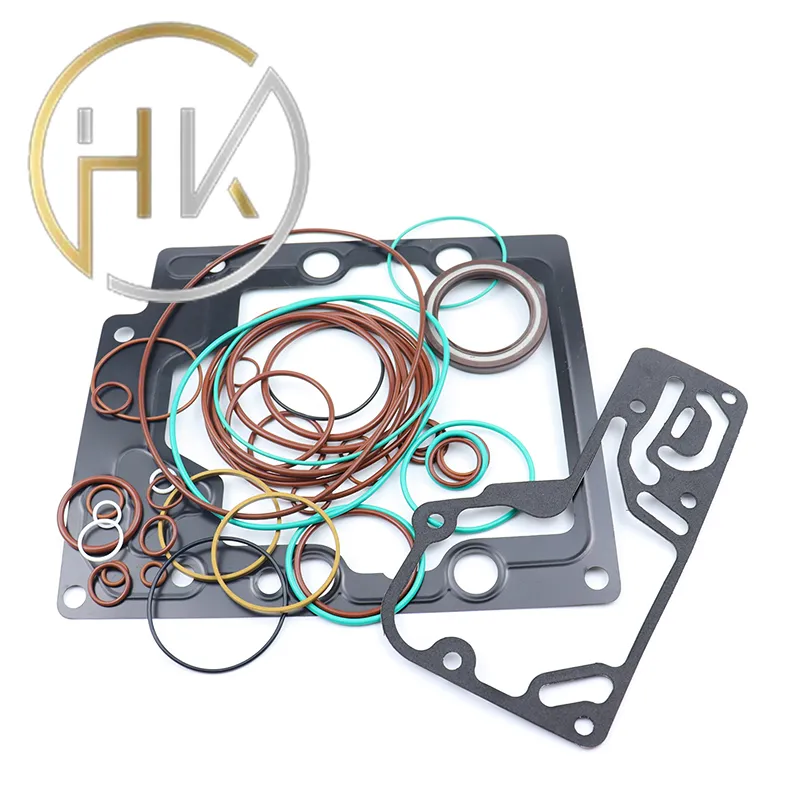

There are several types of seals used in gearboxes, each designed for specific applications and operating conditions. The most common types include

1. Oil Seals These seals are specifically designed to retain lubricating oils within the gearbox while preventing contamination from external elements. They are made of flexible materials, such as rubber, that can compress and create a tight seal.

gearbox seals

2. O-Rings Often used in conjunction with other seal types, O-rings offer excellent sealing properties and are versatile across various applications. They prevent leakage between two surfaces and are easy to install and replace.

3. Mechanical Seals These seals are commonly used in high-pressure environments. They feature a design that allows for compression between two surfaces, preventing fluid escape and contamination.

4. Lip Seals Lip seals typically feature a flexible lip that makes contact with a rotating shaft. They are often used in automotive applications, such as in the transmission, to prevent fluid from leaking during dynamic operation.

Maintenance of Gearbox Seals

Regular maintenance of gearbox seals is crucial for ensuring optimal performance. Operators should regularly inspect seals for signs of wear, cracking, or deformation. Any visible damage can indicate that a seal is failing and should be replaced before it leads to oil leaks or contamination.

Additionally, monitoring lubricant levels and the presence of contaminants can provide insights into the condition of the seals. If fluid levels drop unexpectedly or if there is an increase in debris found in the lubricant, it may be time to investigate the potential failure of seals.

In conclusion, gearbox seals are essential components that significantly impact the efficiency, performance, and longevity of gear systems. Understanding their types and maintaining them appropriately ensures machinery operates smoothly and cost-effectively. By prioritizing proper seal maintenance, businesses can prevent costly repairs, avoid downtime, and achieve greater overall operational efficiency.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories