Nov . 09, 2024 02:17 Back to list

Comparing Dust Seals and Oil Seals for Optimal Performance and Applications

Dust Seal vs. Oil Seal Understanding the Differences and Applications

When it comes to the protection of machinery and equipment, seals play an essential role in maintaining optimal performance and extending equipment lifespan. Among various types of seals, dust seals and oil seals are two commonly used types, each designed for specific purposes. Understanding their differences, applications, and the environments in which they are used is crucial for selecting the appropriate seal for any given task.

What is a Dust Seal?

A dust seal, also known as a dust cover or dirt seal, is primarily designed to prevent the entry of dirt, dust, and other contaminants into sensitive areas of machinery. This type of seal is typically made of flexible materials, such as rubber or polyurethane, which help create a barrier against external particles. Dust seals are not generally used to contain fluids; instead, their primary focus is on providing protection against solid contaminants.

What is an Oil Seal?

An oil seal, on the other hand, is designed to retain lubricating oils and other fluids within a mechanism while preventing any leakage. Oil seals typically feature a more complex design, often incorporating a metal casing and a rubber or elastomeric lip that makes contact with the rotating shaft. This lip creates a tight seal against the rotation, effectively keeping oil in and contaminants out. Oil seals are crucial in applications where lubrication is necessary to reduce friction and wear between moving parts.

Key Differences

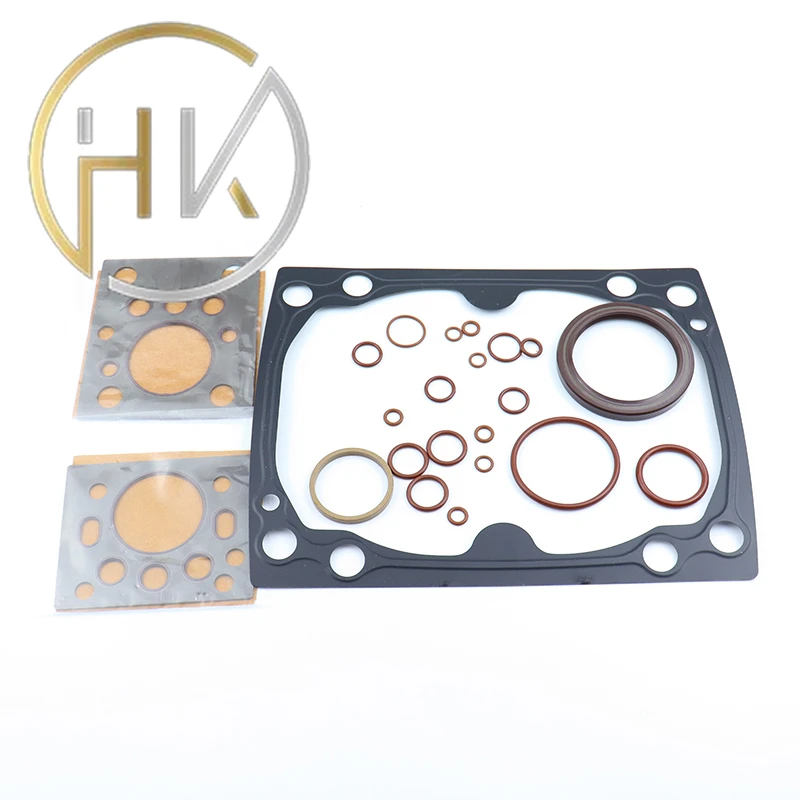

dust seal vs oil seal

1. Purpose - Dust seals are intended to protect against solid particles, whereas oil seals are designed to contain liquids, primarily lubricants. 2. Design - Dust seals usually consist of simpler designs and materials that are effective against abrasion and wear caused by dust and dirt. In contrast, oil seals have a more intricate design featuring a lip mechanism that tests against pressure from the fluid within the cavity. 3. Applications - Dust seals are commonly found in various machinery, such as construction equipment, where exposure to dust and dirt is prevalent. They are also used in automotive applications, such as around wheel bearings and suspension systems. Oil seals are found in applications where the retention of lubricants is critical, for example in engines, gearboxes, and hydraulic systems.

4. Material Composition - While both types of seals can be manufactured from rubber, oil seals often incorporate additional materials like metals or polymer blends to withstand higher pressure and temperature conditions, as they deal with both oil and moving parts.

Applications in Industry

The choice between a dust seal and an oil seal can significantly impact equipment reliability and maintenance. For instance, in industries such as manufacturing, where heavy machinery operates in dusty environments, installing dust seals can prevent contaminants from entering bearings and gears, thus minimizing wear and tear. On the other hand, industries like automotive and aerospace rely heavily on oil seals to prevent oil leaks, maintain pressure, and ensure efficient operation of engines and hydraulic systems.

Conclusion

In conclusion, while both dust seals and oil seals serve to protect machinery and enhance performance, they have distinct functions and designs tailored to their specific purposes. Understanding the differences between these two types of seals, their applications, and the environments in which they function is vital for industries reliant on machinery. Selecting the right seal not only prolongs equipment life but also ensures optimal operation, reducing downtime and maintenance costs. By recognizing the unique characteristics of dust seals and oil seals, engineers and technicians can make informed decisions that lead to improved efficiency and performance in their respective fields.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories