Lap . 19, 2024 00:15 Back to list

Alternative Solutions for Swivel Hub Seal Design and Functionality in Mechanical Systems

Understanding Swivel Hub Seals Importance and Functionality

Swivel hub seals play a crucial role in various mechanical applications, particularly in equipment that requires rotational movement while maintaining a barrier against contaminants. These seals are vital for the optimal functionality of machinery, including those in the automotive, aerospace, and industrial sectors. By providing an effective sealing solution, swivel hub seals ensure that lubricants remain contained within the hub, thus enhancing performance and longevity.

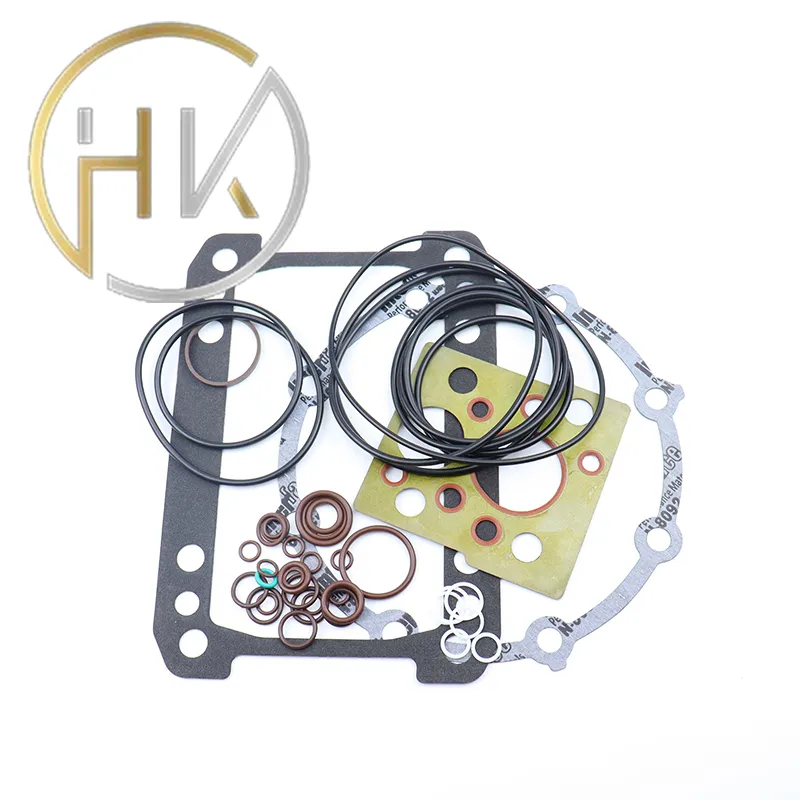

At its core, a swivel hub seal consists of several components designed to work together to create a reliable barrier

. The primary materials used in manufacturing these seals include rubber, elastomers, and advanced polymers, chosen for their ability to withstand environmental factors such as temperature fluctuations, pressure variations, and exposure to chemicals. The design of a swivel hub seal often features a lip that forms a tight fit against a rotating shaft, which is critical in preventing the leakage of lubricants and the ingress of dirt, dust, or other contaminants.swivel hub seal

One of the main advantages of swivel hub seals is their ability to accommodate movement. Unlike static seals, which are designed for fixed components, swivel hub seals allow for rotational and angular movements. This makes them ideal for applications such as wheel bearings, where the hub must rotate smoothly without compromising the seal's integrity. The adaptability of these seals ensures that they can handle the dynamic conditions found in machinery that experiences frequent movement.

The failure of a swivel hub seal can lead to severe consequences, including equipment malfunctions, increased wear and tear, and costly downtimes. Regular maintenance and inspection are crucial to ensure the continued effectiveness of these seals. Operators should be vigilant in checking for signs of wear, such as cracks or distortions, which can indicate that a seal needs replacement. By proactively managing seal integrity, businesses can minimize the risk of operational disruptions.

In conclusion, swivel hub seals are essential components that provide effective solutions for maintaining the efficiency and reliability of rotating machinery. Their unique design allows for flexibility while ensuring protection against contaminants. As technology evolves, the materials and engineering techniques used to create these seals will continue to improve, enhancing their performance and lifespan. Understanding the importance of swivel hub seals will help industries maintain their equipment effectively, resulting in optimized operations and reduced maintenance costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories