ພ.ຈ. . 17, 2024 09:56 Back to list

Understanding Single Acting Piston Seals for Enhanced Performance and Reliability in Machinery

Understanding Single Acting Piston Seals Functionality and Applications

Single acting piston seals are critical components in various hydraulic and pneumatic systems. These seals play an essential role in ensuring the efficient operation of pistons by preventing fluid leakage from the working chamber, thus maintaining system pressure and functionality. Their design and function are tailored to meet the requirements of specific applications, making them indispensable in many industries, including automotive, aerospace, and manufacturing.

Functionality of Single Acting Piston Seals

Single acting piston seals are engineered to perform effectively in scenarios where pressure is applied to only one side of the piston. This design is typically used in systems that require the piston to move in a single direction, relying on the pressure of the fluid to drive the motion. As the hydraulic or pneumatic fluid enters the chamber behind the piston, the seal prevents the fluid from escaping, thus allowing for a controlled and powerful movement of the piston.

The primary function of these seals is to provide a reliable barrier that withstands high pressures while minimizing friction between the piston and the cylinder wall. This is achieved through the use of durable materials, such as elastomers or polymers, which are chosen based on their resistance to wear, temperature, and chemical exposure. The seal must be properly fitted to the piston and the cylinder to ensure efficient sealing and to extend the lifecycle of both the seal and the system it operates within.

Types and Materials of Single Acting Piston Seals

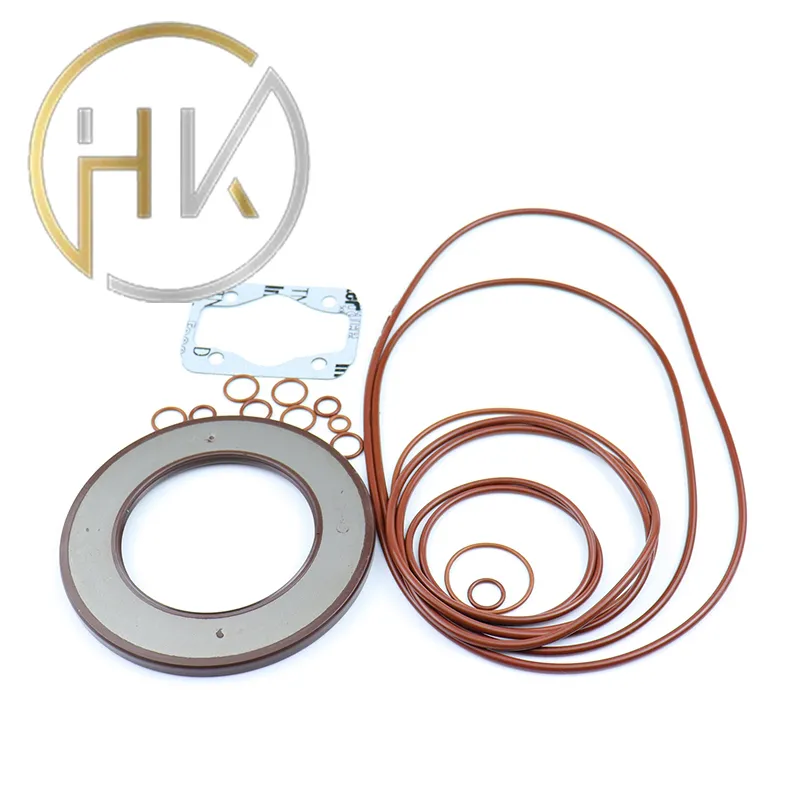

The variety of single acting piston seals available on the market accommodates a range of applications. Common types include U-cup seals, V-rings, and lip seals. Each type has its advantages regarding sealing performance, ease of installation, and compatibility with different fluids.

single acting piston seal

Materials utilized for single acting piston seals include nitrile rubber, polyurethane, and PTFE (polytetrafluoroethylene)

. Nitrile rubber is well-known for its excellent resistance to petroleum-based oils, making it suitable for automotive applications. Polyurethane, on the other hand, offers superior wear resistance and is often used in applications involving dynamic movement, while PTFE is sought after in situations where chemical resistance is paramount.Applications in Various Industries

Single acting piston seals are employed across a plethora of industries. In manufacturing, these seals are integral to hydraulic presses and injection molding machines, where precise control over pressure is crucial. In the automotive sector, they are found in brake systems and power steering components, ensuring reliable operation under high-stress conditions.

In aerospace applications, the need for reliable sealing solutions is elevated due to the harsh environmental conditions encountered. Single acting piston seals are used in landing gear and hydraulic systems, reinforcing safety and performance standards.

Conclusion

In summary, single acting piston seals are vital components that ensure the efficient functioning of hydraulic and pneumatic systems. Their ability to prevent fluid leakage while allowing for controlled movement is essential across various industries. Understanding the types, materials, and applications of these seals helps engineers and manufacturers select the right sealing solutions, ultimately impacting the reliability and efficiency of their systems. As technology continues to advance, so too does the design and application of piston seals, ensuring they meet the ever-evolving demands of modern machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories