ທ.ວ. . 12, 2024 14:26 Back to list

seal kit hydraulic

Understanding Seal Kits for Hydraulic Systems

Hydraulic systems play a crucial role in various industrial applications, from construction machinery to automotive systems, enabling precise control and efficient power transmission. At the heart of these systems are seal kits, components that ensure the reliable and efficient operation of hydraulic machinery. This article will delve into the significance of seal kits, their components, and their function in hydraulic systems.

What is a Hydraulic Seal Kit?

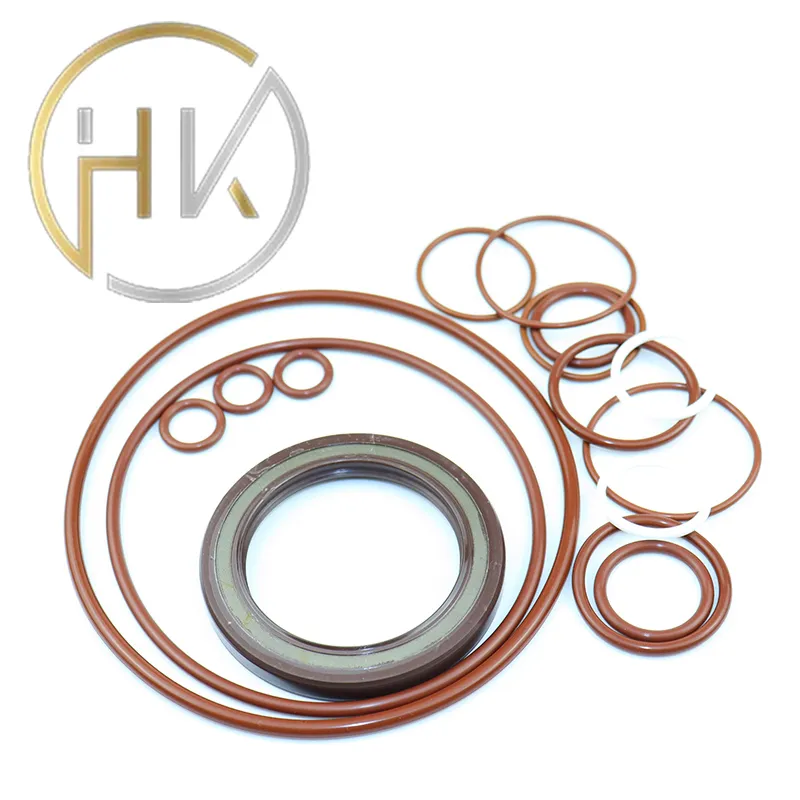

A hydraulic seal kit is a collection of seals, o-rings, and other components designed to maintain the integrity of hydraulic systems by preventing fluid leaks. These kits are essential in various hydraulic applications, including hydraulic cylinders, pumps, and motors, where hydraulic fluid is used to transmit power. Seal kits are customized for specific equipment, ensuring a proper fit and optimal performance.

Components of a Seal Kit

A typical hydraulic seal kit includes

1. Seals The primary function of seals is to prevent hydraulic fluid from leaking out of the system. They can be made from various materials, including rubber, polyurethane, and PTFE, each chosen for its ability to withstand specific pressures, temperatures, and fluid types.

2. O-Rings These are circular cross-section seals that fit into grooves to provide a leak-proof barrier. O-rings are critical in static and dynamic sealing applications and must be carefully selected based on the application requirements.

3. Back-Up Rings These rings are used alongside O-rings to prevent extrusion, especially in high-pressure applications. They provide additional support and extend the lifespan of O-rings.

4. Wipers or Scrapers These components are installed at the outer ends of cylinders to keep dirt, debris, and contaminants away from the sealing surfaces, thereby enhancing the overall performance and durability of the hydraulic system.

5. Guides or Bushings These components help to guide the movement of the piston, ensuring smooth operation and reducing wear on the seals.

seal kit hydraulic

Importance of Seal Kits in Hydraulic Systems

The effectiveness of a hydraulic system largely depends on the performance of its seals. Proper sealing not only prevents costly fluid leaks but also maintains pressure within the system, which is vital for the efficient operation of hydraulic machinery. Some of the critical reasons for the importance of seal kits include

1. Efficiency and Performance Leaks in hydraulic systems can lead to a significant loss of efficiency and power. Seal kits help maintain optimal fluid levels and pressure, ensuring that machinery operates at peak performance.

2. Cost Savings By preventing leaks, seal kits reduce maintenance costs and fluid replacement expenses. Additionally, they help avoid costly downtime and repairs associated with hydraulic system failures.

3. Safety Hydraulic fluid leaks can pose serious safety hazards, particularly in industrial environments. Properly functioning seal kits ensure the safety of operators and equipment by minimizing the risk of spills and accidents.

4. Extended Equipment Life Seals protect critical components of hydraulic systems from wear and contamination. By maintaining the integrity of the hydraulic circuit, seal kits contribute to the longevity of hydraulic machinery.

Choosing the Right Seal Kit

Selecting the appropriate seal kit is crucial for ensuring optimal performance. Factors to consider include

- Compatibility Ensure that the materials used in the seals are compatible with the type of hydraulic fluid being used. - Pressure and Temperature Ratings Choose seals that can withstand the specific pressure and temperature conditions of the application. - Manufacturer Specifications Always refer to the manufacturer’s guidelines for the specific equipment to ensure proper fit and function.

In conclusion, seal kits are indispensable components of hydraulic systems that ensure efficient operation, prevent leaks, and promote the longevity of machinery. By understanding the components and significance of these kits, operators and maintenance personnel can make informed decisions, leading to improved performance and reduced costs in hydraulic applications. Regular inspections and maintenance of seal kits are essential for keeping hydraulic systems running smoothly, highlighting the vital role they play in hydraulic technology.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories