ພ.ຈ. . 22, 2024 03:46 Back to list

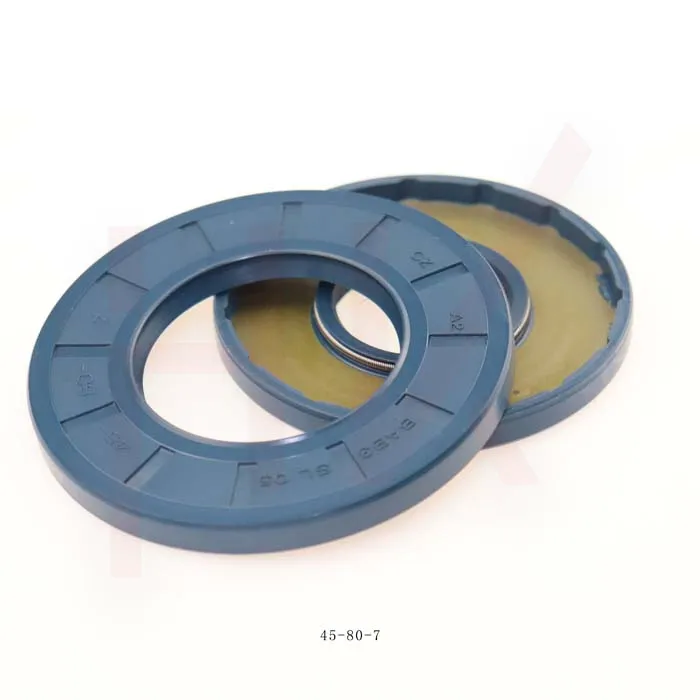

seal kit for cylinder

The Importance and Utility of Seal Kits for Cylinders

In various industrial applications, the functionality and efficiency of hydraulic and pneumatic systems heavily depend on seals and seal kits for cylinders. These components are essential for maintaining pressure, preventing leaks, and ensuring the smooth operation of machinery. As industries evolve and technology advances, understanding the significance of seal kits has become increasingly critical.

What is a Seal Kit?

A seal kit typically comprises various seals, O-rings, and gaskets designed to fit specific types of hydraulic or pneumatic cylinders. These kits are tailored for different applications, ensuring they can withstand the unique conditions they will encounter, such as pressure variations, temperature fluctuations, and exposure to various fluids. By using the correct seal kit, operators can prevent leakage, reduce wear, and prolong the life of the cylinder.

Key Components of Seal Kits

1. Seals These are the primary components that prevent fluid from leaking out of the cylinder. Depending on the design and application, seals can include rod seals, piston seals, and buffer seals.

2. O-Rings O-rings serve as static and dynamic seals that fill the gap between two parts. They help in maintaining a tight seal while allowing for movement.

3. Back-Up Rings These components are used with O-rings to prevent extrusion under high pressure. They provide additional support and enhance the seal's durability.

4. Gaskets Used in various interfaces, gaskets act as seals between two surfaces, preventing leaks.

5. Lubricants Many seal kits include lubricants that ensure the seals operate smoothly and have a longer life. Proper lubrication reduces friction, wear, and tear, resulting in optimal performance.

The Role of Seal Kits in Industrial Applications

Seal kits play a crucial role in several industries, including automotive, construction, manufacturing, and aerospace. Here’s a closer look at their importance

- Hydraulic Systems In hydraulic machinery, seals are vital for ensuring that pressurized fluids do not escape. A seal failure can lead to a complete system breakdown, resulting in costly repairs and downtime.

- Pneumatic Systems In pneumatic applications, where air is used to power machinery, seals help maintain pressure and ensure efficiency. Leakage in pneumatic systems can lead to performance inefficiencies and increased operational costs.

seal kit for cylinder

- Rotational Motion In applications involving rotational movement, specialized seals, such as rotary seals, are vital for preventing fluid leakage along rotating shafts

.Benefits of Using Quality Seal Kits

- Enhanced Reliability Quality seal kits reduce the risk of failure, ensuring that machinery operates smoothly and efficiently. This reliability is crucial in high-stakes environments where downtime can be costly.

- Cost-Effectiveness While the initial investment in quality seal kits may be higher, they are more durable and effective in preventing leaks. This durability translates into lower maintenance costs and extended equipment life.

- Safety A malfunctioning seal due to wear or material fatigue can lead to hazardous situations, particularly in high-pressure systems. Using quality seal kits minimizes the risk of accidents and promotes a safer working environment.

Choosing the Right Seal Kit

When selecting seal kits for cylinders, several factors should be considered

1. Compatibility Ensure that the seal kit is compatible with the specific cylinder model and the fluids it will encounter.

2. Material Different materials are suited for different applications; for instance, nitrile rubber is commonly used for petroleum-based fluids, while fluorocarbon is better for high-temperature applications.

3. Application Conditions Consider the operating environment, including temperature, pressure, and types of fluids, to select the appropriate seals.

4. Quality Standards Opt for kits that meet industry quality standards to guarantee that you receive reliable and durable seals.

Conclusion

In summary, seal kits for cylinders are indispensable components that ensure the reliable operation of hydraulic and pneumatic systems. By preventing leaks and maintaining pressure, they enhance efficiency, reduce downtime, and improve safety across various industrial applications. An informed selection of seal kits based on compatibility, material, and application conditions will contribute significantly to the longevity and performance of your machinery. As industries continue to evolve, the emphasis on quality seal kits will grow, underscoring their critical role in modern mechanical systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories