ພ.ຈ. . 24, 2024 20:23 Back to list

Hydraulic Motor Repair Kit for Efficient Mechanical Performance and Maintenance Solutions

Understanding Hydraulic Motor Rebuild Kits A Comprehensive Guide

Hydraulic motors are vital components in various industrial applications, providing the necessary power to convert hydraulic energy into mechanical movement. Over time, these motors can suffer from wear and tear due to prolonged usage, leading to decreased efficiency and potential failure. To restore their functionality, many operators opt for hydraulic motor rebuild kits. This article explores what a rebuild kit is, its components, the benefits of using one, and important considerations during the rebuild process.

What is a Hydraulic Motor Rebuild Kit?

A hydraulic motor rebuild kit is a carefully curated collection of parts designed to restore a hydraulic motor to its original condition. These kits include various components that may have worn out or become damaged, ensuring that the motor operates efficiently and reliably once again. Typical items found in a rebuild kit include seals, gaskets, bearings, and occasionally, larger components like pistons or rotors.

Key Components of a Rebuild Kit

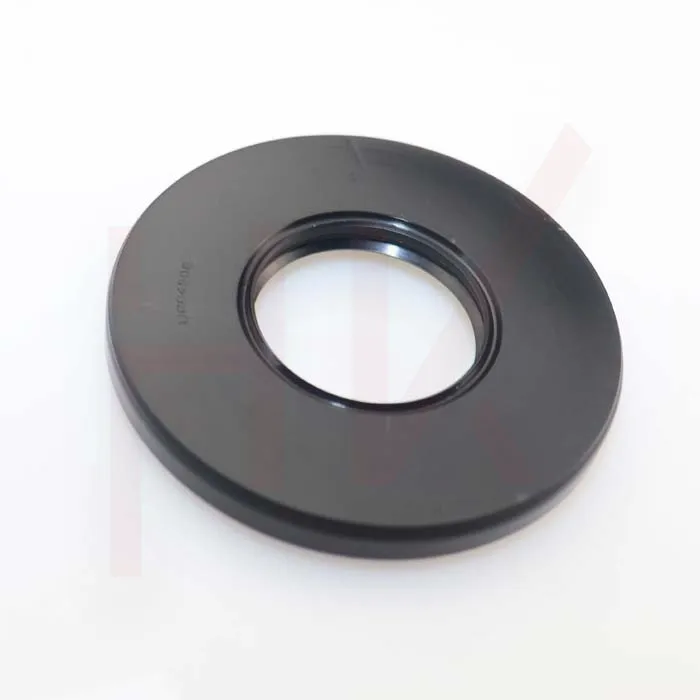

1. Seals and O-Rings These components prevent hydraulic fluid from leaking out of the motor. Over time, exposure to heat and pressure can cause these seals to degrade, leading to performance issues.

2. Gaskets Similar to seals, gaskets create a tight fit between two surfaces to prevent leaks and keep contaminants out. A good rebuild kit will include both new seals and gaskets.

3. Bearings Bearings support the moving parts of the motor. If they wear out, they can cause increased friction, noise, and eventually lead to motor failure.

4. Pistons and Vanes In some kits, you might find replacement pistons or vanes, which directly affect the motor's ability to convert hydraulic energy into motion.

5. Instruction Manual A quality rebuild kit usually comes with a manual detailing the assembly process and tips for installation, ensuring that users can successfully rebuild their hydraulic motors.

Benefits of Using a Rebuild Kit

hydraulic motor rebuild kit

1. Cost-Effective Solution Rebuilding a hydraulic motor with a kit is often significantly cheaper than replacing the entire motor. This approach allows you to extend the life of the equipment without incurring heavy costs.

2. Reduction in Downtime By using a rebuild kit, operators can minimize downtime associated with equipment failure. The process can be faster than sourcing a new motor and allows for quicker repairs.

3. Improved Performance After a rebuild, motors can operate as if they were new, improving efficiency and performance. This can lead to better overall productivity for the operation employing the hydraulic motor.

4. Customization Many rebuild kits offer options tailored to specific motor models and operating conditions, allowing users to select parts that suit their unique needs.

Considerations for Rebuilding a Hydraulic Motor

1. Compatibility Ensure the rebuild kit is compatible with your specific hydraulic motor model. Using the wrong parts can lead to further damage or inadequate performance.

2. Quality of Components Not all kits are created equal. It’s crucial to choose a rebuild kit from reputable manufacturers, as lower-quality components may lead to faster wear and failure.

3. Expertise Required Depending on your experience with hydraulic systems, you may want to consult with a professional during the rebuild process. Proper installation and attention to detail are essential for a successful rebuild.

4. Regular Maintenance After rebuilding your motor, establish a routine maintenance schedule to prolong the lifespan of the motor and prevent future failures. This includes regular checks of fluid levels, monitoring for leaks, and inspecting components for wear.

Conclusion

Hydraulic motor rebuild kits are invaluable resources for maintaining and restoring the functionality of hydraulic motors. By providing high-quality components designed for specific motor models, these kits allow for cost-effective repairs that enhance performance and reduce downtime. Armed with the right tools, knowledge, and a reliable rebuild kit, operators can ensure their hydraulic systems remain efficient and productive for years to come. Investing time in understanding the rebuild process and following best practices will ultimately lead to a smoother operation and improved equipment lifespan.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories