ພ.ຈ. . 18, 2024 18:19 Back to list

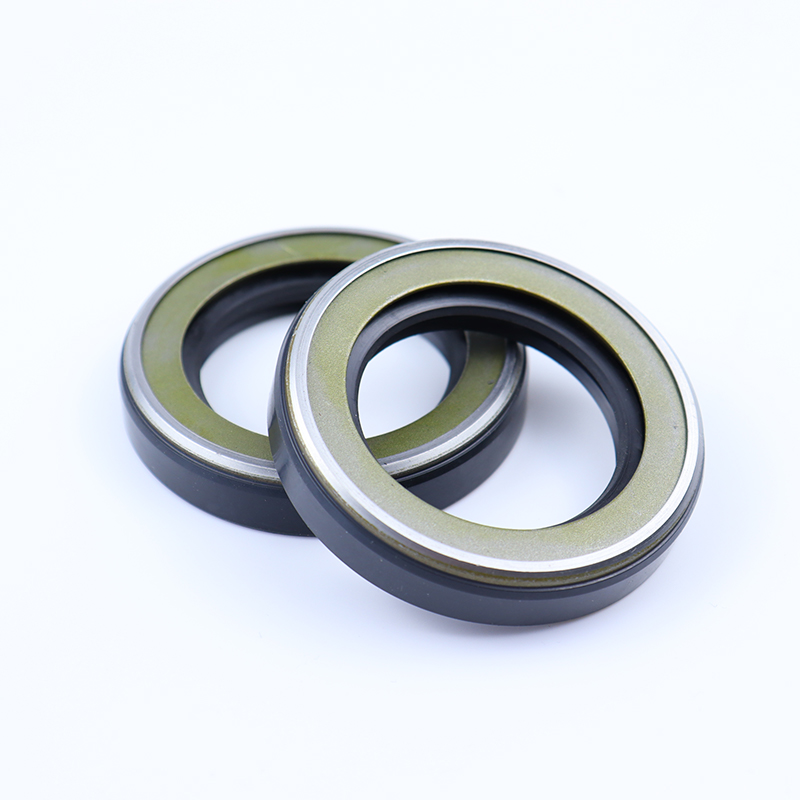

hydraulic cylinder oil seal kit

Understanding Hydraulic Cylinder Oil Seal Kits An Essential Component for Fluid Power Systems

Hydraulic systems play a pivotal role across various industries, powering machinery and equipment through the utilization of pressurized fluid. At the heart of these systems, hydraulic cylinders convert hydraulic energy into mechanical force, enabling movements and functions that are integral to operations in factories, construction sites, and vehicles. One of the critical components of hydraulic cylinders that ensures their efficiency and longevity is the oil seal kit.

What is a Hydraulic Cylinder Oil Seal Kit?

A hydraulic cylinder oil seal kit comprises various seals and packing components specifically designed to prevent hydraulic fluid leakage and contamination within the cylinder. These kits typically include O-rings, rod seals, gland seals, and backup rings, each serving a specialized purpose. The primary function of the oil seal kit is to facilitate the smooth operation of the hydraulic cylinder while safeguarding the hydraulic fluid from external contaminants and maintaining pressure within the system.

Importance of Oil Seal Kits

1. Leak Prevention One of the most significant issues in hydraulic systems is leakage, which can lead to reduced efficiency, increased operational costs, and environmental hazards. Oil seal kits are engineered to create a robust barrier against leaks, ensuring that hydraulic fluid remains confined within the cylinder.

2. Contamination Protection Hydraulic systems are vulnerable to dirt, dust, and other particulate matter, which can lead to severe damage and decreased performance. A quality oil seal kit prevents contaminants from entering the system, prolonging the life of the hydraulic cylinder and its components.

3. Pressure Maintenance Hydraulic systems operate under high pressure, and maintaining this pressure is crucial for optimal performance. The seals in an oil seal kit are designed to withstand significant pressure, ensuring that the system functions as intended without unintentional pressure loss.

4. Operational Efficiency Proper sealing means that the hydraulic cylinders can operate smoothly without excessive wear and tear, leading to improved operational efficiency. This efficiency not only enhances productivity but also reduces the need for frequent repairs and replacements.

Types of Oil Seals in Hydraulic Cylinder Kits

1. Rod Seals These seals are placed at the rod's exit point from the cylinder and prevent hydraulic fluid from leaking out while allowing the rod to move freely. They are integral in maintaining pressure inside the cylinder.

hydraulic cylinder oil seal kit

2. Gland Seals Positioned at the gland or end cap of the cylinder, gland seals help keep the hydraulic fluid contained while offering the necessary resistance to external contaminants.

3. O-Rings These are circular seals that provide a barrier at various joints and connections within the hydraulic system. O-rings offer versatility and are used in multiple applications due to their effective sealing properties.

4. Backup Rings Often used in conjunction with O-rings, backup rings prevent the O-rings from extruding under pressure, enhancing their functionality and lifespan.

Choosing the Right Oil Seal Kit

When selecting an oil seal kit for hydraulic cylinders, several factors should be considered

- Material Compatibility The materials used in seal manufacturing should be compatible with the hydraulic fluid to prevent degradation and failure.

- Pressure and Temperature Ratings Depending on the hydraulic system's specifications, the seals must be rated to withstand the operating pressure and temperature ranges.

- Dimensions and Fit Accurate measurements are essential to ensure that the seals fit correctly within the hydraulic cylinder, as improper fitting can lead to leaks and system failure.

Conclusion

Hydraulic cylinder oil seal kits are indispensable components in ensuring the effectiveness and longevity of hydraulic systems. By preventing leaks, protecting against contamination, and maintaining pressure, these kits contribute significantly to the durability and efficiency of hydraulic cylinders. For industries relying on hydraulic power, investing in high-quality oil seal kits is not just a maintenance task but a critical strategy for sustained operational success. In an ever-evolving industrial landscape, choosing the right seal kit can make all the difference in achieving optimal performance and reliability in hydraulic applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories