ພ.ຈ. . 20, 2024 04:02 Back to list

high temperature oil seal

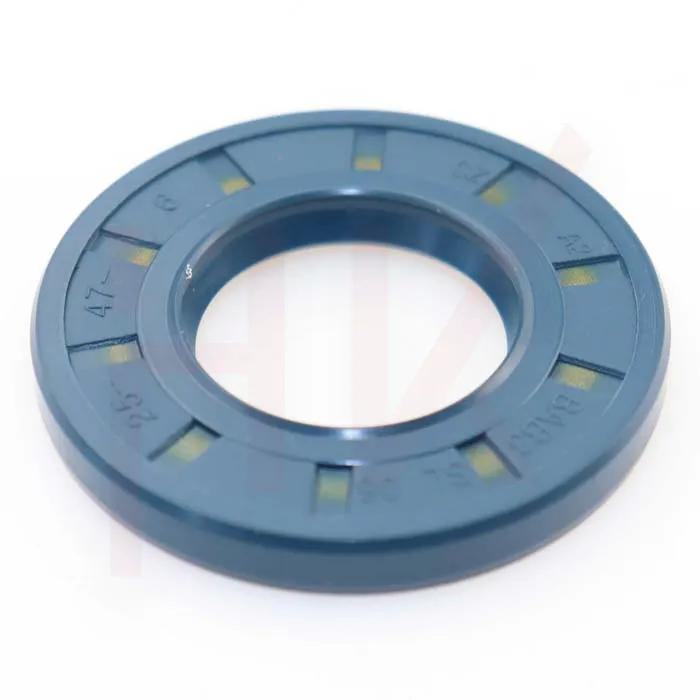

High Temperature Oil Seals Essential Components for Industrial Applications

In the realm of mechanical engineering and industrial applications, high temperature oil seals play a crucial role in maintaining the efficiency and longevity of machinery. As the demand for high-performance equipment increases across various industries—such as automotive, aerospace, and manufacturing—these seals are becoming essential components for protecting internal mechanisms from the adverse effects of heat and oil exposure.

Understanding High Temperature Oil Seals

High temperature oil seals are specifically designed to withstand extreme temperatures, typically ranging from 100°C (212°F) to over 300°C (572°F), depending on the material composition and design. These seals serve as barriers, preventing lubricants and oils from leaking out and contaminants from entering critical components like bearings, gears, and shafts. The importance of these seals cannot be overstated; they enhance the reliability and efficiency of machinery while reducing maintenance costs.

Construction and Materials

The effectiveness of high temperature oil seals is largely attributed to the materials used in their construction. Common materials include fluorocarbon elastomers (FKM), silicone, and polyacrylate, each chosen for their specific temperature and chemical resistance properties. For instance, FKM seals exhibit excellent thermal stability and resistance to various oils, making them ideal for applications that involve both high temperatures and aggressive lubricants.

The design also plays a significant role in the performance of these seals. Many high temperature oil seals feature a robust lip design that ensures optimum contact with the shaft, preventing leaks while reducing friction. Some designs may also incorporate spring mechanisms that help maintain seal pressure, ensuring a tighter fit even under varying operational conditions.

Applications

high temperature oil seal

High temperature oil seals are utilized in a multitude of applications across different sectors. In the automotive industry, they are found in engine components, transmissions, and differential assemblies, where they help contain lubricants while withstanding high temperatures generated by combustion processes. In the aerospace sector, these seals are critical for aircraft engines and hydraulic systems, where reliability is paramount due to the harsh flight environments.

Manufacturing processes, particularly those involving heavy machinery such as turbines and pumps, also rely on high temperature oil seals to maintain operational efficiency. These seals help to ensure that lubricants remain inside the system, thereby reducing wear on moving parts and extending the lifespan of equipment.

Importance of Maintenance

While high temperature oil seals are designed to be durable and long-lasting, regular maintenance is essential for ensuring their continued effectiveness. Over time, exposure to high temperatures, chemicals, and mechanical stress can cause seals to degrade, leading to potential failures. Operators should routinely inspect seals for signs of wear, such as cracking, hardening, or distortion, and replace them as necessary to prevent unexpected downtimes and costly repairs.

Future Trends

As industries continue to evolve, the demand for high temperature oil seals is expected to grow. Advances in material science are paving the way for the development of even more resilient seals that can withstand extreme conditions while offering better performance. For instance, the integration of nanomaterials and advanced elastomers may enhance the thermal and chemical resistance of oil seals, allowing them to operate in more demanding environments.

Conclusion

High temperature oil seals are vital components in the functioning of modern machinery, providing essential protection against oil leakage and contamination. Their ability to withstand extreme conditions makes them indispensable in numerous sectors, including automotive, aerospace, and manufacturing. By understanding their construction, applications, and importance in maintenance, industries can better appreciate the role these seals play in preserving efficiency and reliability. As technology progresses, the future of high temperature oil seals looks promising, with innovations that will further enhance their performance and applicability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories