ພ.ຈ. . 14, 2024 11:43 Back to list

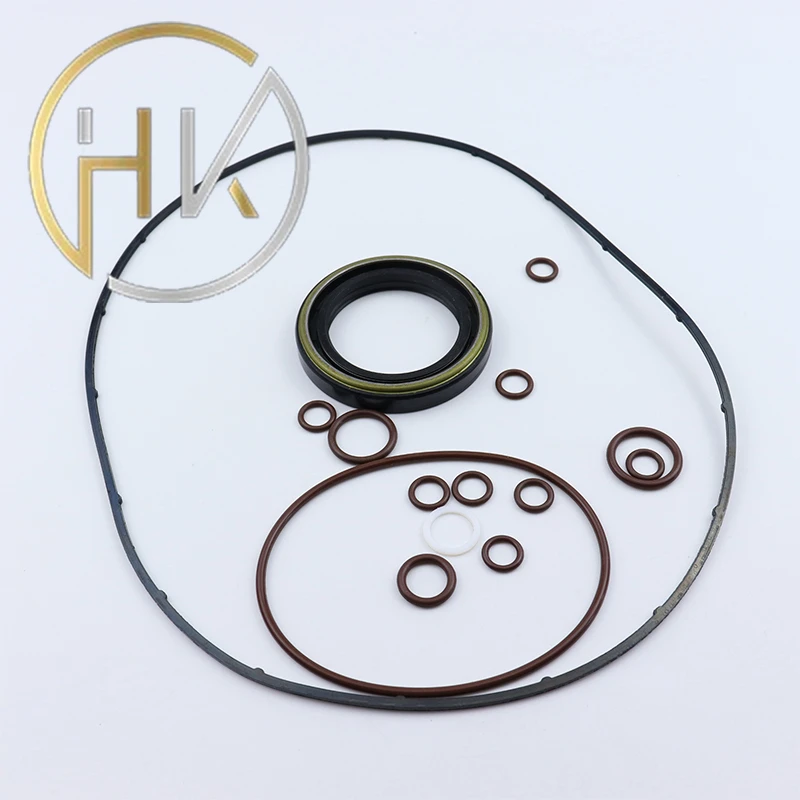

high pressure rotary seal

High Pressure Rotary Seals An Overview

High-pressure rotary seals play a critical role in numerous industrial applications by preventing leakage between rotating and stationary components. Their functionality is essential in a variety of machines, including pumps, turbines, compressors, and other mechanical systems. As industries strive for increased efficiency and reliability, the importance of high-pressure rotary seals becomes more pronounced.

Understanding High-Pressure Rotary Seals

A high-pressure rotary seal consists of two primary components a rotating part and a stationary part. The rotating component typically presents a shaft or spindle, while the stationary component is an outer casing or housing. The seal’s primary purpose is to maintain a barrier that prevents the escape of fluids or gases from the system while enabling the rotation of the shaft.

To achieve effective sealing, these rotary seals are designed with materials that can withstand extreme pressure and temperature conditions. Common materials used include elastomers, PTFE (polytetrafluoroethylene), and metal. The choice of materials often depends on the specific application, including the type of fluids being sealed, the pressure range, and the operational temperature.

Key Applications

High-pressure rotary seals are utilized across various sectors, including

1. Oil and Gas Industry In exploration and production, rotary seals are crucial for downhole equipment and drilling systems, where they face harsh environmental conditions and high pressures.

2. Aerospace Seals are integral to jet engines and other aircraft systems, ensuring that fuel and hydraulic oils remain contained while withstanding extreme pressure differentials.

3. Hydraulic Systems High-pressure rotary seals are essential in hydraulic pumps and motors, where they facilitate the transfer of hydraulic fluids under considerable pressure.

high pressure rotary seal

Design Considerations

When designing high-pressure rotary seals, several factors must be considered

- Pressure Tolerance The seal must be designed to handle the maximum pressure of the application without failure. Engineers often conduct simulations and tests to validate the seal’s performance under various pressure scenarios.

- Temperature Range High-pressure environments often correlate with elevated temperatures. The materials used must maintain their integrity and sealing capabilities at both high and low temperatures to avoid premature wear and tear.

- Rapidity of Rotation The velocity at which the shaft rotates affects the efficiency of the seal. High-speed applications may require seals that can minimize friction and wear.

- Fluid Compatibility The seal material should be compatible with the fluids it will encounter, preventing degradation or failure that could lead to leaks.

Maintenance and Longevity

To maximize the lifespan of high-pressure rotary seals, regular maintenance is essential. This includes monitoring operational conditions, inspecting the seals for wear and tear, and replacing them when necessary. In many cases, implementing proper lubrication strategies can also help extend the life of the seals, reducing friction and preventing overheating.

Conclusion

High-pressure rotary seals are vital components in ensuring the reliability and efficiency of various industrial systems. Their ability to withstand extreme conditions makes them indispensable, particularly in applications prone to high pressures and temperatures. As technology advances, the development of new materials and designs will further enhance the performance of rotary seals, catering to the increasingly demanding requirements of modern industries. Proper focus on design considerations, combined with regular maintenance, will ensure that these critical components continue to operate effectively, ultimately contributing to increased productivity and reduced downtime in industrial operations.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories