ພ.ຈ. . 25, 2024 01:50 Back to list

22x35x7mm Oil Seal Specifications and Applications for Mechanical Engineering

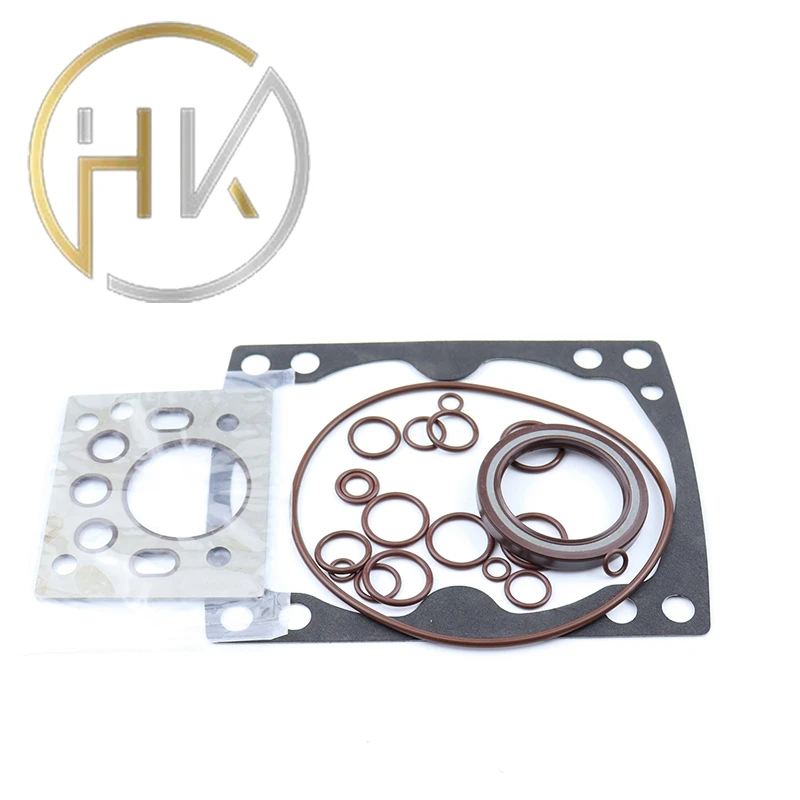

Understanding the 22x35x7 Oil Seal A Comprehensive Overview

Oil seals are critical components in various machinery and automotive applications. Among the many different sizes and types, the 22x35x7 oil seal stands out due to its specific dimensions and versatility. In this article, we will explore what an oil seal is, the importance of the 22x35x7 size, its applications, and maintenance tips to ensure longevity.

What is an Oil Seal?

An oil seal, also known as a fluid seal or grease seal, is a device that seals the interface between two components, preventing the escape of lubricants and the ingress of contaminants. Typically made from materials like rubber or polymer, oil seals are designed to withstand specific conditions, including temperature variations, chemical exposure, and pressure changes. They play a crucial role in maintaining the efficiency and lifespan of machinery by ensuring that lubricants remain where they are needed.

Dimensions Explained 22x35x7

The numbers in the designation 22x35x7 refer to the measurements of the oil seal in millimeters

- 22 mm The inner diameter (ID) of the seal, which means it fits onto a shaft or other circular component that measures 22 mm in diameter. - 35 mm The outer diameter (OD) of the seal, indicating that it fits into a housing or bore that measures 35 mm in diameter. - 7 mm The thickness (width) of the seal, which helps determine how much space it will occupy and how robust it is.

Understanding these dimensions is crucial for ensuring a proper fit and optimal performance in applications.

Applications of the 22x35x7 Oil Seal

The 22x35x7 oil seal is widely used in various industries, including automotive, manufacturing, and construction

. Some of the common applications include1. Automotive Systems This oil seal is frequently found in engines, transmissions, and differentials. It helps contain the oil, preventing leaks and ensuring that the moving parts are adequately lubricated.

2. Heavy Machinery In construction and agricultural equipment, the 22x35x7 oil seal is vital for maintaining hydraulic systems, where oil leakage can lead to catastrophic failures.

3. Industrial Equipment Many manufacturing machines also utilize this type of oil seal to ensure they operate smoothly and avoid costly downtimes due to fluid leaks.

22x35x7 oil seal

4. Electronics In certain electronic devices, small oil seals may help protect sensitive components from dust and moisture while ensuring lubrication is maintained where necessary.

Material Considerations

The choice of material for oil seals is critical to their performance. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone. Each of these materials has unique properties suited for different operating environments

- Nitrile Rubber (NBR) Excellent for general oil resistance and is often used in automotive applications. - Fluorocarbon Rubber (FKM) Offers superior resistance to chemicals and high temperatures, making it suitable for harsh environments. - Silicone Provides good temperature resistance and flexibility but has limited oil resistance, making it more suitable for specific applications.

Maintenance Tips

To ensure the longevity of a 22x35x7 oil seal, consider the following maintenance tips

1. Regular Inspections Periodically check for signs of wear or damage. Look for oil leaks around the seal, which can indicate that it may need to be replaced.

2. Proper Installation Ensure that the oil seal is installed correctly. Misalignment can lead to premature wear and failure.

3. Appropriate Lubricants Use lubricants that are compatible with the oil seal material to avoid degradation.

4. Environmental Considerations Protect the seal from exposure to extreme conditions, such as excessive heat, heavy vibrations, or aggressive chemicals, which can compromise its integrity.

Conclusion

The 22x35x7 oil seal is an essential component in various mechanical applications. Understanding its specifications, applications, and maintenance can significantly impact the efficiency and reliability of the equipment in which it is used. By incorporating best practices for installation and maintenance, users can ensure optimal performance and extend the service life of mechanical systems that rely on oil seals.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories