Dec . 10, 2024 20:46 Back to list

Suppliers for High-Quality Lip Seal Products and Solutions

The Importance of Selecting Quality Lip Seal Suppliers

In the manufacturing and engineering industries, the integrity of machinery and equipment is paramount. One critical component that ensures the effective performance and longevity of these systems is the lip seal. Lip seals, also known as radial shaft seals, are used to prevent the leakage of fluids, keep contaminants out, and maintain the proper functioning of rotary components. Therefore, selecting the right lip seal suppliers can significantly impact your operations. This article will discuss the importance of choosing quality lip seal suppliers and the factors to consider in your selection process.

Understanding Lip Seals

Lip seals are designed to create a barrier between rotating shafts and the environment. They are commonly used in various applications, including automotive, aerospace, and industrial machinery. The seal consists of a rubber or elastomeric lip that makes contact with the shaft, along with a rigid outer casing that fits into the housing. The effectiveness of a lip seal depends on its material, design, and manufacturing precision. This makes it imperative to source these components from reputable suppliers.

The Role of Quality Suppliers

When it comes to lip seals, quality suppliers provide several advantages. First and foremost, they ensure that the seals meet international standards and specifications. Poor quality seals can lead to excessive wear, leaks, and equipment failure, resulting in costly downtime and repairs. Quality suppliers conduct rigorous testing and quality control measures to ensure their products will perform reliably.

Additionally, leading lip seal suppliers often have a wealth of experience in the industry. They understand the intricacies of seal design and material selection. This expertise allows them to offer tailored solutions that match the specific needs of your applications. Whether you require seals for high-temperature, high-pressure, or corrosive environments, a reputable supplier can help you find the right product.

Factors to Consider When Choosing Lip Seal Suppliers

1. Product Range Look for suppliers that offer a comprehensive range of lip seals. This can include different materials, sizes, and designs to cater to various applications. A diverse product range indicates that the supplier is capable of meeting specific requirements.

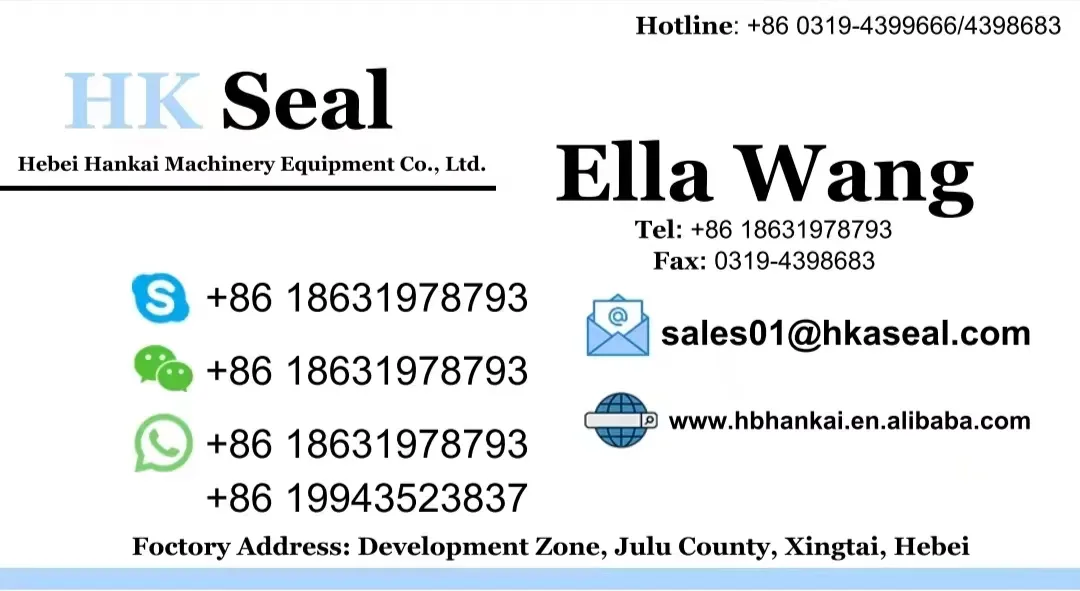

lip seal suppliers

2. Quality Assurance Check if the supplier follows strict quality control protocols. Certifications such as ISO 9001 can be a good indicator of a supplier's commitment to quality. Ensure that they provide testing results and documentation for their products.

3. Customization Options Sometimes, standard seals do not meet your exact needs. A good supplier should be able to offer customization options, allowing you to specify dimensions, materials, and design features.

4. Industry Experience Consider the supplier’s experience in the industry. Suppliers with a long history often have a better understanding of market demands and can provide valuable insights into best practices.

5. Customer Support Evaluate the level of customer support provided. A reliable supplier should offer technical assistance, timely responses to inquiries, and support throughout the purchasing process.

6. Reputation and Reviews Research the supplier's reputation by reading reviews, testimonials, and case studies from other clients. A reputable supplier will have positive feedback regarding their product quality and service.

7. Logistics and Delivery Finally, consider the supplier's logistics capabilities. Timely delivery is crucial for maintaining production schedules. Ensure that the supplier can meet your demands in terms of lead times and shipping.

Conclusion

Selecting the right lip seal supplier is essential for ensuring the reliability and efficiency of your equipment. With the right partner, you can enhance the performance of your systems, reduce maintenance costs, and improve overall productivity. By considering factors such as product range, quality assurance, customization options, and customer support, you can make an informed decision that aligns with your operational needs. Investing time in finding a quality lip seal supplier is an investment in the success and longevity of your machinery.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories