Nov . 10, 2024 11:17 Back to list

Understanding Hydraulic Pump Seals for Optimal Performance and Longevity in Fluid Systems

Understanding Hydraulic Pump Seals Importance, Types, and Maintenance

Hydraulic pumps are essential components in various industrial systems, facilitating the transfer of fluid to generate force and operate machinery. One critical aspect of hydraulic pumps is their seals, which play a vital role in maintaining efficiency and preventing leaks. This article delves into the importance of hydraulic pump seals, the different types available, and the best practices for maintenance.

Importance of Hydraulic Pump Seals

Hydraulic pump seals serve several critical functions. Primarily, they prevent the leakage of hydraulic fluid, which is crucial for the smooth operation of the hydraulic system. Fluid leaks not only waste resources but can also lead to reduced efficiency and potential damage to the pump and other components. Furthermore, leaks can pose safety hazards, creating slippery surfaces and environmental concerns.

Moreover, hydraulic seals maintain the necessary pressure within the system. This pressure is essential for the proper functioning of hydraulic systems, as it enables the transfer of energy to perform work. Inadequate sealing can lead to pressure drops, compromising the system's performance.

Additionally, hydraulic seals provide contamination control. By preventing the ingress of dirt, dust, and other contaminants, seals help preserve the integrity of the hydraulic fluid and the components within the pump. Contaminants can accelerate wear and tear, leading to premature failure and costly repairs.

Types of Hydraulic Pump Seals

There are several types of hydraulic pump seals, each designed for specific applications and environments

1. O-Rings O-rings are circular seals that fit into a groove and provide a tight seal when compressed. They are commonly used in low-pressure applications but can also be found in some high-pressure environments.

2. U-Cups U-cup seals are shaped like a U and are ideal for sealing applications where there is a bidirectional pressure. They are often made of elastomeric materials and are commonly used in pistons and rods.

3. V-Packing V-packing seals consist of multiple V-shaped rings stacked together. They are particularly effective in high-pressure applications and are often utilized in hydraulic cylinders.

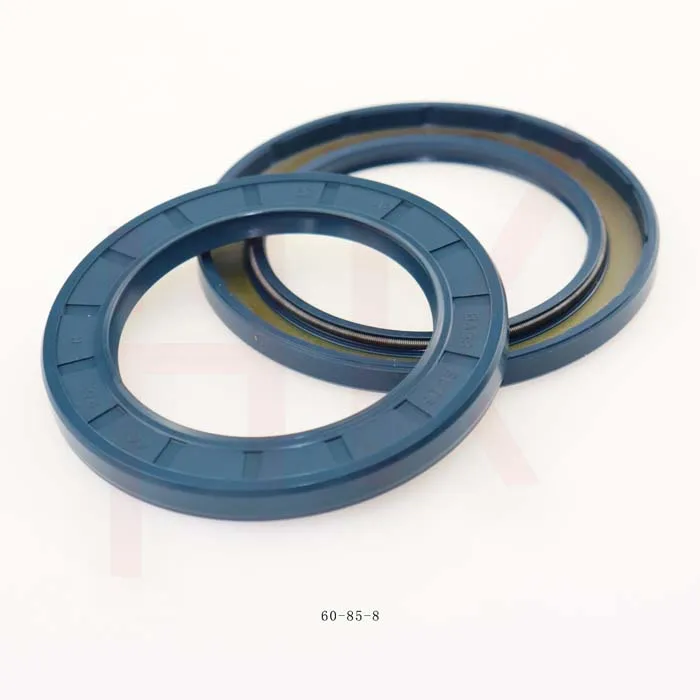

hydraulic pump seals

4. Lip Seals Lip seals, or contact seals, provide a tight seal against the rod or shaft. They have a flexible lip that makes contact with the surface, preventing fluid leaks and keeping contaminants out.

5. Composite Seals These seals are made from a combination of materials to enhance performance, often used in specialized applications where traditional seals might fail.

Maintenance of Hydraulic Pump Seals

To ensure the longevity and effectiveness of hydraulic pump seals, regular maintenance is essential. Here are some best practices

- Regular Inspection Routinely inspect seals for signs of wear, damage, or leakage. Early detection can prevent more severe issues and costly repairs down the line.

- Fluid Compatibility Ensure that the hydraulic fluid used is compatible with the seal materials. Incompatible fluids can lead to seal degradation and failure.

- Proper Installation When installing new seals, follow manufacturer guidelines. Incorrect installation can cause premature failure, leaks, and system malfunctions.

- Monitor Operating Conditions Keep an eye on temperature and pressure levels within the hydraulic system. Extreme conditions can negatively impact seal performance and longevity.

- Replace Worn Seals Don’t delay the replacement of seals that show significant wear or damage. Allowing worn seals to remain in service can lead to system inefficiencies and failures.

Conclusion

Hydraulic pump seals are indispensable for maintaining the efficiency and reliability of hydraulic systems. Understanding the various types of seals and implementing proper maintenance practices can help optimize performance and reduce downtime. By prioritizing the integrity of seals within hydraulic pumps, industries can ensure smoother operations, increased safety, and extended equipment lifespan.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories