تشرینی دووەم . 20, 2024 14:42 Back to list

hydraulic cylinder kits repair

Understanding Hydraulic Cylinder Kits Repair A Comprehensive Guide

Hydraulic systems are integral to the operation of various machinery across multiple industries, from construction to manufacturing. At the heart of these systems are hydraulic cylinders, which convert fluid pressure into mechanical force. Over time, wear and tear can lead to the need for repair, and that is where hydraulic cylinder kits come into play. This article aims to shed light on the essential components of hydraulic cylinder kits and the repair process, ensuring that you can keep your machinery running smoothly.

What Are Hydraulic Cylinder Kits?

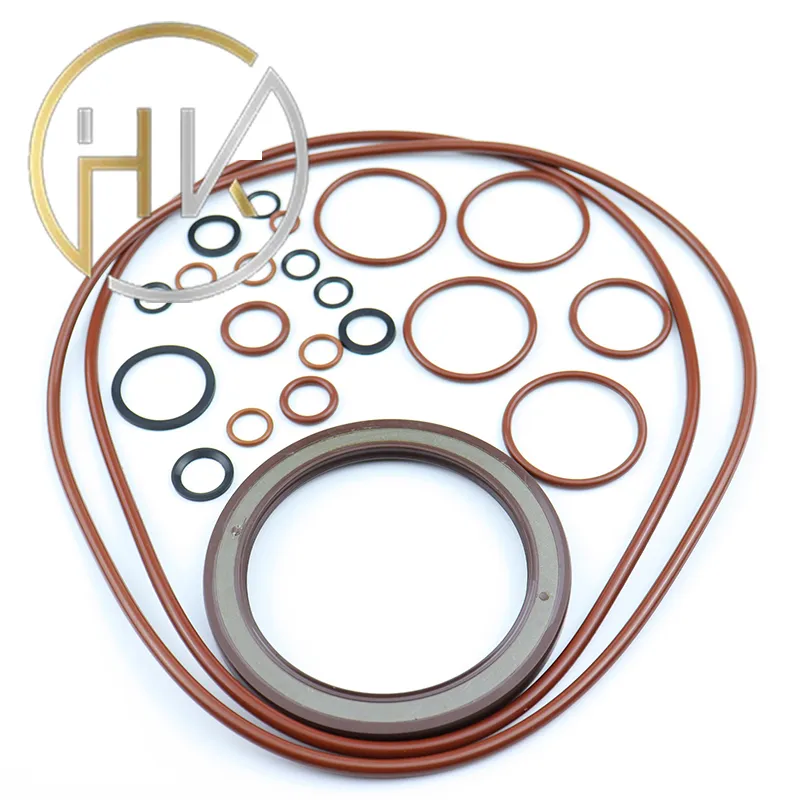

Hydraulic cylinder kits typically include all the necessary components required to repair or rebuild a hydraulic cylinder. These kits generally consist of seals, O-rings, piston rings, wear rings, and other essential components critical to restoring the functionality of the hydraulic cylinder. Availability of these kits allows for a comprehensive repair approach, enhancing machine performance and prolonging the life of the equipment.

Importance of Timely Repairs

Delaying repairs on hydraulic cylinders can lead to more significant issues down the line, such as decreased efficiency, increased energy consumption, or even complete system failure. Common symptoms that may indicate the need for repairs include leaks, decreased performance, and unusual noises during operation. Addressing these issues promptly not only saves money in the long run but also ensures the safety of operators and integrity of the machinery.

The Repair Process

1. Disassembly The first step in the repair process is disassembling the hydraulic cylinder. This involves safely removing it from the equipment and taking it apart to access its internal components.

2. Inspection A thorough inspection is crucial. Look for signs of wear, damage, or scoring on the piston rod and cylinder bore. Use specialized tools to measure the dimensions, ensuring there are no discrepancies that may affect the cylinder's performance.

hydraulic cylinder kits repair

3. Cleaning Clean all components to remove dirt, old seals, and any debris. This step is essential, as contaminants can lead to premature failure of new seals and components.

4. Replacing Components With a hydraulic cylinder kit at hand, replace all necessary components. This includes installing new seals, O-rings, and any other worn or damaged parts. Pay close attention to the arrangement and orientation of the seals to prevent leaks.

5. Reassembly Once everything is replaced, carefully reassemble the hydraulic cylinder. Make sure to tighten all bolts and fittings to the manufacturer's specifications to ensure a secure fit.

6. Testing Finally, the repaired hydraulic cylinder should be tested. Reinstall it in the machinery and run the system under normal operating conditions to ensure that it functions correctly without leaks or performance issues.

Selecting the Right Hydraulic Cylinder Kit

When choosing a hydraulic cylinder kit for repair, ensure you select one that matches the specifications of your existing cylinder. Compatibility is critical for an effective repair. Always opt for high-quality kits from reputable manufacturers to ensure reliability and durability.

Conclusion

Maintaining hydraulic cylinders through proper repair and the use of quality hydraulic cylinder kits is vital for the longevity of your machinery. Timely repairs can prevent minor issues from escalating into larger, more costly problems, safeguarding your equipment's performance and your investment. Whether you are a technician, a supervisor, or a hands-on operator, understanding the components and process of hydraulic cylinder repair will empower you to keep your systems in optimal working order. By investing time and resources into maintenance, you ensure efficiency and productivity in your operations, ultimately contributing to the success of your enterprise.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories