کانونی یەکەم . 29, 2024 15:37 Back to list

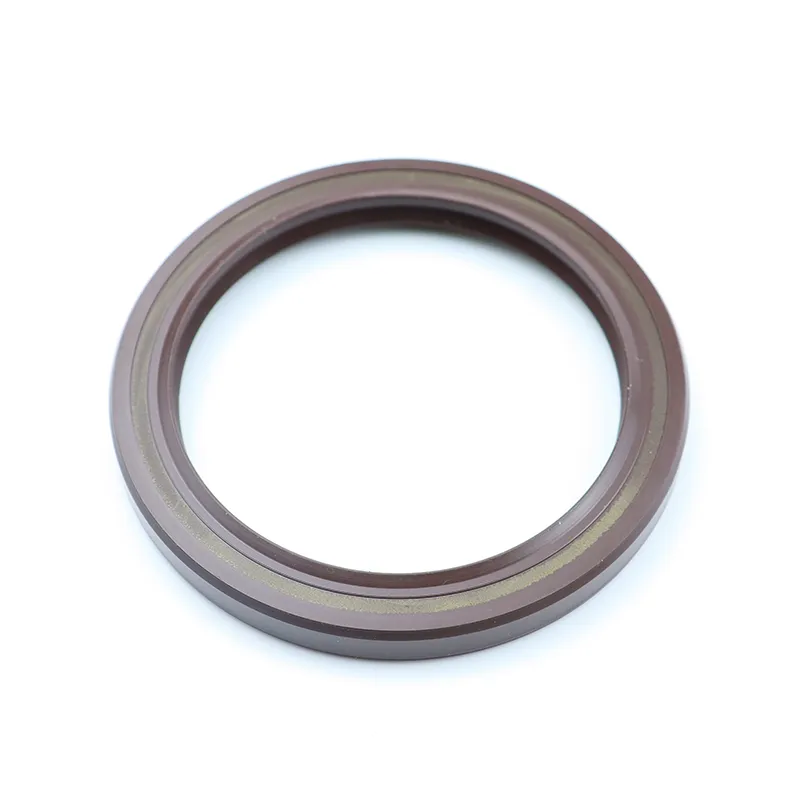

55 80 10 oil seal

Understanding the Importance of Oil Seals A Focus on 55%, 80%, and 10% Specifications

Oil seals play a crucial role in the functioning and longevity of machinery and equipment across various industries. These components are designed to prevent the leakage of lubricants and other fluids, ensuring optimal performance and efficiency. In discussing oil seals, the percentages 55%, 80%, and 10% often refer to the materials used, their applications, or specific characteristics that influence their performance. In this article, we will explore these percentages and their significance in the realm of oil seals.

The Role of Oil Seals

Oil seals, also known as rotary shaft seals, are essential in numerous applications, including automotive engines, manufacturing machinery, and household appliances. Their primary function is to create a barrier that prevents oil, grease, or other fluids from escaping while also protecting the internal components from contaminants like dust and dirt. This sealing process is vital for maintaining the integrity of mechanical systems and ensuring that they operate smoothly and efficiently.

Understanding the Percentages

1. 55% - Material Composition The 55% designation often refers to the material composition of oil seals. Many oil seals are made using elastomers, which provide elasticity and resistance to wear and tear. A seal with 55% specified material composition might indicate a formulation that balances the rubber's hardness and flexibility. This composition is crucial because it affects the seal's ability to withstand varying temperatures and pressures. A well-balanced elastomeric seal can effectively accommodate the dynamic movements of rotating shafts while maintaining its integrity over time.

2. 80% - Performance Efficiency

The 80% figure typically indicates the performance efficiency of the oil seal. This can relate to its ability to prevent leakage and resist the effects of heat and chemical exposure. An oil seal rated at 80% would generally be understood to provide high-quality sealing capabilities, reducing the chances of fluid loss and minimizing maintenance downtime. Industries often opt for seals with higher performance ratings to ensure that machinery operates optimally, as even minor leaks can lead to significant operational issues and increased costs.

55 80 10 oil seal

3. 10% - Application Specificity

Finally, the 10% specification often pertains to the application-specific characteristics of the oil seal. Different machinery and environments require oil seals with varying properties, such as temperature resistance, chemical compatibility, and pressure tolerance. A seal designed for high-pressure environments might only meet 10% of the standard specifications for normal operations but is perfectly tailored for its intended application. Understanding these specific requirements is essential for selecting the right oil seal for a particular job.

Choosing the Right Oil Seal

When selecting an oil seal, it is vital to consider not only the material composition but also the performance ratings and application-specific requirements. Factors like operating conditions, fluid types, and environmental considerations can significantly influence the seal's longevity and effectiveness. For instance, in high-temperature environments, a seal made with suitable thermal resistance materials (like a 55% silicone compound) could be critical. Conversely, in chemical-rich environments, a seal with excellent chemical compatibility (potentially rated closer to the 80% mark) might be necessary.

Conclusion

Oil seals are indispensable components in many mechanical systems, with their effectiveness directly influencing the performance and longevity of equipment. Understanding the significance behind the 55%, 80%, and 10% specifications can guide industries in making informed decisions about which seals to use for their specific applications. As technology advances and industries evolve, the importance of selecting the right oil seal continues to grow, ultimately contributing to enhanced operational efficiency and reduced maintenance costs.

Investing in quality oil seals is not merely a choice but a necessity for any business aiming to maintain high performance and reliability in its machinery.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories