تشرینی یەکەم . 13, 2024 03:38 Back to list

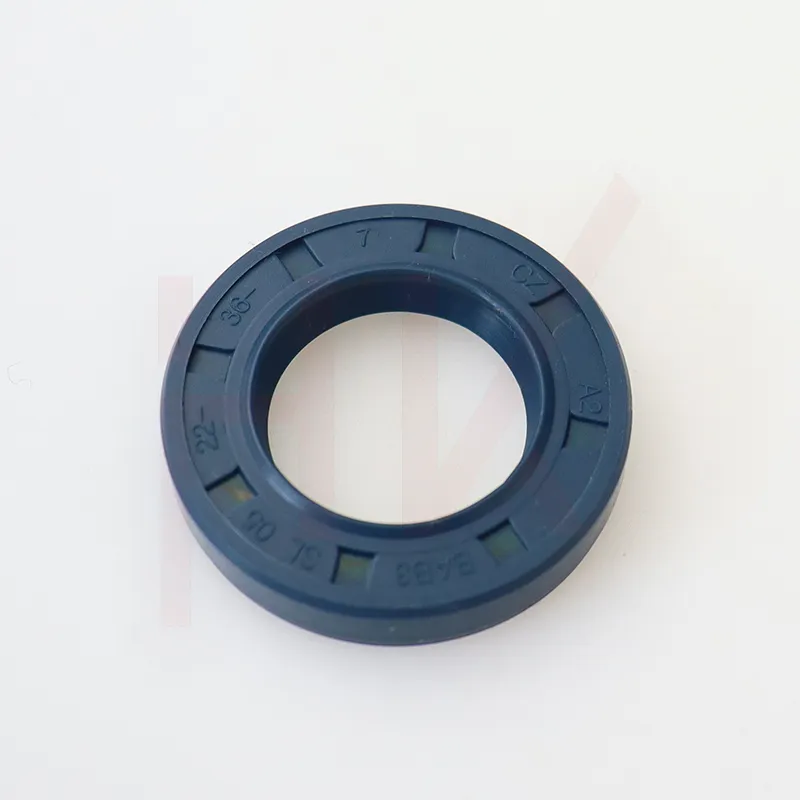

35 52 7 oil seal

Understanding the 35% 2052 7 Oil Seal Importance, Application, and Maintenance

Oil seals are critical components in many machines and mechanical systems, tasked with preventing the leakage of lubricants and protecting internal components from contaminants. Among the diverse range of oil seals available, the 35% 2052 7 oil seal stands out for its specific applications and properties. This article delves into the significance of this oil seal, its common uses, and maintenance tips to ensure optimal performance.

What is a 35% 2052 7 Oil Seal?

The designation 35% 2052 7 refers to specific dimensions and materials used in manufacturing this oil seal. The numbers typically indicate the inner diameter (35 mm), outer diameter (52 mm), and thickness (7 mm), which means it is designed to fit in corresponding housings and shafts. The material composition is equally important, as oil seals can be manufactured from rubber, polyurethane, and other non-metallic materials, selected based on the operational environment and fluid type.

Importance of Oil Seals

Oil seals serve multiple functions, making them indispensable in various applications. Primarily, they play a crucial role in

1. Leak Prevention Oil seals create a barrier that prevents lubricants from escaping from the machinery. This is vital for maintaining optimal lubrication, which contributes to the overall efficiency and longevity of the equipment.

2. Contaminant Protection Besides retaining lubricants, oil seals protect internal components from dust, dirt, water, and other contaminants that could lead to wear and malfunction.

3. Efficiency and Performance By ensuring that the lubrication remains intact, oil seals help maintain the performance of machinery. A well-functioning oil seal can reduce energy consumption and increase operational reliability by minimizing friction.

Common Applications

The 35% 2052 7 oil seal is widely used in various industries, including automotive, industrial machinery, and agricultural equipment

. Some specific applications include- Automobile Engines In vehicles, this oil seal might be used around crankshafts or camshafts to prevent oil leaks, thereby maintaining engine efficiency and performance.

- Hydraulic Systems Hydraulic machinery relies heavily on oil seals to contain hydraulic fluid, ensuring that the system operates smoothly without leaks.

- Pumps and Compressors These machines often incorporate oil seals to prevent fluid loss and protect internal components from contamination, thereby enhancing their operational lifespan.

35 52 7 oil seal

Choosing the Right Oil Seal

Selecting the appropriate oil seal is crucial for ensuring compatibility with the application. Factors to consider include

- Material Depending on the operating temperature, chemical exposure, and type of lubricant (oil or grease), the material of the oil seal should be chosen wisely to ensure durability.

- Size The dimensions of the oil seal must match those of the housing and shaft to provide an effective seal.

- Application Requirements Specific applications may require oil seals with enhanced features, such as specific resistance to heat or chemicals, which should be viewed when making a choice.

Maintenance Tips

Proper maintenance of oil seals is essential for extending their lifespan and ensuring the machinery's reliability. Here are some tips

1. Regular Inspections Regularly check for signs of wear, such as leaks or visible damage to the oil seal. Prompt replacement can prevent further damage.

2. Correct Installation Ensure proper installation of the oil seal, paying attention to alignment and avoiding excessive force, which could deform the seal and lead to premature failure.

3. Environmental Control Protect the seal from harsh environmental conditions or chemical exposure, as these factors can degrade the materials over time.

4. Use Manufacturer Recommendations Follow guidelines from the manufacturer regarding maintenance schedules and replacement intervals to keep equipment in peak condition.

Conclusion

The 35% 2052 7 oil seal is an essential component in various machinery, providing reliable sealing solutions for preventing leaks and protecting against contaminants. Understanding its importance, applications, and maintenance tips can help users maximize the efficiency and lifespan of their equipment. As technology advances, innovations in oil seal design and materials will continue to enhance their performance and reliability in demanding environments.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories