10월 . 07, 2024 12:22 Back to list

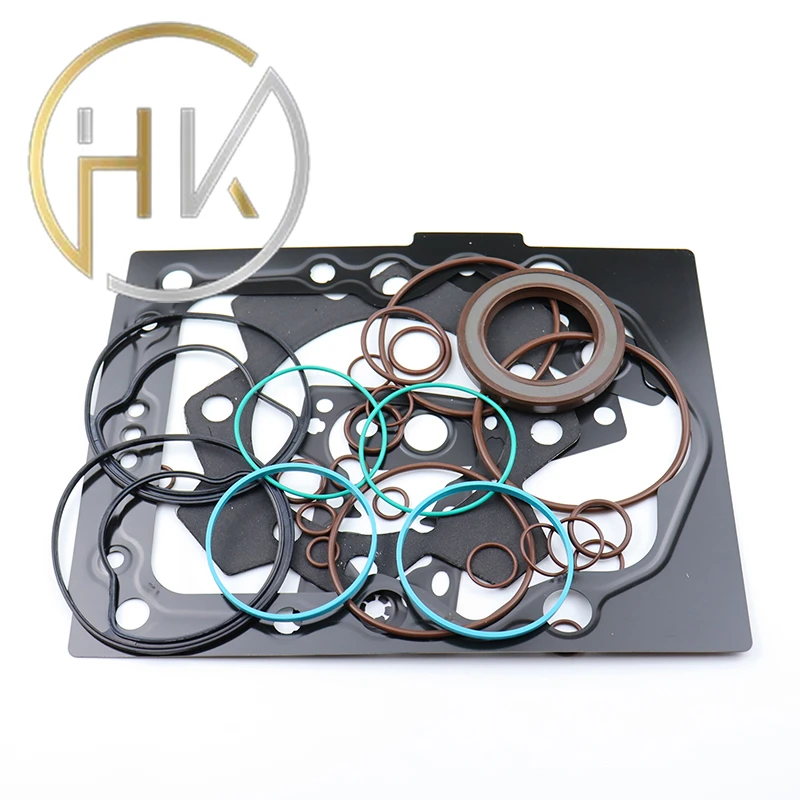

hydraulic motor seal kit

Understanding Hydraulic Motor Seal Kits Essential Components for Optimal Performance

Hydraulic motors are widely used in various industries, including construction, manufacturing, and agriculture, due to their efficiency and ability to convert hydraulic energy into mechanical power. However, like any mechanical equipment, they require regular maintenance to ensure optimal performance and longevity. One critical aspect of this maintenance is the use of hydraulic motor seal kits, which play a vital role in preventing leaks and maintaining the integrity of the system.

A hydraulic motor seal kit typically contains a collection of seals, O-rings, and other components designed specifically for a particular model of hydraulic motor. These seals are essential in preventing hydraulic fluid from leaking out of the motor during operation, which can lead to decreased efficiency, increased wear and tear, and potential damage to other components. Moreover, leaks can pose safety hazards, as hydraulic fluid is often under high pressure and can cause slips or environmental hazards if not contained.

The primary function of the seals within the kit is to create a tight barrier between moving parts and the external environment. Over time, seals can degrade due to various factors, including heat, pressure, and exposure to chemicals. Regular inspection and replacement of these seals are crucial to ensuring that the hydraulic motor remains in good operating condition.

hydraulic motor seal kit

When selecting a hydraulic motor seal kit, it is important to consider compatibility with the specific motor model. Different motors may require different seal designs and materials, so referring to the manufacturer’s specifications is essential. High-quality seal kits made from durable materials, such as polyurethane or rubber, can significantly enhance the motor’s performance and reliability.

Installation of a hydraulic motor seal kit should be carried out with care. It is advisable to follow the manufacturer’s instructions and use the appropriate tools to ensure that the seals are properly fitted. Incorrect installation can lead to premature failure of the seals and may counteract the benefits of using a seal kit.

In addition to regular maintenance and timely replacement of seal kits, operators should also monitor the performance of hydraulic motors during operation. Any signs of fluid leakage, unusual noises, or decreased performance warrant immediate attention to prevent further damage and costly repairs.

In conclusion, hydraulic motor seal kits are essential components for anyone relying on hydraulic systems. By ensuring the integrity of seals and proactively maintaining equipment, operators can enhance the efficiency, safety, and lifespan of hydraulic motors. Whether in heavy machinery or industrial applications, investing in quality seal kits and adhering to a regular maintenance schedule is key to achieving optimal performance in hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories