1월 . 20, 2025 15:19 Back to list

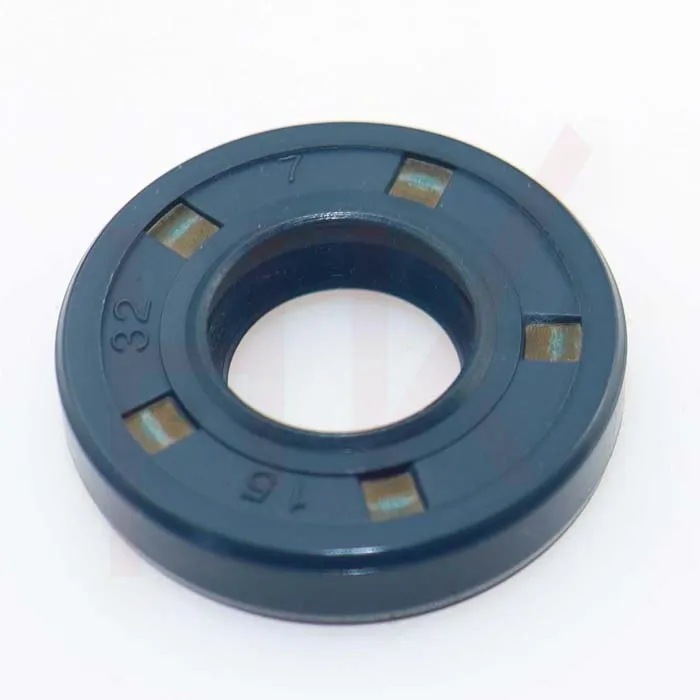

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

3. Cylinder Breakdown Once detached, drain the hydraulic fluid and proceed to remove the cylinder cap. The seal and bearing components can then be taken out. Inspect each part closely; even slight deformations indicate replacement is needed. 4. Seal Replacement Clean the groove where the new seal will sit, ensuring all dirt and residual oil are removed. Place the new seal meticulously, making sure it fits perfectly within the groove to prevent leaks. 5. Reassembly and Testing Once the new seal is in place, reassemble the cylinder and reinstall it onto the boom. Refill the hydraulic system with the recommended fluid type whenever you dismantle any hydraulic component. Start the engine and slowly cycle the hydraulic function to check for proper operation and seal efficiency. Leveraging Professional Expertise While some seasoned operators might feel comfortable undertaking a seal replacement, seeking assistance from qualified professionals can ensure precision. Expert technicians bring both experience and specialized tools to the table, diagnosing other potential issues that might be missed by an untrained eye. They also ensure that OEM (Original Equipment Manufacturer) parts are used, incrementing the longevity and performance of your excavator. Establishing Trust and Authority in Maintenance Gaining insights from reputable sources enhances your understanding and skills in maintaining heavy machinery. Manufacturers' manuals, certified training programs, and consultations with professional technicians are invaluable resources. By relying on proven methods and expert advice, operators can maintain their equipment in top condition, translating to improved efficiency and reduced unexpected downtime. Conclusively, regular maintenance and prompt replacement of components like the boom cylinder seal are paramount for the longevity and efficiency of excavators. Keeping up with these practices not only ensures the machine remains in optimal condition but also safeguards the investment and reliability of operations undertaken with these powerful machines.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories