ನವೆಂ . 24, 2024 14:14 Back to list

rotary shaft seal

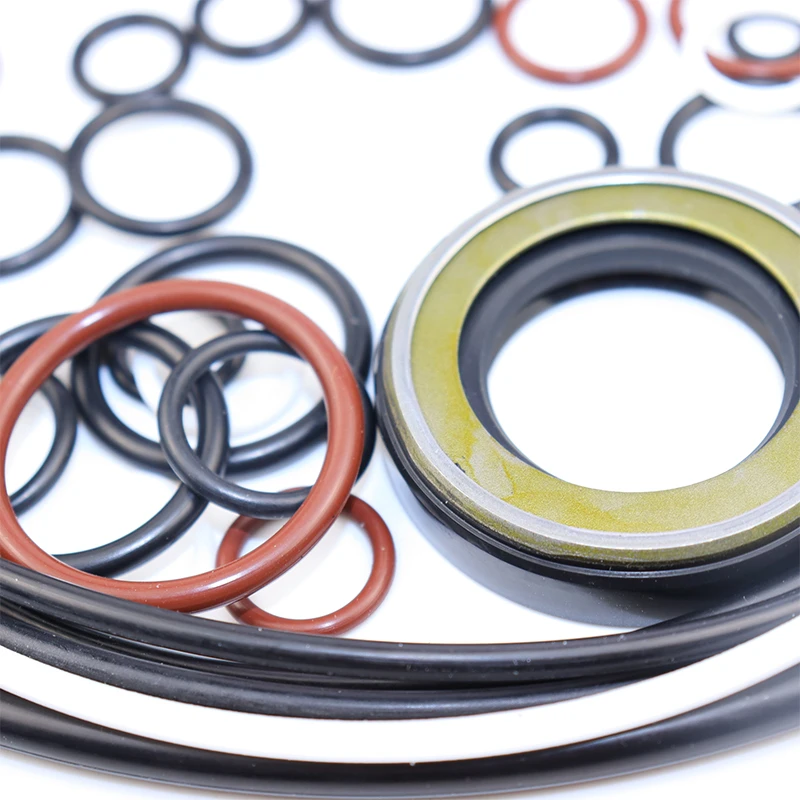

Understanding Rotary Shaft Seals Function, Design, and Applications

Rotary shaft seals, also known as lip seals or oil seals, are critical components used in various mechanical applications involving rotating shafts. These seals play a crucial role in maintaining the integrity of machinery by preventing leakage of lubricants and entry of contaminants. In this article, we will explore the function, design, and applications of rotary shaft seals.

Function of Rotary Shaft Seals

The primary function of a rotary shaft seal is to create a barrier between the rotating shaft and its housing. This barrier is essential for several reasons. Firstly, it prevents the escape of lubricants, which are vital for reducing friction and wear within moving parts. Effective lubrication extends the lifespan of the machinery and enhances its performance. Secondly, rotary shaft seals protect against the ingress of dust, dirt, water, and other contaminants that could compromise the machinery's operation. This is particularly important in environments where equipment is exposed to harsh conditions.

Design Features

Rotary shaft seals are typically made from elastomeric materials, such as nitrile rubber, fluorocarbon, or silicone. These materials are chosen for their flexibility and resilience, allowing them to maintain a tight seal while accommodating slight variations in shaft movement. The design of rotary shaft seals includes several critical features

1. Seal Lip The primary sealing component is the lip, which presses against the shaft surface. The lip design can vary based on the application needs—some may be designed for higher speeds or pressures, while others are made to withstand extreme temperatures.

2. Spring Many rotary shaft seals incorporate a garter spring that helps maintain constant pressure against the shaft. This feature ensures that the lip stays in contact with the shaft even as it wears down over time, extending the seal's life.

3. Housing The housing holds the seal in place and ensures proper alignment. It is typically designed to fit snugly with the seal, minimizing any gaps that might allow leakage or contamination.

rotary shaft seal

4. Back-Up Ring In high-pressure applications, a back-up ring may be used to prevent the seal from extrusion, enhancing the seal’s durability.

Applications

Rotary shaft seals are widely used in various industries, including automotive, aerospace, manufacturing, and oil and gas. Here are some common applications

1. Automotive In vehicles, rotary shaft seals are used in engines, transmissions, and differentials to contain lubricants and prevent leaks. They are essential for maintaining optimal performance and fuel efficiency.

2. Industrial Machinery Many industrial machines, such as pumps, motors, and gearboxes, utilize rotary shaft seals. They help ensure that machinery operates smoothly and without interruption, reducing downtime and maintenance costs.

3. Aerospace In the aerospace sector, where reliability and precision are paramount, rotary shaft seals are used in various applications, including landing gear and engine components, to prevent fluid loss and maintain system integrity.

4. Oil and Gas Exploration Rotary shaft seals are also critical in oil and gas operations, where they help maintain pressure and prevent leaks in drilling equipment and pumps.

Conclusion

Rotary shaft seals are often overlooked yet vital components in mechanical systems. They ensure that machinery operates efficiently by preventing lubricant loss and protecting against contaminants. With advancements in materials and design, rotary shaft seals continue to evolve, providing enhanced performance across various industries. Understanding their function, design, and applications allows for better maintenance practices and ultimately leads to more reliable machinery. Choosing the right seal for a specific application can significantly impact the lifespan and efficiency of equipment, underscoring the importance of these small but powerful components in engineering and manufacturing.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories