ಆಕ್ಟೋ . 10, 2024 20:31 Back to list

Understanding the Function and Benefits of Rotary Oil Seals in Mechanical Applications

Understanding Rotary Oil Seals Importance and Applications

Rotary oil seals, also known as lip seals or rotary shaft seals, play a crucial role in various mechanical systems. Primarily used to prevent fluid leaks and contamination, these seals are essential components in engines, pumps, and other machinery where rotary motion occurs. Their significance stems from their ability to maintain lubrication within a system while isolating it from external contaminants, thus ensuring longevity and optimal performance.

What is a Rotary Oil Seal?

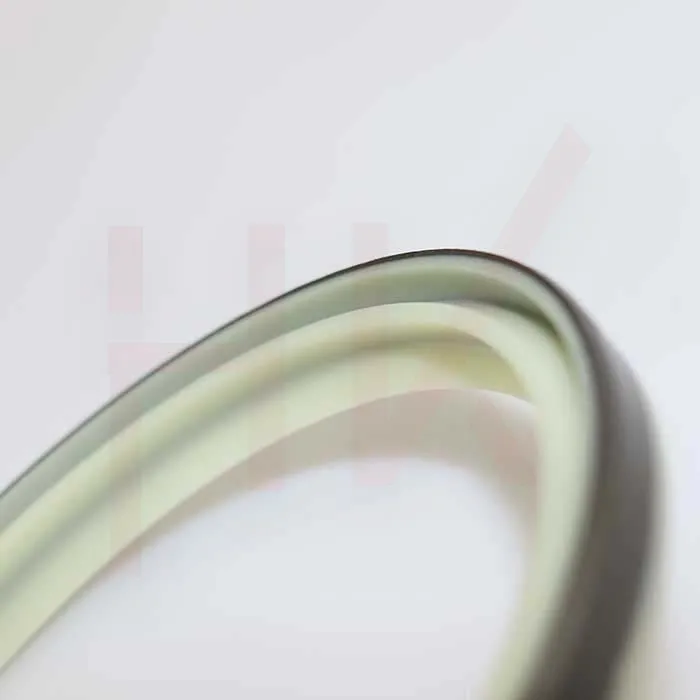

A rotary oil seal is a device typically made from elastomeric materials, such as rubber or silicone, designed to fit tightly around a rotating shaft. The seal consists of a flexible lip that makes contact with the shaft surface, creating a barrier to prevent the escape of oil and the ingress of dirt and moisture. The design of the oil seal allows it to withstand high temperatures, pressures, and the chemical action of various lubricants.

Construction and Design

Rotary oil seals are composed of several key elements the sealing lip, the body, and sometimes a spring.

1. Sealing Lip The lip is the critical component responsible for sealing. It is designed to form a tight contact with the shaft. The material and shape of the lip can vary based on the application requirements, including hardness, elasticity, and temperature resistance.

2. Seal Body The body of the seal supports the sealing lip and often features a metallic or rigid outer circumference to facilitate installation into housing. This ensures that the seal remains in place during operation.

3. Spring Some designs include a spring that provides constant pressure to the sealing lip, enhancing the performance in dynamic applications where the shaft may experience vibrations or shifts.

Applications of Rotary Oil Seals

Rotary oil seals are found in numerous applications across a variety of industries

- Automotive Industry They are extensively used in engines, gearboxes, and oil pumps to prevent oil from leaking and ensure proper lubrication.

rotary oil seals

- Industrial Machinery In manufacturing equipment, rotary seals help maintain the integrity of hydraulic systems and other machinery components by keeping lubricants in and contaminants out.

- Aerospace Rotary oil seals are critical in aircraft engines and hydraulic systems where reliability is paramount, as they help to ensure smooth operation and prevent catastrophic failures.

- Marine Applications In boats and ships, rotary seals protect vital components from water ingress, thus safeguarding propulsion systems and various machinery.

Benefits of Rotary Oil Seals

Using rotary oil seals offers several advantages

1. Leak Prevention One of the primary functions of rotary seals is to prevent the leakage of lubricants, thus maintaining system efficiency.

2. Contamination Protection By keeping dirt and moisture out of critical components, they enhance the lifetime and operational reliability of machinery.

3. Cost-Effective The proper use of rotary oil seals can reduce maintenance costs by minimizing the need for frequent repairs or replacements due to leaks and contamination.

4. Versatile Design Rotary oil seals can be customized to meet specific application demands, including variations in temperature, pressure, and chemical exposure.

Conclusion

In conclusion, rotary oil seals are vital components that ensure the efficient operation and longevity of a wide range of machinery. Their ability to prevent fluid leaks while protecting against dirt and moisture makes them indispensable in many industries. Understanding the importance and functionality of these seals can lead to better maintenance practices, ultimately enhancing the reliability and performance of mechanical systems. With continued advancements in materials and design, the future of rotary oil seals looks promising, paving the way for improved efficiency in dynamic applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories