ನವೆಂ . 06, 2024 21:20 Back to list

oil seal wheel hub

Understanding Oil Seal Wheel Hubs Essential Components for Vehicle Performance

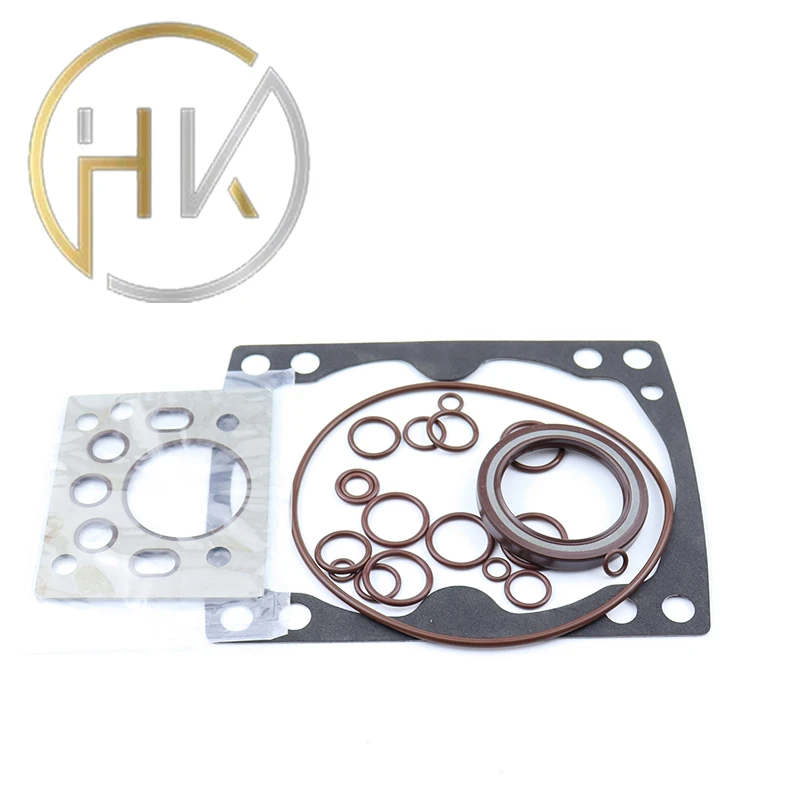

Oil seal wheel hubs play a crucial role in ensuring the efficient operation and longevity of vehicles. These components, often found in both passenger cars and commercial vehicles, help to maintain the integrity of the wheel hub assembly, which is vital for smooth driving and overall vehicle performance.

What is an Oil Seal?

An oil seal, also known as a lip seal or fluid seal, is a device used to seal rotating shafts. It prevents the leakage of lubricants like oil and grease while also keeping contaminants such as dirt and moisture out of the lubrication system. This is particularly important in a wheel hub, where the constant rotation can lead to wear over time if not properly sealed.

The Function of Oil Seal in Wheel Hubs

In a wheel hub assembly, the primary function of the oil seal is to protect the bearing and other internal components from dirt and moisture intrusion, which could lead to rust and premature wear. Additionally, it retains the grease or lubrication within the hub, reducing friction and wear on the bearings.

When driving, the wheel hub comes into contact with various elements that can compromise its integrity. Dust, water, and debris can easily enter a poorly sealed hub, causing damage. An effective oil seal ensures that these harmful elements are kept out, extending the life of the bearing and maintaining the vehicle's performance.

Types of Oil Seals

oil seal wheel hub

There are different types of oil seals used in wheel hubs, and they vary based on design and material. Common materials include rubber, silicone, and even metal. Rubber seals are widely favored for their flexibility and resilience. They can accommodate slight variations in size and shape while providing a tight seal.

Additionally, there are two types of oil seals typically found in wheel hubs single-lip and double-lip seals. Single-lip seals are simple and effective, while double-lip seals provide extra protection against contaminants, making them suitable for more demanding applications.

Importance of Regular Maintenance

Maintaining the oil seals in wheel hubs is essential for vehicle upkeep. Over time, exposure to heat, pressure, and environmental conditions can cause the seals to wear out or become brittle. Regular inspections and timely replacements can prevent costly repairs associated with bearing failures or wheel hub damage.

Drivers should be aware of symptoms indicating that oil seals may need attention, such as unusual noises coming from the wheel area, grease leakage, or decreased performance during driving. Addressing these issues promptly can enhance safety and improve the overall lifespan of the vehicle components.

Conclusion

Oil seal wheel hubs are small yet vital components of a vehicle’s wheel assembly. They safeguard the bearings, keep lubricants in place, and prevent harmful elements from causing damage. Understanding their function and importance can help vehicle owners appreciate the need for regular maintenance, ensuring a longer lifespan for their wheel hub assemblies and overall better vehicle performance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories