ಡಿಸೆ . 20, 2024 19:26 Back to list

Top Providers for High-Quality Oil Seal Solutions and Products

The Importance of Oil Seal Suppliers in Various Industries

In the realm of mechanical engineering and manufacturing, oil seals play a critical role in ensuring the optimum performance and longevity of machinery and equipment. These seals prevent the leakage of lubricants and protect components from contaminants, making them essential in a wide range of industries, including automotive, aerospace, manufacturing, and oil and gas. The significance of oil seal suppliers cannot be overstated, as they provide the necessary components that contribute to the efficiency and effectiveness of operations across these sectors.

Understanding Oil Seals

Oil seals, also known as oil glands or radial lip seals, are mechanical devices designed to retain lubricants and exclude contaminants. Typically made from elastomeric materials like rubber or thermoplastics, they feature a flexible lip that creates a tight seal against rotating shafts. This functionality helps maintain the oil's integrity, reducing friction and preventing wear and tear on machinery parts. Without effective oil seals, machinery would be prone to premature failure, increased downtime, and costly repairs.

The Role of Oil Seal Suppliers

Oil seal suppliers are integral to the supply chain for various industries. They ensure that manufacturers have access to high-quality seals that meet specific standards and requirements. The selection of appropriate seals can greatly impact the performance of machinery. Therefore, suppliers must offer a broad range of options, including different sizes, materials, and designs to cater to diverse applications.

In addition to providing products, reputable oil seal suppliers also offer valuable services, such as technical support, custom solutions, and expert advice on seal selection. This capability allows manufacturers to optimize their operations, enhancing both productivity and profitability. Suppliers with extensive knowledge of industry standards can help businesses navigate regulatory requirements, ensuring compliance and minimizing risks.

Quality Assurance and Innovation

In today's competitive landscape, quality is paramount in the manufacturing of oil seals. Reliable suppliers strive to adhere to international quality standards, using advanced materials and manufacturing processes to produce seals that perform exceptionally under varying conditions. The best suppliers conduct rigorous testing of their products, ensuring that they can withstand extreme temperatures, pressures, and chemical exposures.

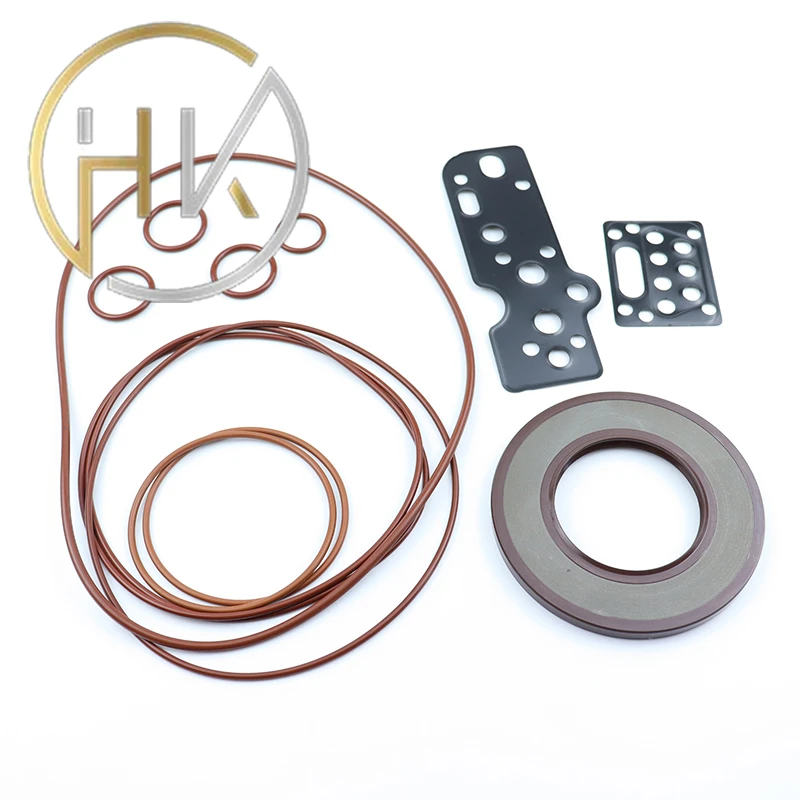

oil seal suppliers

Innovation is also a significant aspect of the oil seal industry. Suppliers are constantly exploring new materials and technologies to improve the performance of oil seals. For instance, developments in synthetic materials have led to seals that offer superior resistance to wear, chemicals, and environmental factors. This research and development ensure that industries can rely on suppliers for the latest advancements in sealing technology.

Sustainability in Oil Seal Supply

As industries increasingly focus on sustainability, oil seal suppliers are also adopting environmentally friendly practices. This includes using sustainable materials and implementing processes that minimize waste and energy consumption. Many suppliers now provide seals that are recyclable or produced from recycled materials, aligning with the global trend towards sustainable manufacturing.

Choosing the Right Oil Seal Supplier

When selecting an oil seal supplier, businesses should consider several factors. Firstly, the supplier's reputation in the industry can be an indicator of quality and reliability. Secondly, their product range should align with the specific needs of the business. Additionally, the level of customer service and support offered, including the ability to provide custom solutions, is essential for establishing a fruitful partnership.

Furthermore, considerations regarding delivery times and logistical capabilities should not be overlooked. In a fast-paced industrial environment, timely access to components can be the difference between maintaining production schedules and experiencing costly delays.

Conclusion

Oil seals are fundamental components in various machinery and equipment, and the role of oil seal suppliers extends beyond merely providing products. They are key partners in ensuring operational efficiency, product quality, and sustainability. By choosing the right supplier, businesses can enhance their performance and secure their competitiveness in the ever-evolving industrial landscape. The relationship between manufacturers and oil seal suppliers is a crucial component of long-term success in today's economy, highlighting the importance of collaboration and innovation.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories