ನವೆಂ . 15, 2024 02:04 Back to list

14 bolt hub seal

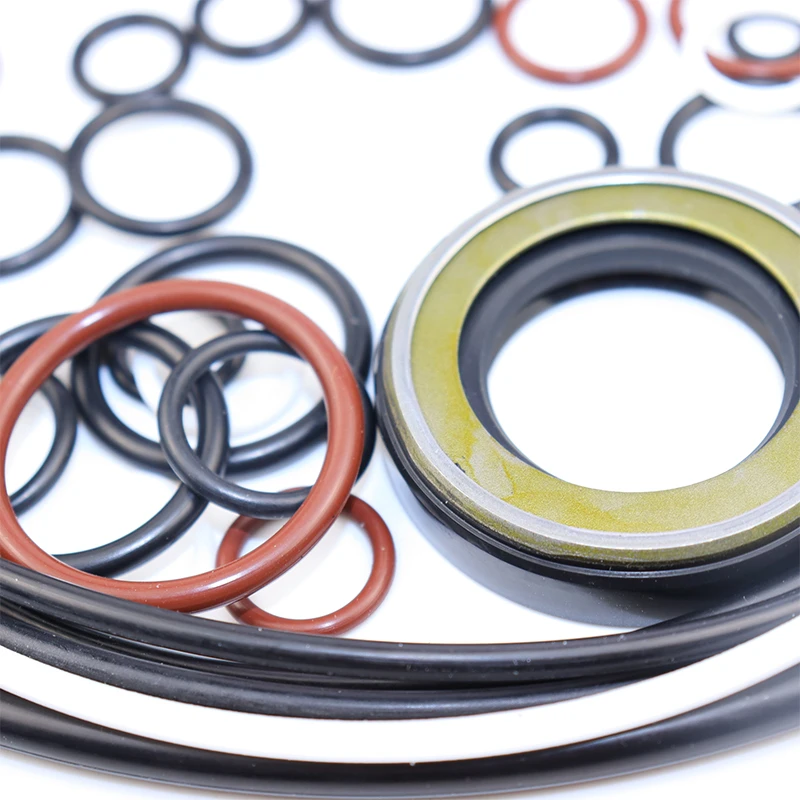

Understanding the 14% Bolt Hub Seal An Essential Component in Mechanical Reliability

The realm of mechanical engineering and automotive design is rich with components that play crucial roles in ensuring the functionality, reliability, and efficiency of machines and vehicles. Among these components is the 14% bolt hub seal, an often-overlooked element that significantly contributes to the performance and durability of various systems.

What is a Bolt Hub Seal?

A bolt hub seal, in essence, is a sealing device that is designed specifically to prevent the ingress of contaminants, such as dirt, moisture, and other foreign particles, into critical components of mechanical assemblies. The “14%” designation typically refers to a specific characteristic related to the sealing performance or design specifications, but understanding its importance requires a deeper dive into its functionality and applications.

Importance of Sealing Systems

In mechanical assemblies, especially in automotive applications, seals play a pivotal role in maintaining the integrity of the systems they protect. The failure of a seal can lead to significant issues, including fluid leaks, contamination of internal components, decreased efficiency, and ultimately, catastrophic failure of machinery. By ensuring a tight seal at the bolt hub area, these seals prevent lubricants from escaping and shield essential components from harmful external elements.

Applications of the 14% Bolt Hub Seal

The 14% bolt hub seal is commonly employed in various applications, including

14 bolt hub seal

1. Automotive Wheels and Hubs In vehicles, the wheel hub assembly is a critical area where the bolt hub seal is utilized. It protects the wheel bearings and maintains the lubricity of the grease contained within. A reliable seal ensures that the bearings are not compromised by dirt and moisture, which can lead to premature wear and failure.

2. Industrial Machinery Many types of machinery, from conveyor systems to heavy industrial equipment, rely on bolt hub seals to protect internal gears and bearings. These components are often subjected to harsh operating conditions, making robust sealing mechanisms essential for maintaining operational efficiency.

3. Aerospace Applications In the aerospace industry, the reliability of all components is paramount. Bolt hub seals in aircraft ensure the integrity of landing gear and other associated mechanisms, preventing fluid leaks that could lead to unsafe conditions.

The Technical Specifications

When discussing a 14% bolt hub seal, it is essential to acknowledge the materials and design parameters that contribute to its performance. Typically, these seals are manufactured from durable elastomers that can withstand a range of temperatures and pressures. The 14% might refer to a specific feature concerning the seal's thickness or its compression ratio when installed, providing an optimal balance between flexibility and resistance to wear.

The effectiveness of a bolt hub seal is also influenced by its design, including considerations such as lip geometry, the surface finish of opposing components, and the method of installation. A well-designed seal can offer significant longevity, reducing maintenance needs and extending the service life of the equipment it protects.

Conclusion

In summary, the 14% bolt hub seal, while often overlooked in broader discussions of machinery and design, plays a crucial role in maintaining system integrity and performance. Its applications span across various fields, from automotive to aerospace, demonstrating its versatility and necessity in modern engineering. By understanding the importance of such components, engineers and designers can better appreciate the intricate relationships between various parts of mechanical assemblies and strive for improvements that enhance reliability and efficiency. As we continue to push the boundaries of technology and design, components like the 14% bolt hub seal will remain vital in ensuring the functionality and longevity of our machines and vehicles.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories