តុលា . 18, 2024 11:43 Back to list

Seal Kit Pump Solutions for Efficient and Reliable Performance in Various Applications

Understanding Seal Kit Pumps A Comprehensive Overview

Seal kit pumps are essential components in various industrial applications, playing a vital role in ensuring the efficient and safe operation of equipment. These pumps are specifically designed to handle fluids, especially those that require a high level of sealing integrity to prevent leaks and ensure optimal performance. In this article, we will explore the significance of seal kit pumps, their applications, maintenance, and the different types available in the market.

What is a Seal Kit Pump?

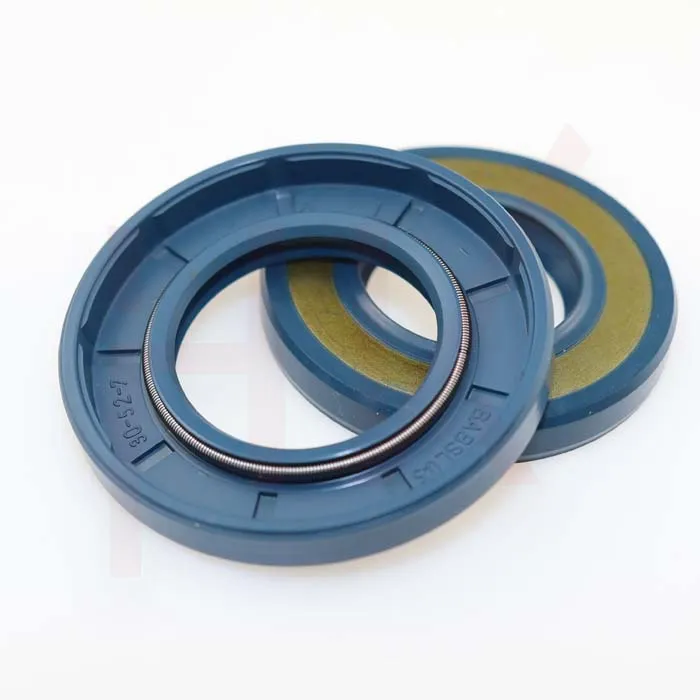

A seal kit pump refers to a pumping device that includes various sealing components designed to prevent fluid escape and protect the pump from contamination. These kits are crucial in maintaining the pump’s efficiency and reliability, particularly in applications involving high pressures or hazardous materials. The main components of a seal kit typically include O-rings, seals, gaskets, and other sealing elements that fit specific pump designs.

Importance of Seal Kit Pumps

Seal kit pumps are integral to many industries, including oil and gas, pharmaceuticals, food processing, and wastewater management. Their primary functions include

1. Preventing Fluid Leakage Seal kits are engineered to provide tight seals that prevent any fluid from leaking out of the system, which is essential for safety and environmental protection.

2. Maintaining System Integrity Proper sealing is crucial for the overall efficiency of the pump. Leaks can lead to loss of pressure, which can affect the entire system’s performance.

3. Reducing Downtime Well-maintained seal kits help to minimize unexpected pump failures, reducing downtime and maintenance costs. This reliability is critical in industries where continuous operation is necessary.

Applications of Seal Kit Pumps

Seal kit pumps can be found in various applications across multiple sectors

- Oil and Gas The exploration and extraction processes require robust sealing to handle high pressures and prevent spills.

- Chemical Processing Pumps used in chemical applications need precise sealing to handle corrosive substances without risk of leaks.

- Water Treatment In municipal and industrial water treatment facilities, seal kit pumps ensure the safe transport of water and chemicals.

- Manufacturing Seal kits are used in hydraulic systems, where the integrity of the seal is crucial for operational effectiveness.

seal kit pump

Types of Seal Kits

There are several types of seal kits available, each designed to meet specific industry requirements

1. Hydraulic Seal Kits These kits are specifically designed for hydraulic systems to handle high pressures and provide resistance to oil and various hydraulic fluids.

2. Mechanical Seal Kits Commonly used in pumps, these seals are designed to prevent the leakage of fluids in applications like water and sewage treatment.

3. O-Ring Kits Versatile and widely used, O-rings can be utilized in various applications, from automotive to aerospace.

4. Custom Seal Kits Some manufacturers offer customized seal kits tailored to specific applications and pump types, ensuring that performance standards are met.

Maintenance Tips for Seal Kit Pumps

To ensure the longevity and efficiency of seal kit pumps, regular maintenance and inspection are critical. Here are some maintenance tips

- Routine Inspections Regularly check the seals for wear and tear. Look for signs of leakage or deterioration, which could indicate it’s time for a replacement.

- Proper Installation Ensure that seals are installed correctly according to manufacturer specifications to prevent early failure.

- Fluid Compatibility Always use fluids that are compatible with the sealing materials to avoid chemical degradation.

- Environmental Considerations Consider the operating environment; extreme temperatures and pressures can affect seal performance.

Conclusion

Seal kit pumps are indispensable in industrial applications, offering the reliability needed for safe and efficient fluid management. By understanding their significance, applications, and maintenance, industries can ensure optimal pump performance and longevity. Investing in quality seal kits and adhering to proper maintenance practices will not only enhance efficiency but also contribute to operational success across various sectors.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories