វិច្ឆិកា . 24, 2024 13:51 Back to list

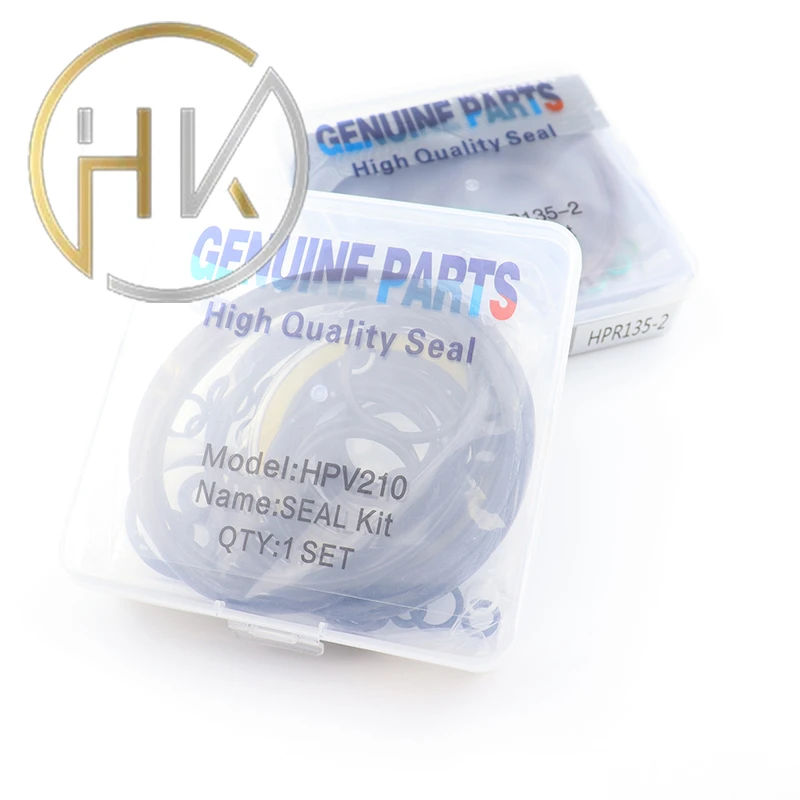

seal kit hydraulic

Understanding Seal Kit Hydraulics Essential Components for Efficiency

In the world of hydraulic systems, seal kits play a critical role in ensuring that equipment operates smoothly and efficiently. A hydraulic seal kit is an assembly of seals and components designed to prevent fluid leakage, maintain pressure, and protect the internal mechanisms of hydraulic machinery. This article will explore the importance of seal kits in hydraulic applications, their components, and how to maintain them for optimal performance.

Hydraulic systems are commonly found in a variety of machinery, including construction equipment, automotive systems, and industrial machines. These systems rely on fluid mechanics to transfer power and perform work. However, the effectiveness of these systems hinges on the integrity of their seals. Over time, exposure to high pressures, temperatures, and harsh chemicals can deteriorate these seals, leading to leaks and reduced efficiency.

Components of a Seal Kit

A typical hydraulic seal kit may include various types of seals, such as O-rings, backup rings, rod seals, piston seals, and wipers. Each component serves a specific purpose

1. O-rings These are circular seals used to create a barrier between two mating surfaces, preventing fluid from escaping. They are versatile and can be used in dynamic and static applications.

2. Rod seals These are designed to seal the rod of a hydraulic cylinder as it extends and retracts. They prevent fluid leakage while allowing for smooth movement.

seal kit hydraulic

4. Wipers Wipers are used to prevent contaminants and debris from entering the hydraulic system, protecting the internal components from wear and damage.

5. Backup rings These are used in conjunction with O-rings and other seals to provide additional support, especially in high-pressure applications.

Maintenance and Replacement

Regular maintenance of hydraulic seal kits is essential to ensure the long-term functionality of hydraulic systems. Routine inspections should be conducted to check for signs of wear, such as cracks, deformation, or discoloration. If any damage is observed, it is advisable to replace the seals promptly to avoid costly repairs or downtime.

Additionally, using the correct seal materials is crucial for the application at hand. Factors such as temperature, pressure, and the type of fluid being used should influence your choice of seals. Materials such as nitrile, polyurethane, and fluorocarbon are common, but selecting the right one depends on the specific requirements of your hydraulic system.

In conclusion, seal kits are vital for the efficient operation of hydraulics, preventing leaks and ensuring that pressure is maintained within the system. By understanding their components and implementing a robust maintenance strategy, operators can enhance the reliability and longevity of hydraulic machinery. Investing in high-quality seal kits and regular inspections will ultimately lead to improved productivity and reduced operational costs.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories