ធ្នូ . 04, 2024 23:40 Back to list

Replacing Seals in Hydraulic Cylinders for Improved Performance and Durability

Replacing Seals in a Hydraulic Cylinder A Step-by-Step Guide

Hydraulic cylinders are vital components in various machines and equipment, providing powerful linear motion for tasks ranging from lifting and pushing to pressing and bending. Over time, the seals within these cylinders can wear out, leading to leaks and decreased efficiency. Replacing seals is an essential maintenance task that ensures the hydraulic system operates smoothly. This article will guide you through the steps involved in replacing seals in a hydraulic cylinder, ensuring you can perform this task safely and effectively.

Understanding Hydraulic Seals

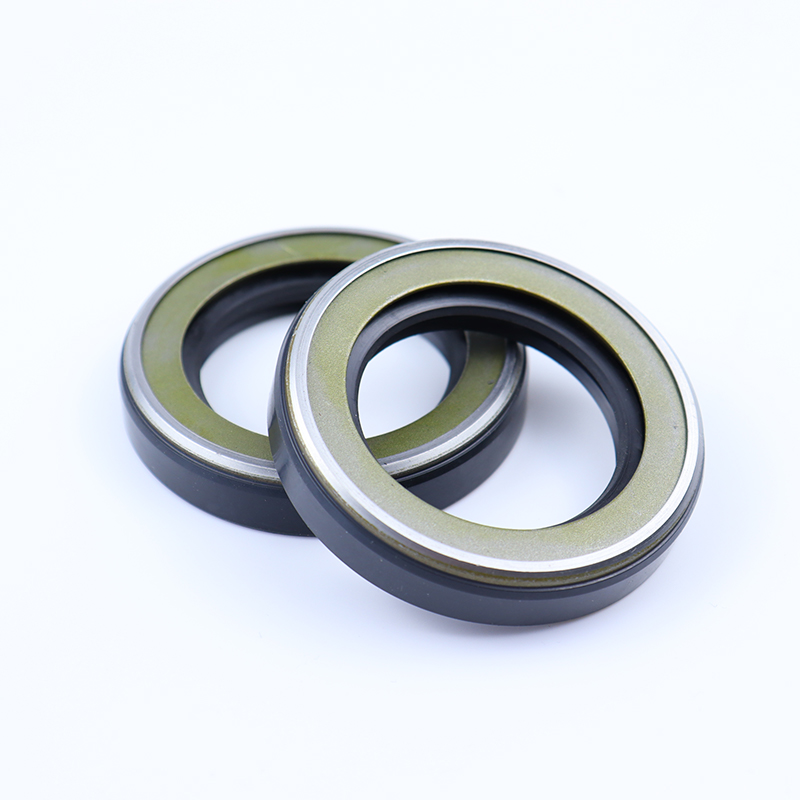

Before diving into the replacement process, it is important to understand what seals do in a hydraulic cylinder. Seals prevent hydraulic fluid from leaking out of the cylinder and keep contaminants from entering the system. Common types of seals used in hydraulic cylinders include O-rings, rod seals, and piston seals. These components are designed to withstand high pressure and temperature while maintaining their integrity over time. However, factors such as improper installation, contamination, or extreme operating conditions can lead to seal deterioration.

Tools and Materials Needed

To begin, you will need several tools and materials - Safety goggles and gloves - A hydraulic cylinder repair kit (including replacement seals) - Wrenches or socket set - Screwdrivers - A clean work surface - Hydraulic fluid - Lubricant for seals

Step-by-Step Process

1. Preparation and Safety First Before working on the hydraulic cylinder, ensure the machine is powered down and isolated from any power sources. Release any residual pressure within the hydraulic system to prevent accidents during disassembly. Wear safety goggles and gloves to protect yourself from hydraulic fluid.

2. Remove the Cylinder Disconnect the hydraulic cylinder from the machine. Use the appropriate wrenches to detach it from its mounting brackets and unhook any hydraulic lines. Be prepared to catch any fluid that may spill during this process.

replacing seals in a hydraulic cylinder

3. Disassemble the Cylinder With the hydraulic cylinder on a clean work surface, remove the end caps using a wrench or screwdriver. Take note of how the components are arranged to ensure correct reassembly. Carefully slide out the piston and rod from the cylinder.

4. Inspect Components Before replacing the seals, inspect the piston, rod, and cylinder for any signs of damage or wear. Consider replacing any components that exhibit significant wear as they can compromise the new seals.

5. Replace the Seals Carefully remove the old seals from the piston and rod. It is crucial to prevent scratching the surfaces during this process. Clean the sealing surfaces thoroughly before installing the new seals. Apply a thin layer of lubricant to the new seals to facilitate easier installation and prevent damage.

6. Reassemble the Cylinder After the new seals are in place, reinsert the piston and rod into the cylinder. Ensure that they are positioned correctly based on your initial observations. Reattach the end caps securely, taking care not to overtighten and damage the new seals.

7. Reinstall the Cylinder Once the cylinder is reassembled, it is time to reinstall it onto the machine. Reconnect the hydraulic lines and mount the cylinder securely in place.

8. Test the System Before returning the machine to full operation, it's essential to conduct a test run. Gradually apply pressure to the hydraulic system and check for any leaks around the newly installed seals. If everything appears to be functioning correctly, you can proceed with normal operations.

Conclusion

Replacing seals in a hydraulic cylinder is a crucial maintenance task that can significantly extend the life of the hydraulic system while improving its efficiency. Following the outlined steps ensures that you perform the task safely and effectively. Regular maintenance, including seal replacement, will help prevent costly repairs and downtime, keeping your machinery running smoothly for years to come.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories