មករា . 26, 2025 07:26 Back to list

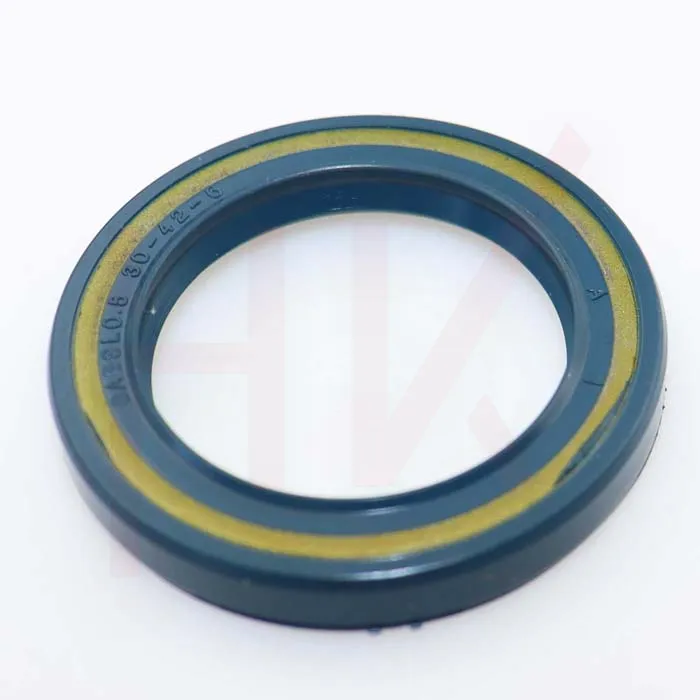

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Trustworthiness in radial shaft seal manufacturing stems from adherence to international quality standards and certifications. Manufacturers must comply with ISO 9001 for quality management systems, ensuring that each seal meets predetermined criteria. In addition, certifications like the American Society of Mechanical Engineers (ASME) and the Society of Automotive Engineers (SAE) further reinforce confidence in the product's performance capabilities. From an experiential perspective, the success of radial shaft seals is visible across numerous applications. In the automotive sector, these seals are crucial in maintaining engine integrity, reducing oil consumption, and enhancing vehicle performance. Similarly, in industrial machinery, radial shaft seals contribute to the seamless operation of pumps, compressors, and gearboxes, fortifying the machinery against breakdowns and maintenance downtime. Environmental sustainability also weaves into the narrative of radial shaft seals. As industries pivot towards eco-friendly practices, the demand for seals that support this transition grows. Modern seals are engineered not only to perform under stringent conditions but also to align with environmental directives by minimizing lubricant leakage, thereby reducing ecological impact. In conclusion, radial shaft seals represent a confluence of engineering skill and technological advancement. They reflect a commitment to excellence, underscored by decades of innovation, stringent adherence to quality, and a genuine contribution to operational efficiency. For industries that rely on high-performing machinery, these seals are indispensable. By embracing new materials, leveraging advanced design tools, and maintaining rigorous quality standards, radial shaft seal manufacturers continue to bolster their reputation for reliability and trustworthiness, securing their place at the forefront of industrial solutions.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories