ធ្នូ . 02, 2024 03:15 Back to list

radial shaft seals

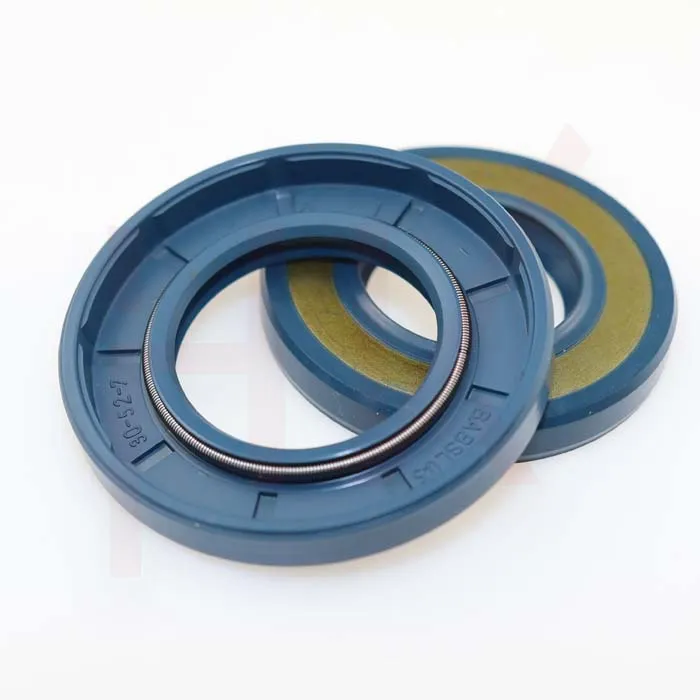

Understanding Radial Shaft Seals Functionality, Types, and Applications

Radial shaft seals, often referred to as rotary shaft seals, play a crucial role in many mechanical systems, ensuring the reliability and longevity of rotating machinery. These essential components are designed to prevent lubricant leakage and protect internal parts from external contaminants, such as dust, dirt, and moisture. This article delves into the functionality, types, and applications of radial shaft seals to provide a comprehensive overview.

Functionality of Radial Shaft Seals

At their core, radial shaft seals are engineered to create a tight seal around rotating shafts. They consist of a flexible elastomeric material (often rubber) that forms a lip, which presses against the shaft surface. This design allows the seal to accommodate the shaft's movement while maintaining a barrier that prevents fluids from leaking out and contaminants from entering.

Radial shaft seals operate under varying pressures and temperatures, making their material composition critical. High-quality seals can withstand extreme conditions, such as high-speed rotations and harsh environmental factors. The effectiveness of a radial shaft seal is generally determined by its ability to

1. Contain Fluids They keep lubricants or hydraulic fluids contained within the machinery, which is vital for efficient operation and performance.

2. Exclude Contaminants By preventing external materials from entering the sealed environment, radial shaft seals protect sensitive components, thereby reducing wear and extending life expectancy.

3. Accommodate Movement As shafts rotate and move, the seals must adjust without losing their sealing capacity, ensuring continuous protection.

Types of Radial Shaft Seals

Radial shaft seals come in various designs to suit different applications and environmental conditions. Some common types include

1. Single Lip Seals These are the most frequently used type, featuring a single sealing lip that contacts the shaft. They are ideal for low-pressure, non-dynamic applications.

2. Double Lip Seals Equipped with two sealing lips, double lip seals offer enhanced protection by providing an additional barrier against contaminants. They are commonly used in environments with higher pressures or where contamination is likely.

radial shaft seals

3. Spring-Loaded Seals These seals incorporate springs that maintain constant pressure on the sealing lip, compensating for wear and maintaining effectiveness over time.

4. V-Rings These are adaptable seals that can be fitted onto the shaft without a housing. They work well for applications with minimal space and provide effective sealing against dirt and moisture.

5. Specialty Seals Certain applications require seals made from advanced materials such as PTFE or fluorosilicone, which can withstand aggressive chemicals and extreme temperatures.

Applications of Radial Shaft Seals

Radial shaft seals are utilized in a broad range of industries and applications, ranging from automotive to industrial machinery. Common areas include

- Automotive Engineering In vehicles, radial shaft seals are essential for preventing oil leaks in engines and ensuring that transmission fluids remain contained.

- Manufacturing Machinery Equipment like pumps, motors, and conveyors rely on effective sealing to maintain lubricant levels and protect against debris.

- Aerospace Applications In aviation, these seals protect critical engine components from extreme temperatures and contaminants at high altitudes.

- Hydraulic Systems Hydraulic cylinders and pumps use radial shaft seals to minimize fluid leakage and preserve system efficiency.

Conclusion

In summary, radial shaft seals are indispensable components in mechanical systems that revolve around rotating shafts. By effectively containing fluids and keeping contaminants at bay, they ensure machinery operates smoothly and reliably. With various types available to suit different needs, understanding their functionalities and applications can aid engineers and technicians in selecting the right seals for their specific requirements, ultimately prolonging the life and performance of their equipment. As technology advances and new materials are developed, the future of radial shaft seals looks promising, with enhanced performance and durability on the horizon.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories